An aluminum alloy side wall structure and an automobile

A technology of aluminum alloy and aluminum alloy materials, applied in the direction of upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problems of poor strength, rigidity, not easy to bend, low material strength, etc., to ensure strength and rigidity, ensure Safe structure and good lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] This embodiment provides an aluminum alloy side wall structure and an automobile, and its specific structure is described below.

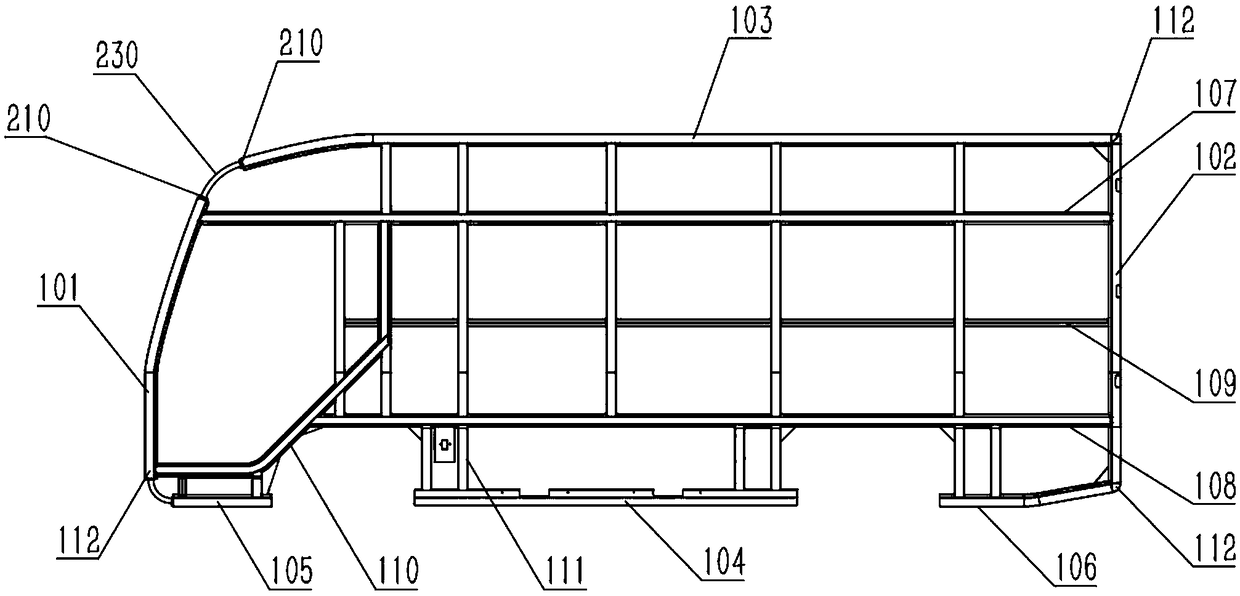

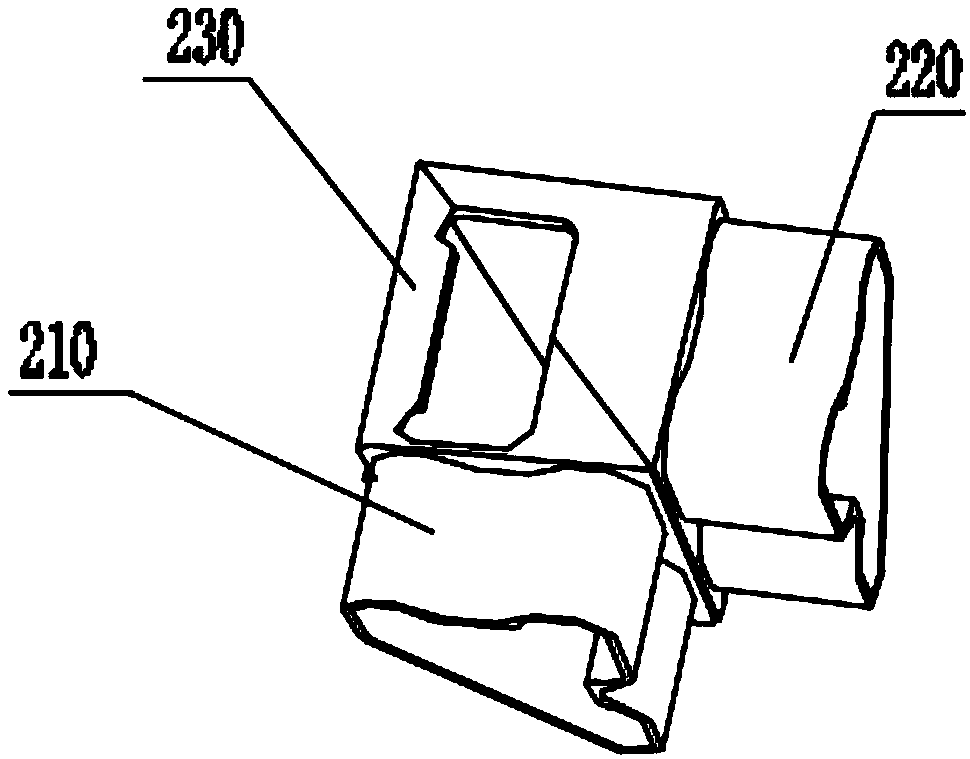

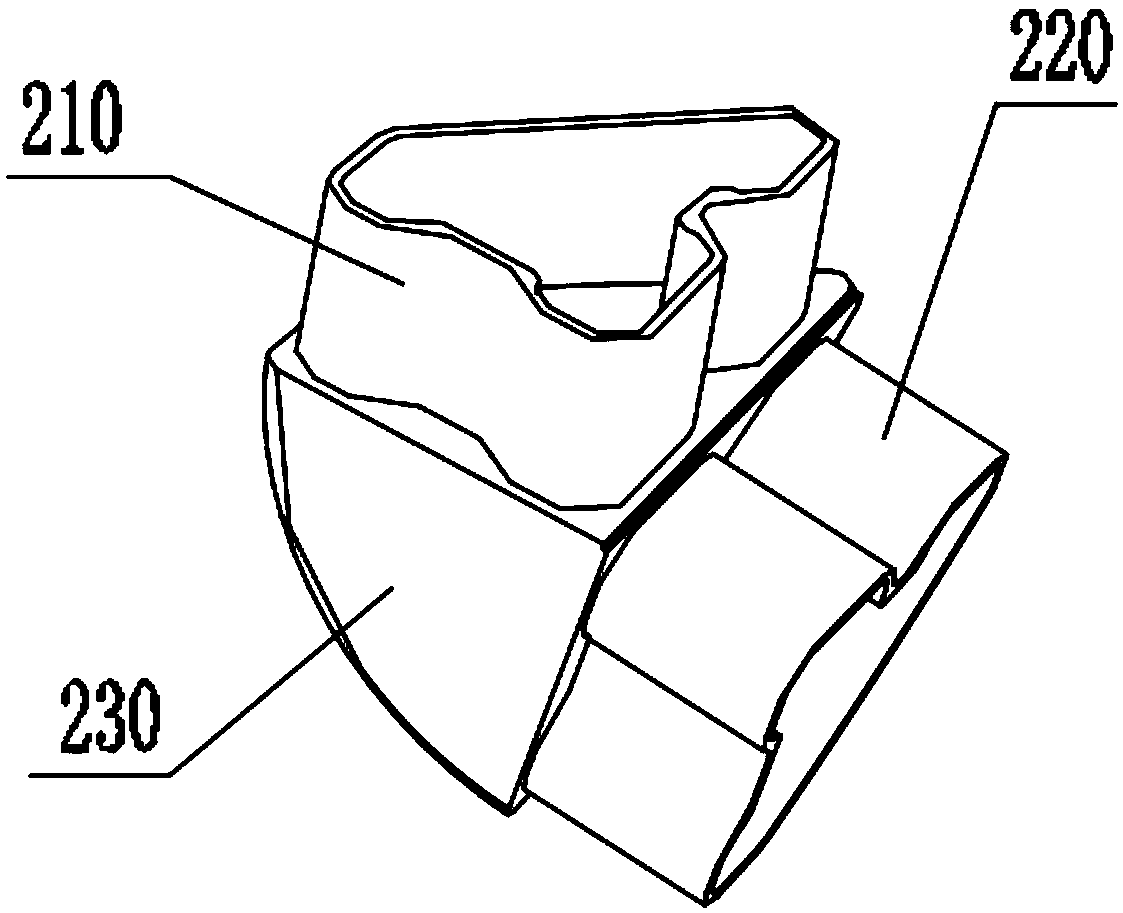

[0036] Please refer to figure 1 , in this embodiment, the aluminum alloy side wall structure includes an outer frame upper side beam 103, an outer frame A-pillar 101, an outer frame C-pillar 102, an outer frame lower middle side beam 104, an outer frame lower front side beam 105, an outer frame lower rear side A beam 106 , an upper beam 107 , a lower beam 108 , a middle beam 109 , a door beam 110 , a plurality of uprights 111 and an insertion joint 112 . A plurality of columns 111 and upper beam 107, lower beam 108, middle beam 109, door slanting beam 110, outer frame upper side beam 103, outer frame lower middle side beam 104, outer frame lower front side beam 105, outer frame lower rear side beam 106 Dock connection. The intersection points of the upper beam 107 and the ends of the outer frame A-pillar 101 and the outer frame C-pillar 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com