Waste tire dicing device

A waste tire and dicing technology, applied in recycling technology, plastic recycling, etc., can solve the problems of uneven rubber blocks and manual collection of rubber blocks, avoiding uneven size, realizing automatic collection, and good cutting effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

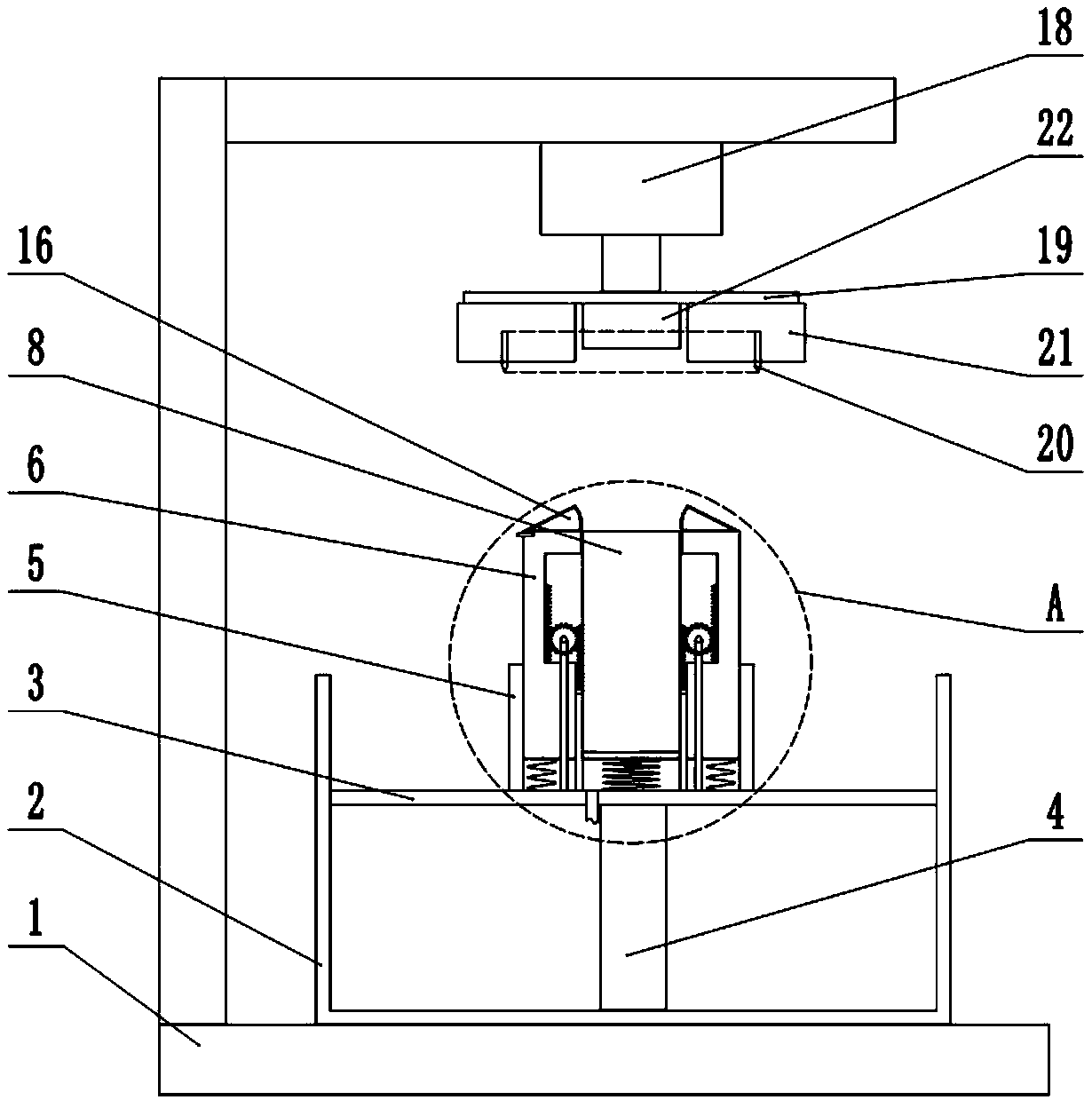

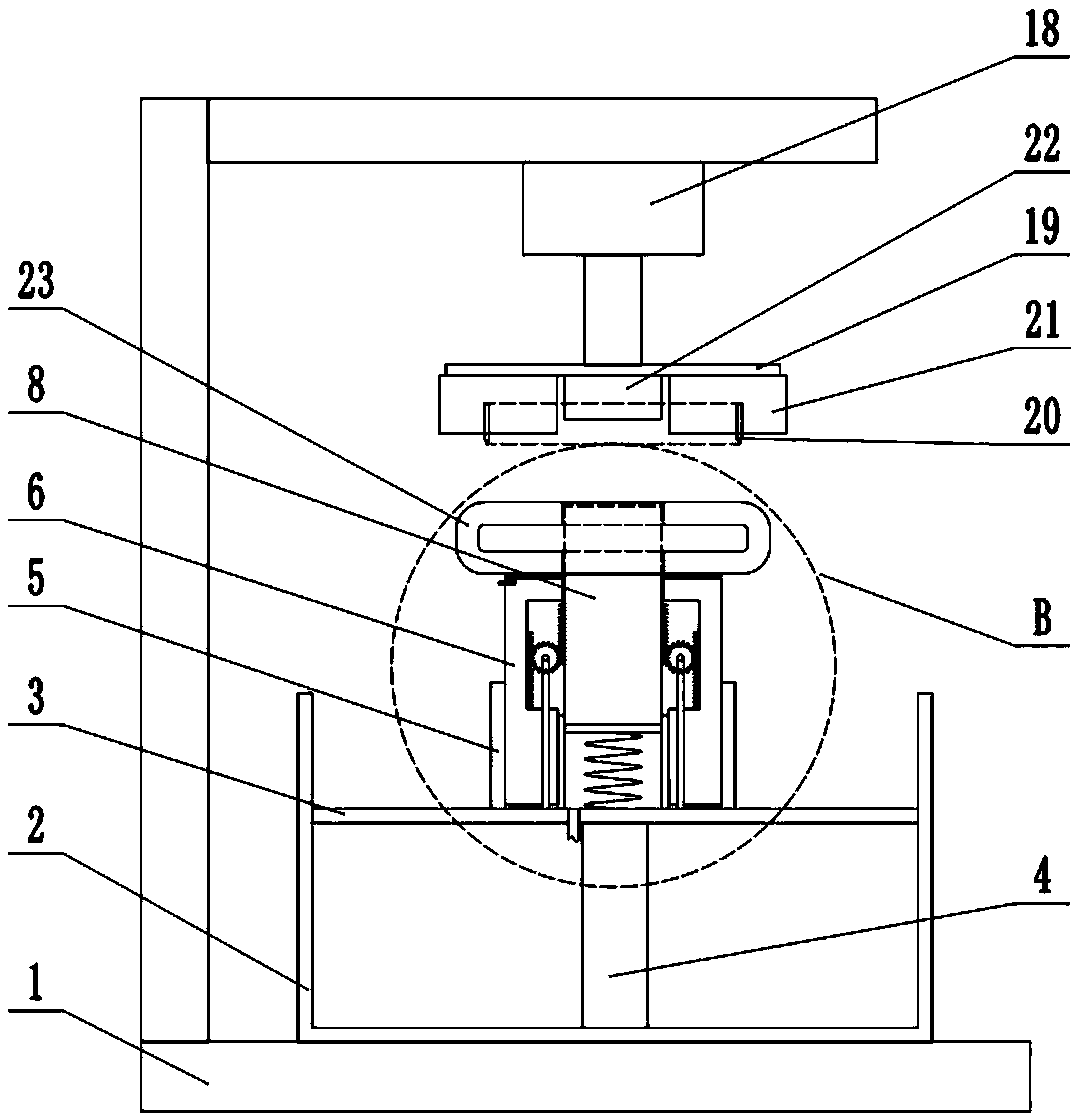

[0026] Basic as attached figure 1 , figure 2 Shown: a waste tire 23 cutting device, including a frame 1, a workbench, a cutting unit and a collection box 2, a bracket 3 is welded in the collection box 2, and a support column 4 is welded between the lower end of the bracket 3 and the bottom of the collection box 2, The workbench is fixed on the support 3.

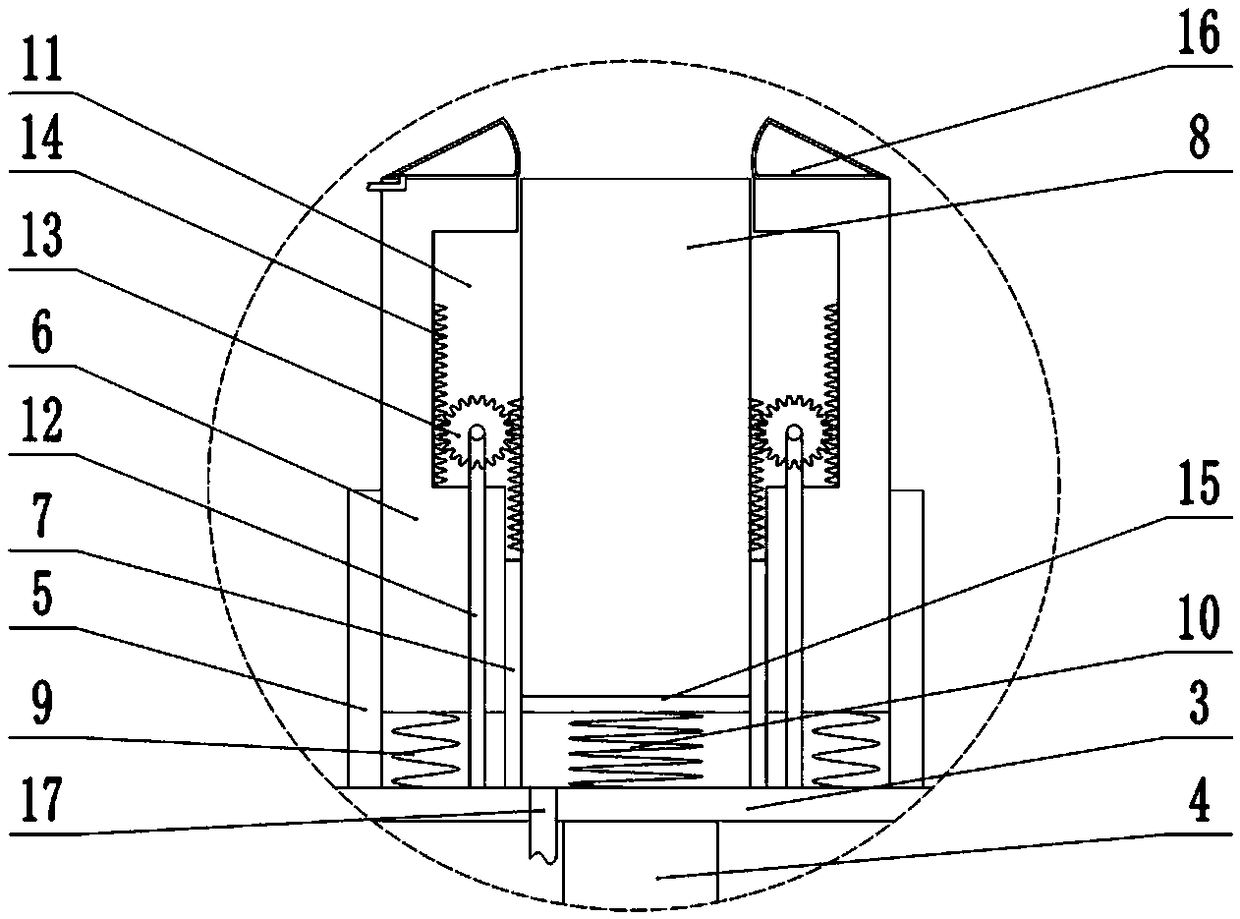

[0027] combine image 3 , Figure 4 , Figure 5 As shown, the workbench includes a central column 8, a sealed cylinder 7, a placement platform 6 and an outer ring 5, the outer ring 5 is fixed on the bracket 3 by bolts, the placement platform 6 is slidably connected in the outer ring 5, and the bottom of the placement platform 6 is connected to the bracket 3 Four compression springs 9 are fixed between them, and the four compression springs 9 are evenly distributed in the circumferential direction; the center of the placing table 6 is provided with a cavity for accommodating the sealing cylinder 7 and the central column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com