Vertical numerical control gear chamfering machine

A technology of chamfering machine and gear, applied in the direction of gear cutting machine, gear tooth manufacturing device, belt/chain/gear, etc. The effect of good processing quality and easy adjustment and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with specific examples, and the following examples are only descriptive, not limiting, and cannot limit the protection scope of the present invention with this.

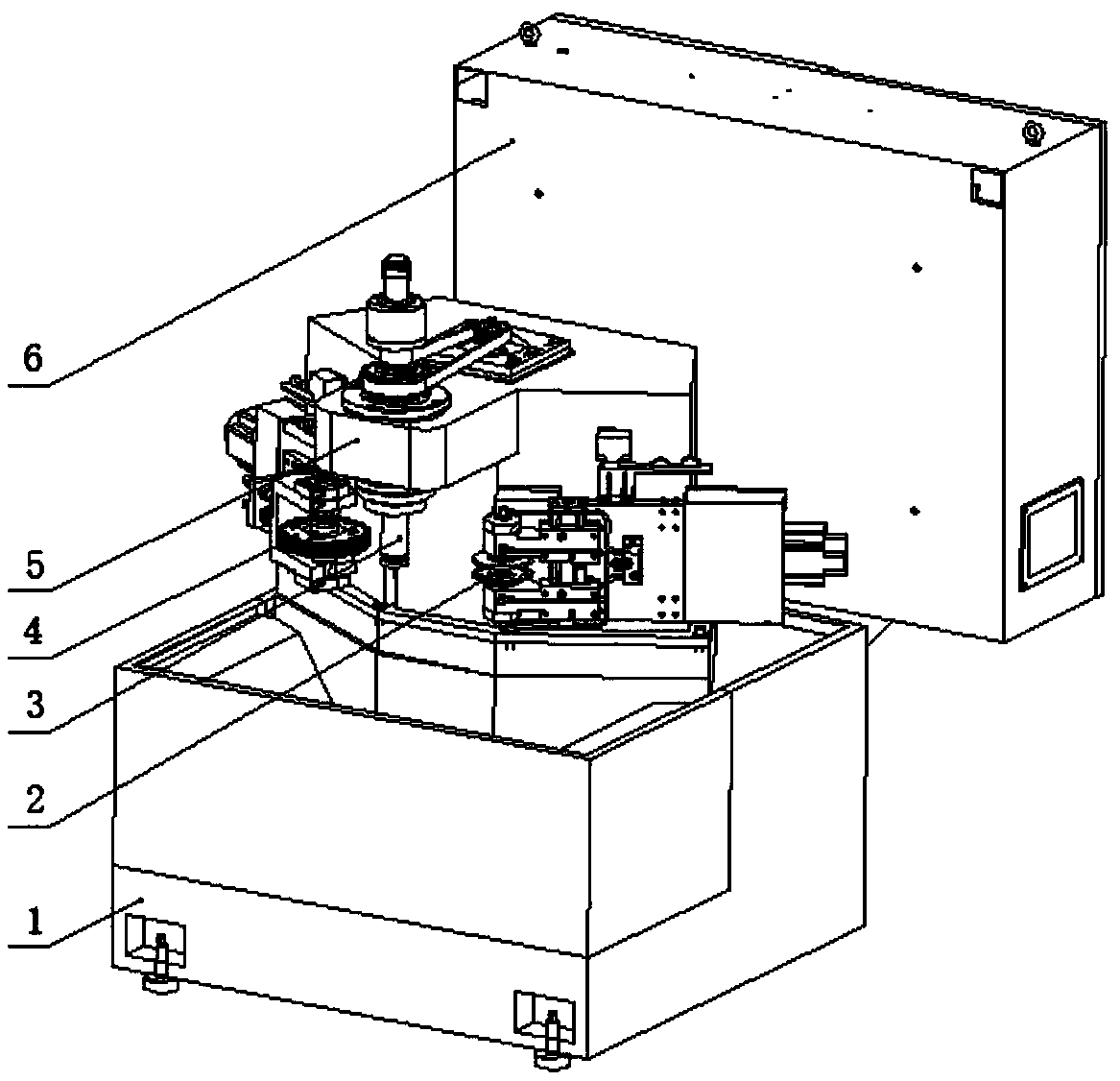

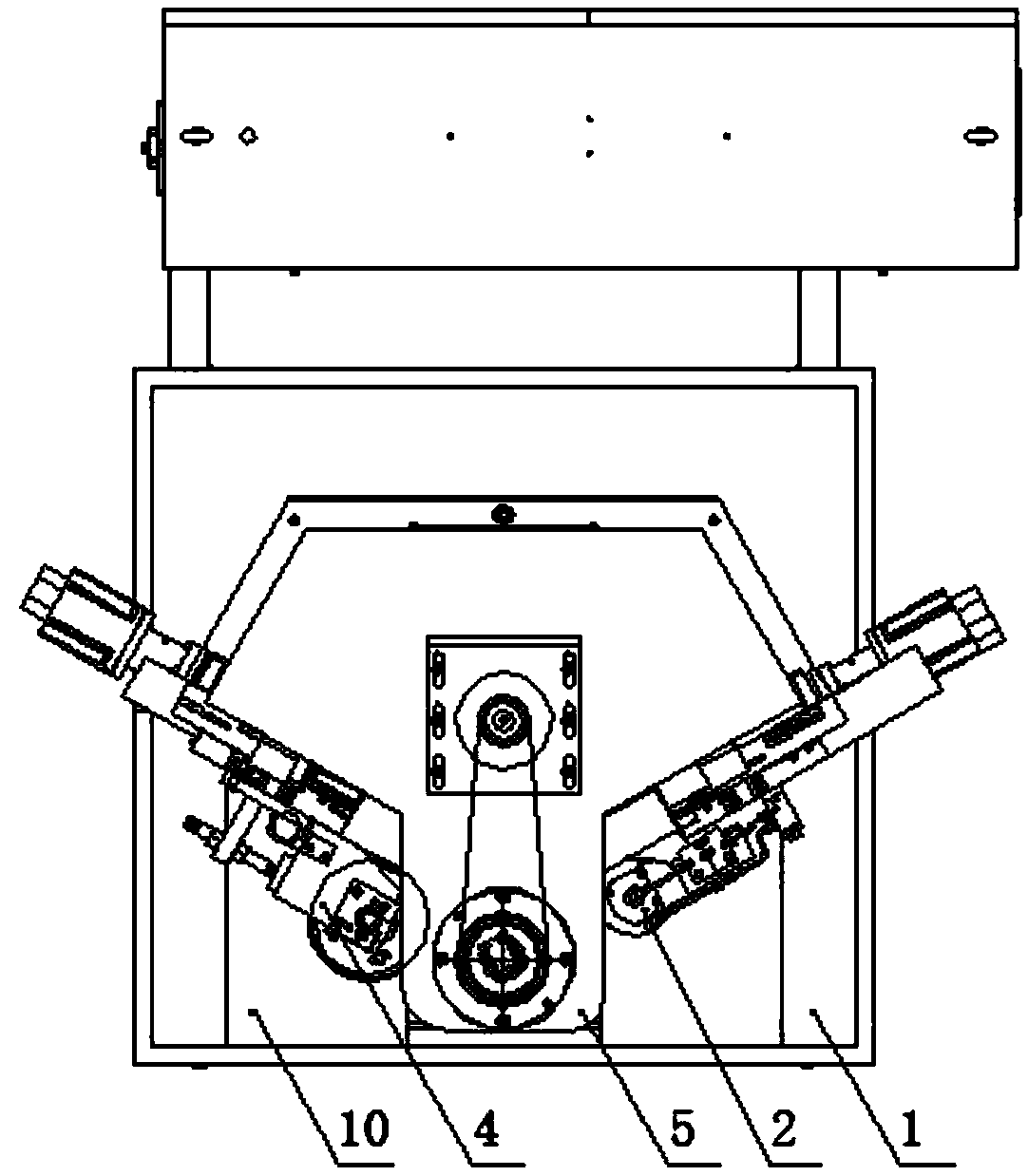

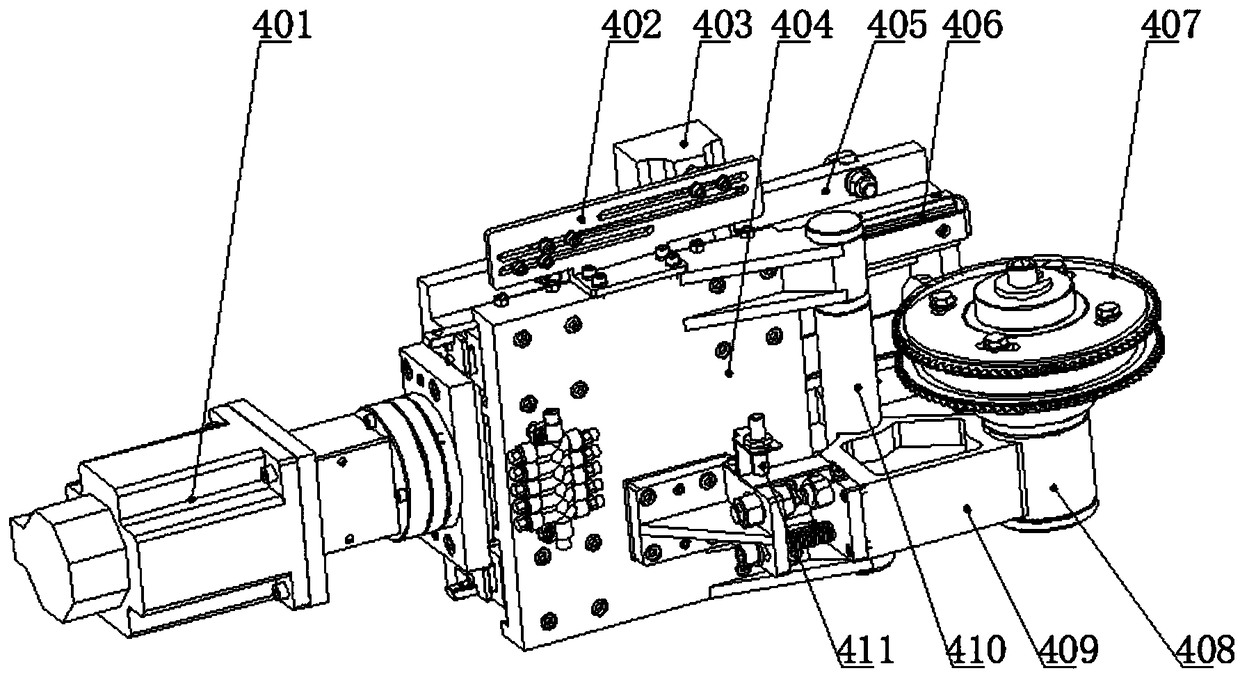

[0029] A vertical numerical control gear chamfering machine, comprising a machine base 1, a stand 5, a workpiece fixture mechanism 3, a tool mechanism 4 and a deburring mechanism 2, the machine base 1 is fixed with a stand 5, and the front end of the stand is formed with a A cantilever bracket that extends horizontally and longitudinally forward, and a workpiece clamp mechanism 3 is vertically installed on the cantilever bracket. shaft rotation;

[0030] The tool mechanism 4 and the deburring mechanism 2 are respectively installed on the vertical stands on both sides of the workpiece fixture mechanism. The installation axis forms an included angle of 120° with the cantilever bracket, which makes the plane layout of the equipment mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com