Exhaust gas cleaning catalyst

A technology of exhaust gas purification and catalyst, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, molecular sieve catalyst, etc. It can solve the problems of unavoidable cost and increase, and achieve the effect of good efficiency and effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

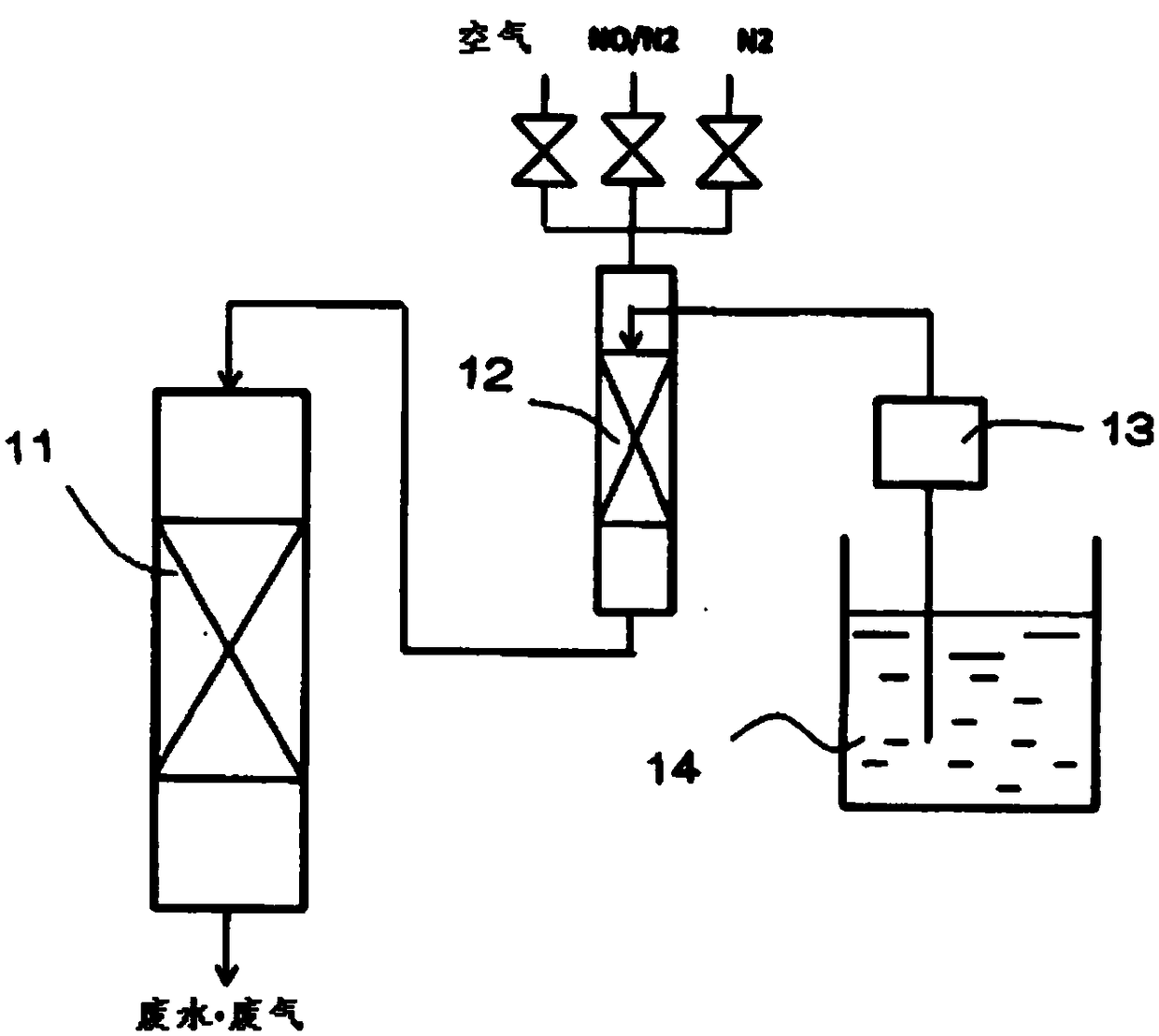

Embodiment 1

[0080] A FER-type zeolite (manufactured by TOSOH CORPORATION) having a value (S) of 1528 was used.

[0081] 1.45 g of bismuth nitrate hexahydrate was added to 40 g of ion-exchanged water to prepare a suspension, and the suspension was heated to 80°C. 10 g of the above-mentioned zeolite was immersed in the suspension maintained at this temperature for 15 hours to perform ion exchange. After the ion exchange, it was taken out from the aqueous solution, washed with 440 mL of ion-exchanged water, and dried at 80° C. for 12 hours to obtain the target catalyst.

Embodiment 2

[0083] A catalyst supported by a FER type zeolite (manufactured by TOSOH CORPORATION) having a value (S) of 1766 was prepared. The preparation steps used to prepare the catalyst were the same as in Example 1 except that the zeolite was replaced.

Embodiment 3

[0085] A catalyst supported by a FER type zeolite (manufactured by TOSOH CORPORATION) having a value (S) of 2323 was prepared. The procedure used to prepare the catalyst was the same as in Example 1 except that the zeolite was replaced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com