Flat peach freeze-drying method

A production method, the technology of flat peaches, applied in food drying, food freezing, food preservation, etc., can solve the problems of prolonging the storage period and sales period, increasing the output value of peach farmers and peach orchards, etc., to achieve additional profits, light weight, and maximum value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

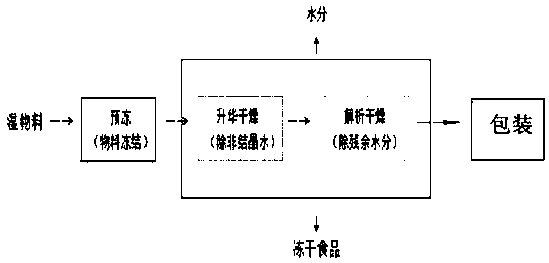

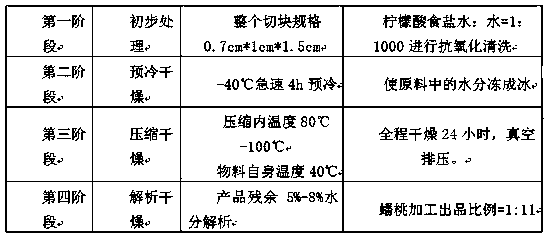

[0025] The preparation method of flat peach freeze-drying comprises the steps:

[0026] Step 1: Preliminary treatment: Peel and remove the core of the flat peaches, cut the flat peaches into regular blocks of 0.7cm*1cm*1.5cm, soak them in the mixed liquid of citric acid and salt, citric acid salt water: water = 1:1000 , to prevent the oxidation of the flat peach pulp, take it out of the mixture and rinse it with clean water;

[0027] Step 2: Pre-cooling and drying: Put the raw materials initially treated in step 1 in the freezing chamber for rapid freezing, the freezing temperature is controlled at minus -40°C, and the initial pre-cooling work is completed in 4 hours; the pre-cooling stage makes the water in the raw materials Turn into ice to prepare for the next stage of sublimation. The temperature must reach below the freezing point of the material. Different materials have different freezing points. The speed of freezing is directly related to the size of the ice crystal p...

Embodiment 2

[0032] The preparation method of flat peach freeze-drying comprises the steps:

[0033] Step 1: Preliminary treatment: Peel and remove the core of the flat peaches, cut the flat peaches into regular blocks of 0.7cm*1cm*1.5cm, soak them in the mixed liquid of citric acid and salt, citric acid salt water: water = 1:1000 , to prevent the oxidation of the flat peach pulp, take it out of the mixture and rinse it with clean water;

[0034] Step 2: Pre-cooling and drying: Put the raw materials initially treated in step 1 in the freezing chamber for rapid freezing, the freezing temperature is controlled at minus -40°C, and the initial pre-cooling work is completed in 4 hours; the pre-cooling stage makes the water in the raw materials Turn into ice to prepare for the next stage of sublimation. The temperature must reach below the freezing point of the material. Different materials have different freezing points. The speed of freezing is directly related to the size of the ice crystal p...

Embodiment 3

[0039] The preparation method of flat peach freeze-drying comprises the steps:

[0040] Step 1: Preliminary treatment: Peel and remove the core of the flat peaches, cut the flat peaches into regular blocks of 0.7cm*1cm*1.5cm, soak them in the mixed liquid of citric acid and salt, citric acid salt water: water = 1:1000 , to prevent the oxidation of the flat peach pulp, take it out of the mixture and rinse it with clean water;

[0041] Step 2: Pre-cooling and drying: Put the raw materials initially treated in step 1 in the freezing chamber for rapid freezing, the freezing temperature is controlled at minus -40°C, and the initial pre-cooling work is completed in 4 hours; the pre-cooling stage makes the water in the raw materials Turn into ice to prepare for the next stage of sublimation. The temperature must reach below the freezing point of the material. Different materials have different freezing points. The speed of freezing is directly related to the size of the ice crystal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com