Irregular and normal outer chain board mixing assembling device

A technology of mixed assembly and outer chain plate, applied in the direction of metal chains, etc., can solve the problems of easy failure, many links, precision control and processing speed limit, etc., to achieve convenient assembly and control, simple control structure and strong stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

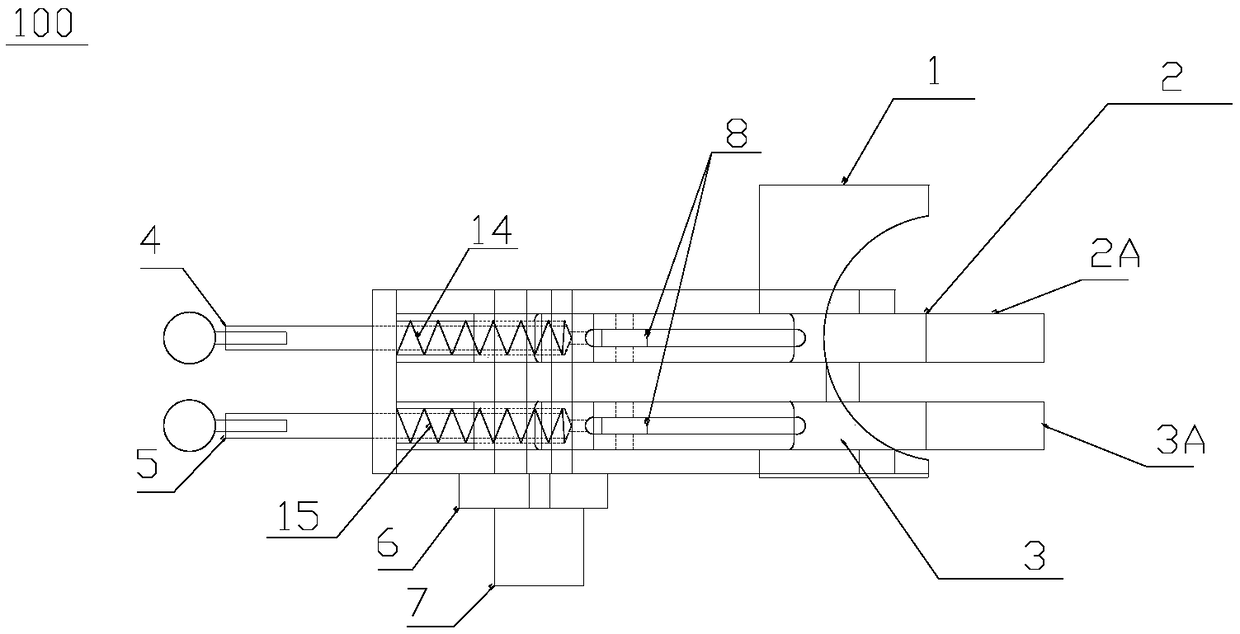

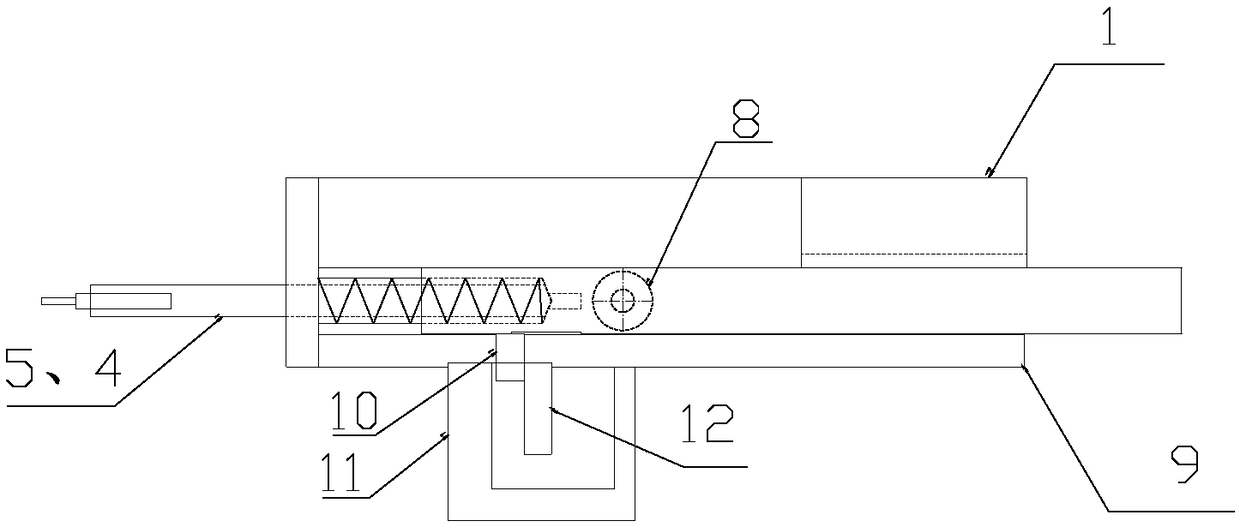

[0091] The difference between this embodiment and Embodiment 1 is that the slider blocking mechanism includes a slider switch part 125 fixed on one side of the slider fixed mold 1, and the slider switch part 125 is pivotally connected to the first slider 2 On the slider fixed mold 1 between the second slider 3, a torsion spring 126 is provided on the pivot shaft of the slider switch part 125, and the torsion spring 126 provides locking for the slider switch part 125. One side of the slider switch 125 is provided with a switch driver 121 , and the switch driver 121 drives the side of the slider switch 125 to overcome the force of the torsion spring 126 to lock and slide the second slider 3 .

[0092] The first slider 2 and the second slider 3 are respectively provided with corresponding grooves or stop protrusions 124 . The groove or the stopper protrusion 124 is in contact with the locking end 122 at both ends of the slider switch part 125, and the deadlock end 122 and the gro...

Embodiment 3

[0094] The difference between this embodiment and Embodiment 1 is that the first slider 2 and the second slider 3 are respectively provided with drive cylinders A131 on the opposite ends of the first lower chain push plate 2A and the second lower chain push plate 3A. and drive cylinder B132, the drive cylinder A131 and the drive cylinder B132 drive the slider to reciprocate, and a shaft hole is provided between the ends of the first lower chain plate push plate 2A and the second lower chain plate push plate 3A Connected to the rotatable triangular block 133 of the slider fixed mold 1, the triangular block 133, the distance between any corner of the triangular block 133 and the side corresponding to the corner is greater than that of the first lower chain plate push plate 2A and the second lower chain plate The distance from the opposite surface of the push plate 3A, the distance from the center of the shaft hole connection of the triangular block 133 to any side is smaller than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com