3D printing device and method for printing photosensitive materials

A technology of 3D printing and photosensitive materials, which is applied in the field of 3D printing equipment for printing photosensitive materials, can solve the problems of affecting the printing effect, the color is not pure enough, and the objects cannot be printed, and achieves the effect of ingenious design, strong creativity and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

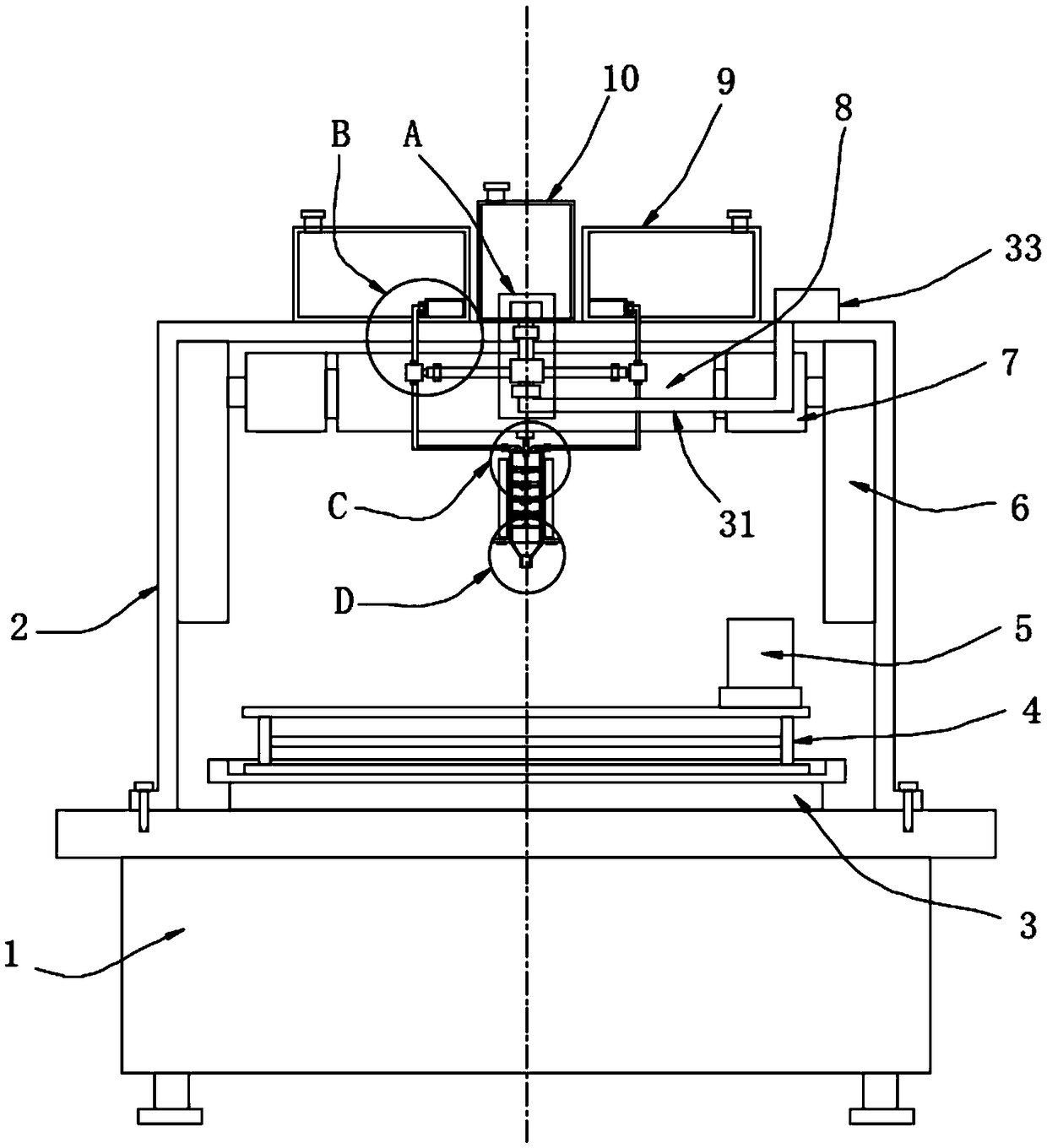

[0038] refer to Figure 1-7 , a 3D printing device for printing photosensitive materials, including a device base 1 and a cover body 2 arranged on the top of the device base 1, and also includes a pipeline cleaning system, a pipeline drying system, a mixing system, a photocuring system and a controller , the controller is set in the equipment base 1;

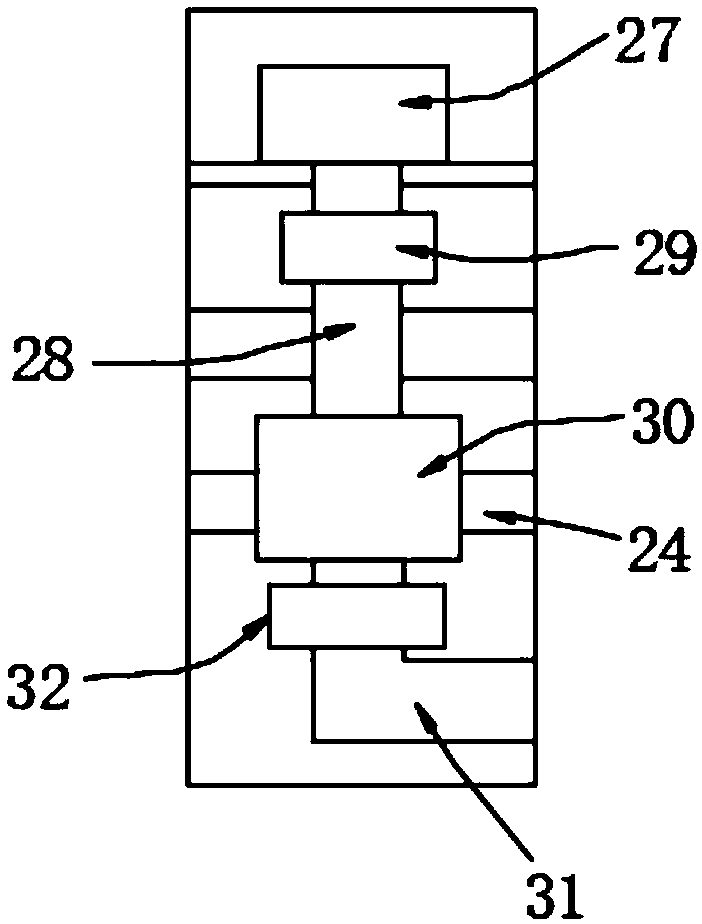

[0039] The pipeline cleaning system includes a water tank 10 and a water pump 27, the water tank 10 is installed in the middle of the top of the cover body 2, and the water pump 27 is installed in the inner bottom of the water tank 10;

[0040] The pipeline drying system comprises a hot-blast fan 33 and a hot-blast duct 31; the hot-blast fan 33 is arranged on the top of the cover body 2, and the hot-blast duct 31 is connected with the outlet end of the hot-blast fan 33;

[0041] The mixing system comprises a mixing tank 13, a rotating shaft 18 arranged on the inside of the mixing tank 13, a stirring blade 19 and an electric hea...

Embodiment 2

[0060] In this embodiment, the overall structure is the same as the first embodiment, the difference is that the lower end of the rotating shaft 18 runs through the circular plate 152 and is connected to the output shaft of the drive motor at the bottom of the circular plate 152, and the drive motor adopts a model of 60BL100B30- IP68 waterproof motor, through the setting of the motor, the stirring can be controlled electrically, the stirring efficiency is high, and the color mixing effect of the pigment is better.

[0061] Compared with the prior art, the beneficial effect of the present invention is: when printing, add the photosensitive resin of corresponding color according to the required color, wherein, when white is required, close the first electromagnetic valve 25 of other three colors, when When colors other than these four are required, since cyan, magenta, and yellow are the three primary colors of the color material, other colors can be obtained by adjusting the amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com