A robotic arm for product transfer

A technology of robotic arms and products, applied in the directions of manipulators, manufacturing tools, chucks, etc., can solve problems such as damage, limited application scope, and weak suction, and achieve the effect of easy adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

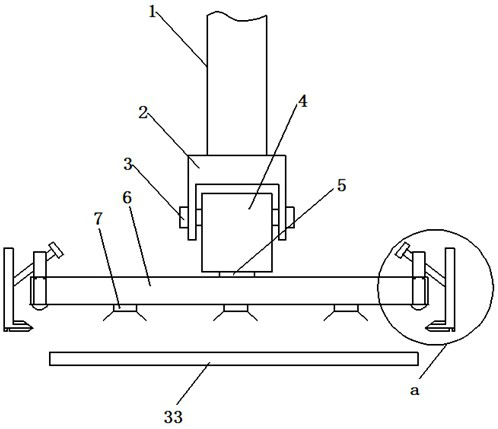

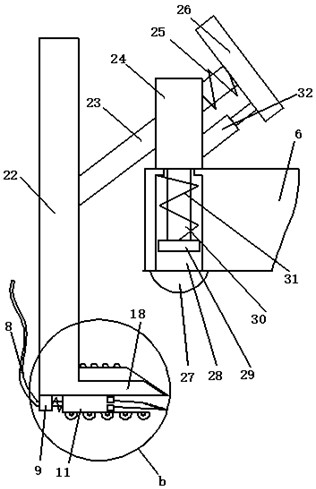

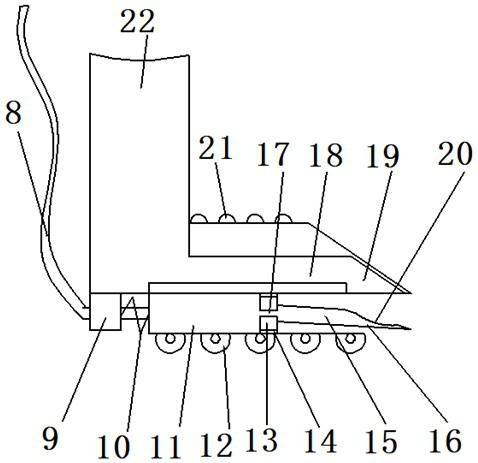

[0021] refer to Figure 1-4, a specific embodiment of the present invention includes a mechanical arm body 1, a first connecting block 4 is movably connected to the lower part of the mechanical arm body 1 through a first connecting arm 2 and a rotating shaft 3, and the lower part of the first connecting block 4 is connected through a rotating shaft 5 A support plate 6 is movably connected, and several suction cups 7 are fixedly connected to the bottom of the support plate 6. The two sides of the support plate 6 are respectively connected with a second fixed block 24, and a first connecting rod is movably inserted on the second fixed block 24. 23. The angle between the first connecting rod 23 and the second fixing block 24 is 45°, the inner side of the first connecting rod 23 is fixedly connected with the third fixing block 26, and the third fixing block 26 and the second fixing block 24 A cylinder 32 and a second spring 25 are connected between them. The second spring 25 is sl...

Embodiment 2

[0024] In this embodiment, on the basis of Embodiment 1, further improvements are made to the grasping part and the first cushion.

[0025] refer to Figure 5-6 , the gripping plate 18 and the wedge portion 19 are in sliding contact through a stepped contact surface 36, the top of the stepped contact surface 36 is provided with a second airbag 37, and the bottom of the second airbag 37 communicates with the casing 11 through a connecting hole 38, A fourth spring 39 is provided at the bottom of the stepped contact surface 36 . The third cushion 34 is provided with a cavity 40 , and the top of the cavity 40 is provided with a first elastic piece 41 , and the top of the second airbag 37 communicates with the cavity 40 . In the process of grabbing the circuit board, after the compressed air is fed into the air pipe 8, the compressed air enters the second air bag 37 through the connecting hole 38, so that the grabbing plate 18 is separated from the wedge-shaped part 19, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com