Plug-in connector part with cooled contact elements

A technology of contact elements and connectors, which is applied to parts, connections, vehicle parts, etc. of connection devices, and can solve the problem of limited expansion of contact elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

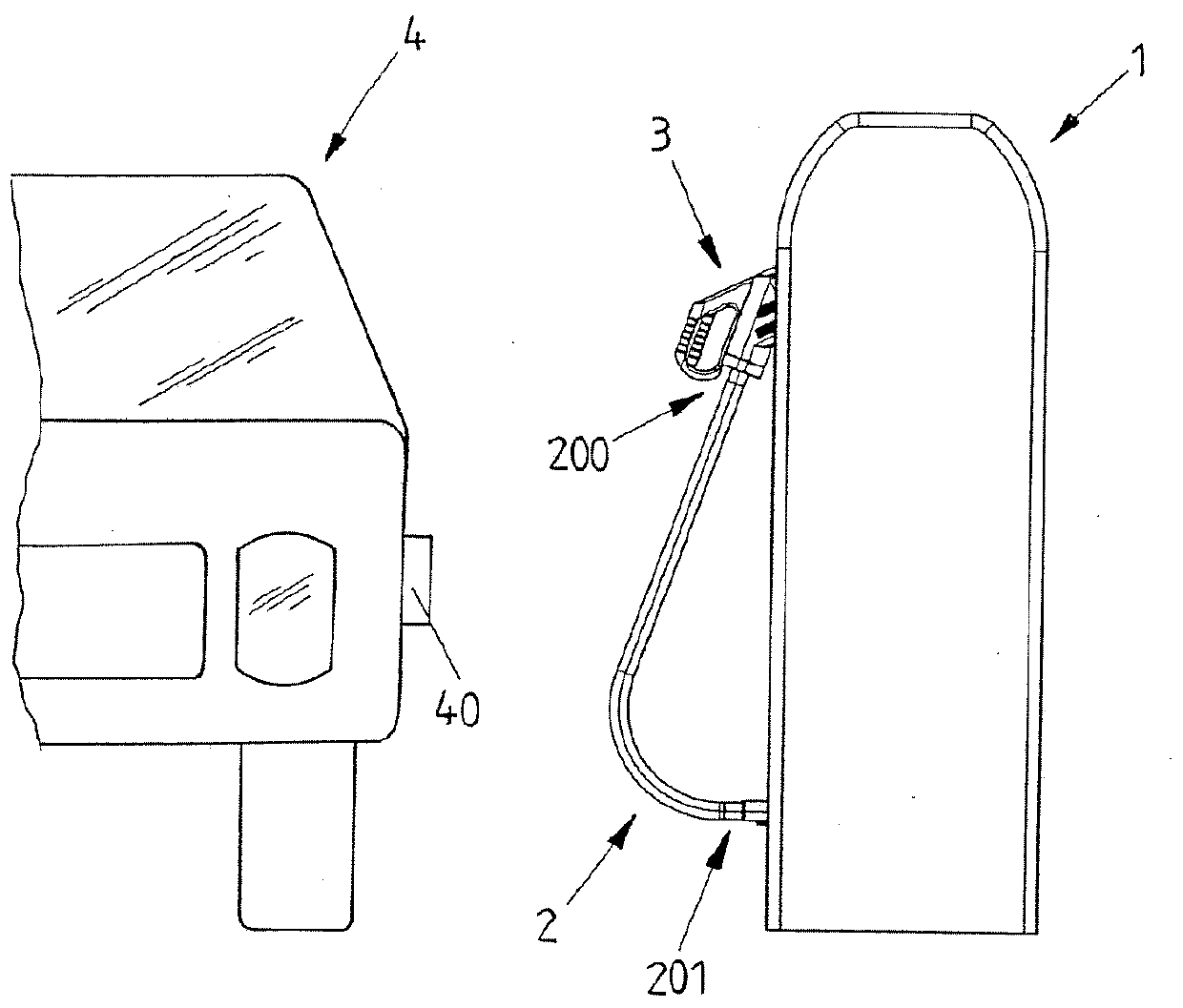

[0041] figure 1 A charging station 1 is shown for charging an electrically driven vehicle 4 (also called an electric vehicle). The charging station 1 is designed to supply a charging current in the form of alternating current or direct current and has a cable 2 which is connected at one end 201 to the charging station 1 and at the other end 200 to a plug-in connector part 3 in the form of a charging plug.

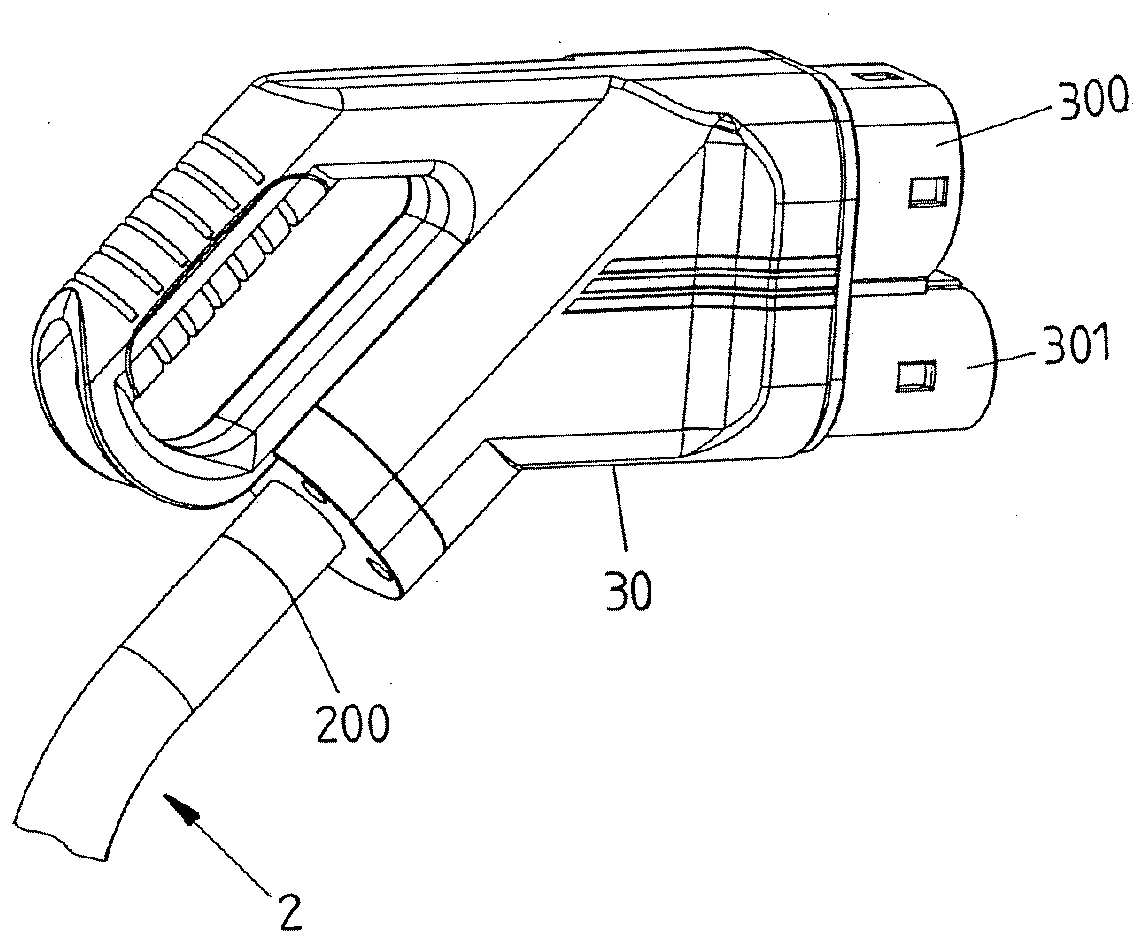

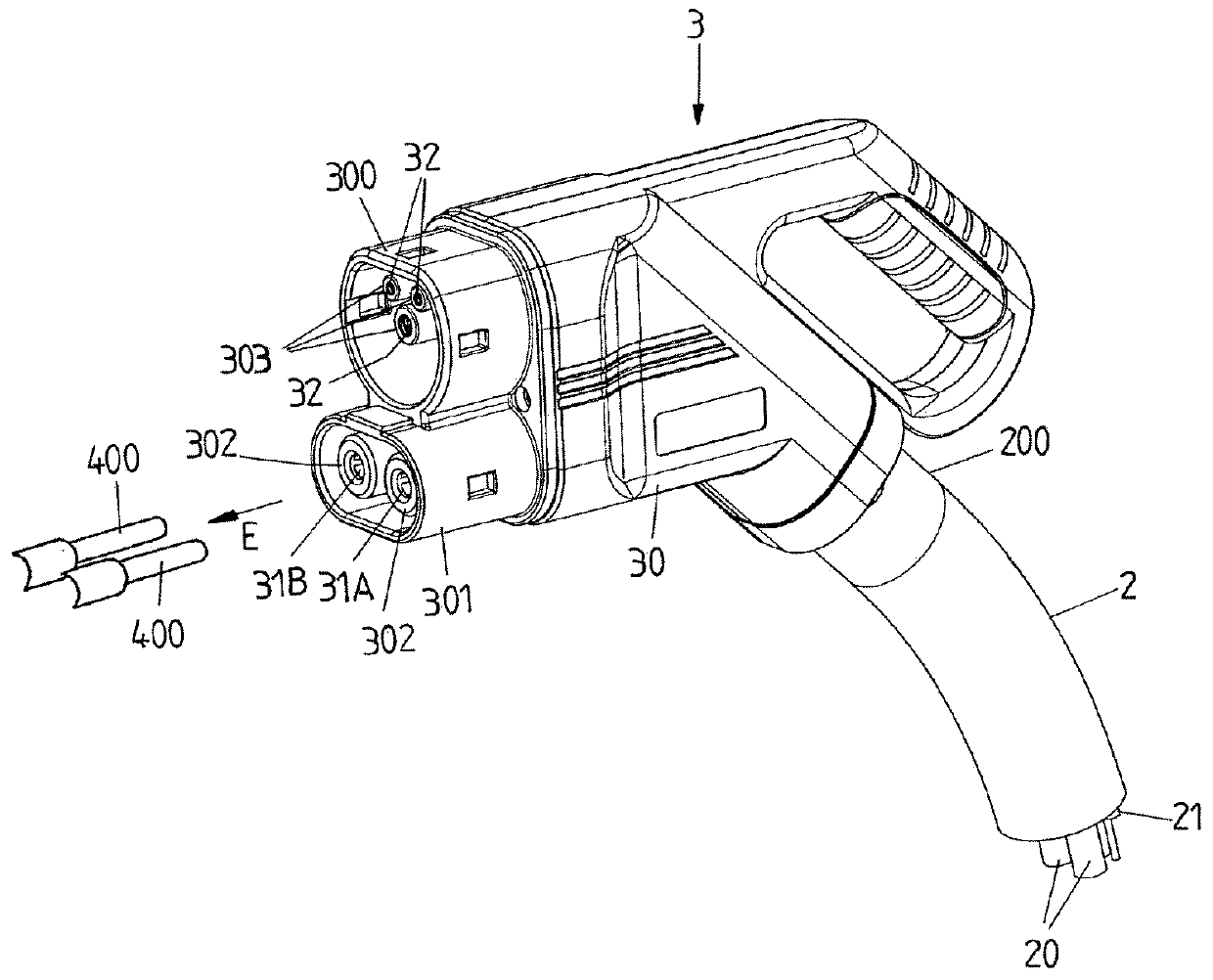

[0042] From figure 2 It can be seen from the enlarged view that the plug-in connector part 3 has plug-in parts 300, 301 on the housing 30, with which the plug-in connector part 3 can be paired with a corresponding charging socket on the vehicle 4. The plug connector parts 40 are engaged. This makes it possible to electrically connect the charging station 1 to the vehicle 4 in order to transmit charging current from the charging station 1 to the vehicle 4 .

[0043] In order to ensure fast charging of the electric vehicle 4 , for example in a so-called fast charging proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com