Casting method of thruster shroud with widely different wall thickness

A technology with a large difference and a shroud, which is applied in the direction of casting molding equipment, casting molds, and casting mold components, can solve the problems of easy closing of feeding channels, fast cooling speed, and affecting the self-feeding effect of castings, etc., to achieve improved Anti-distortion ability of graphite, ensure the spheroidization rate of molten iron, and enhance the effect of self-feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] A method for casting a thruster shroud with widely different wall thicknesses, comprising the following steps:

[0039] 1. Mold making, making wooden molds according to the shape and inner cavity size of the shroud. The shape of the inner cavity is made, and a backing plate is provided on the outer side of the upper end of the wooden mold, and the thickness of the backing plate is the same as the height of the lifting of the shroud.

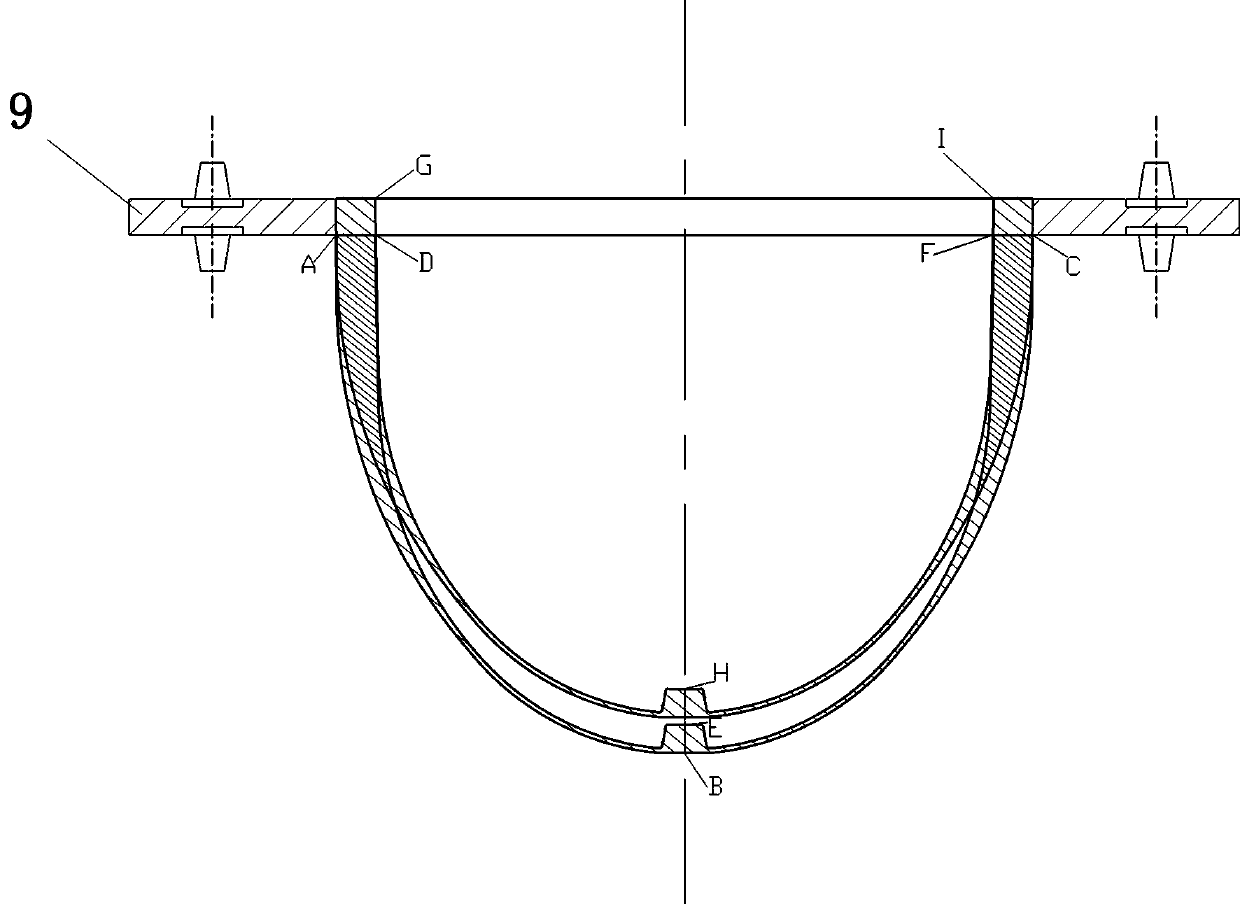

[0040] Such as figure 1 As shown, when the wooden mold is made, the shape is made according to the arc ABC of the shape of the shroud, and the inner cavity is made according to the radian of the inner cavity corresponding to the 100mm lift of the shroud as a whole, that is: from point D to point G, from point E to Point H, point F to point I; at this time, the thickness of the bottom of the wooden form is 113mm, and the thickness of the upper end of the wooden form is 107mm. The thickness of the entire wooden form is basically the same, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com