Steel-wire-rope-driven folding joint template for assembly-type building and construction method thereof

A wire rope and prefabricated technology, which is applied to the foldable seam formwork driven by steel wire rope for prefabricated buildings and the construction field, which can solve the problems of low formwork strength, unstable fixation, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

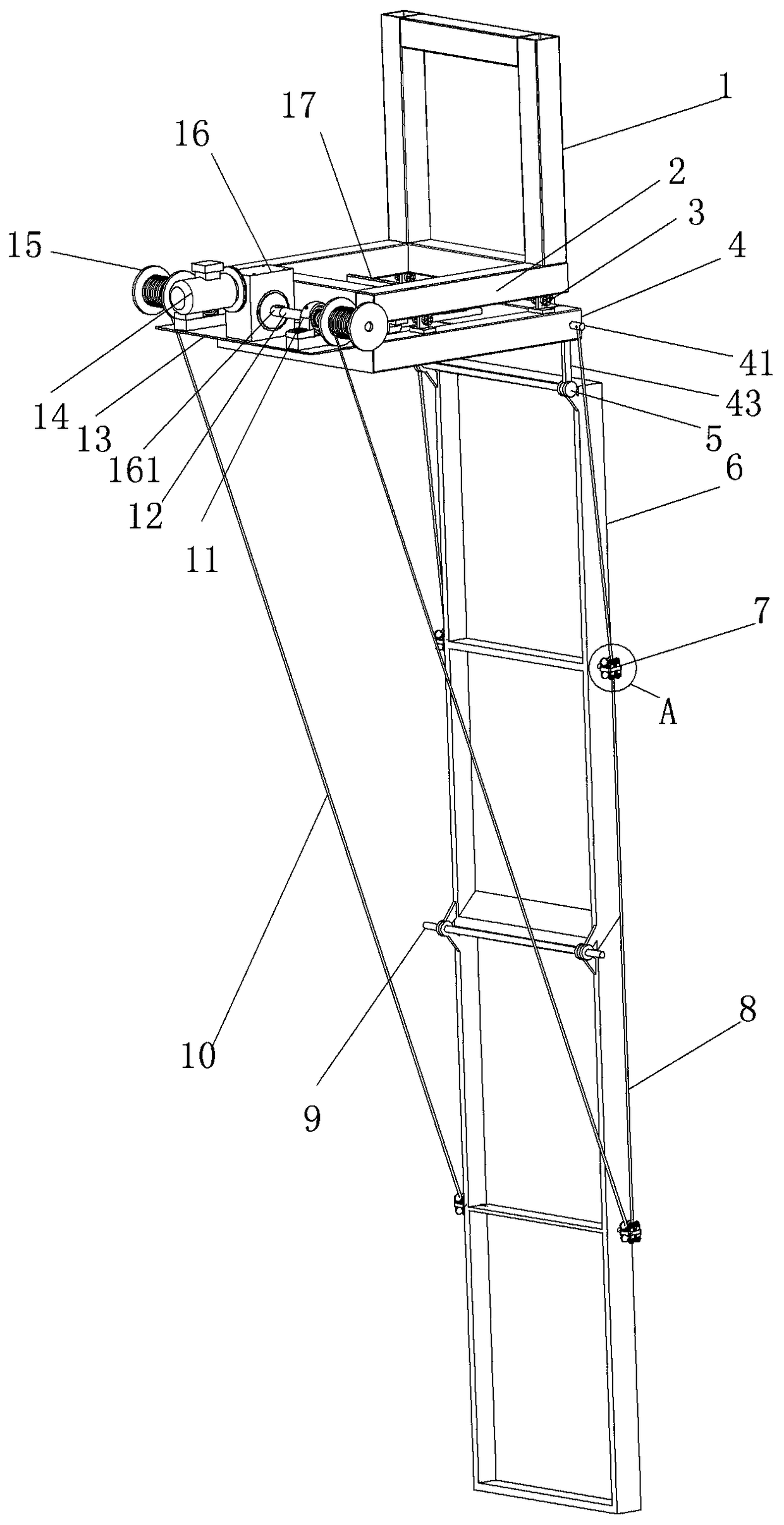

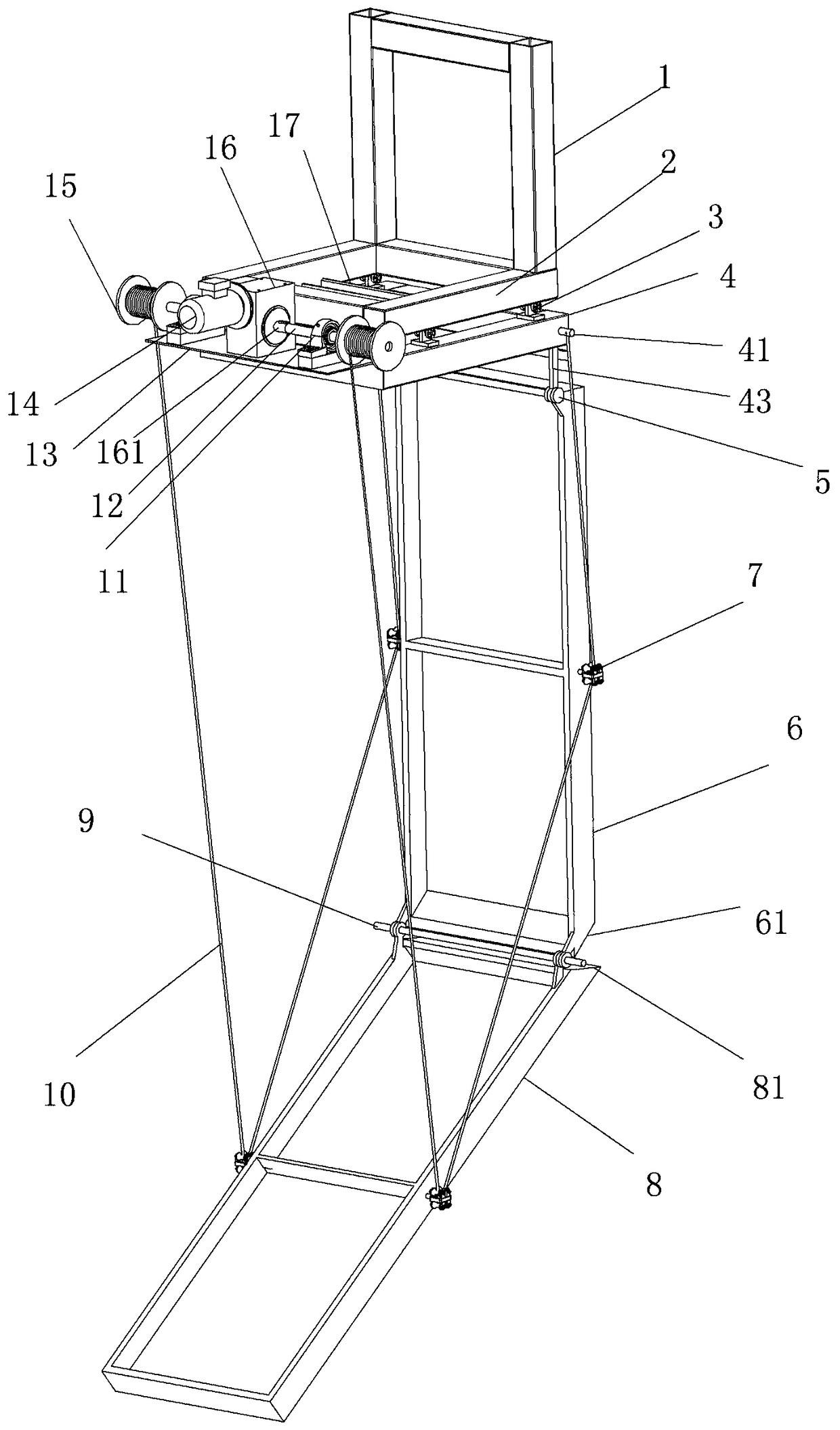

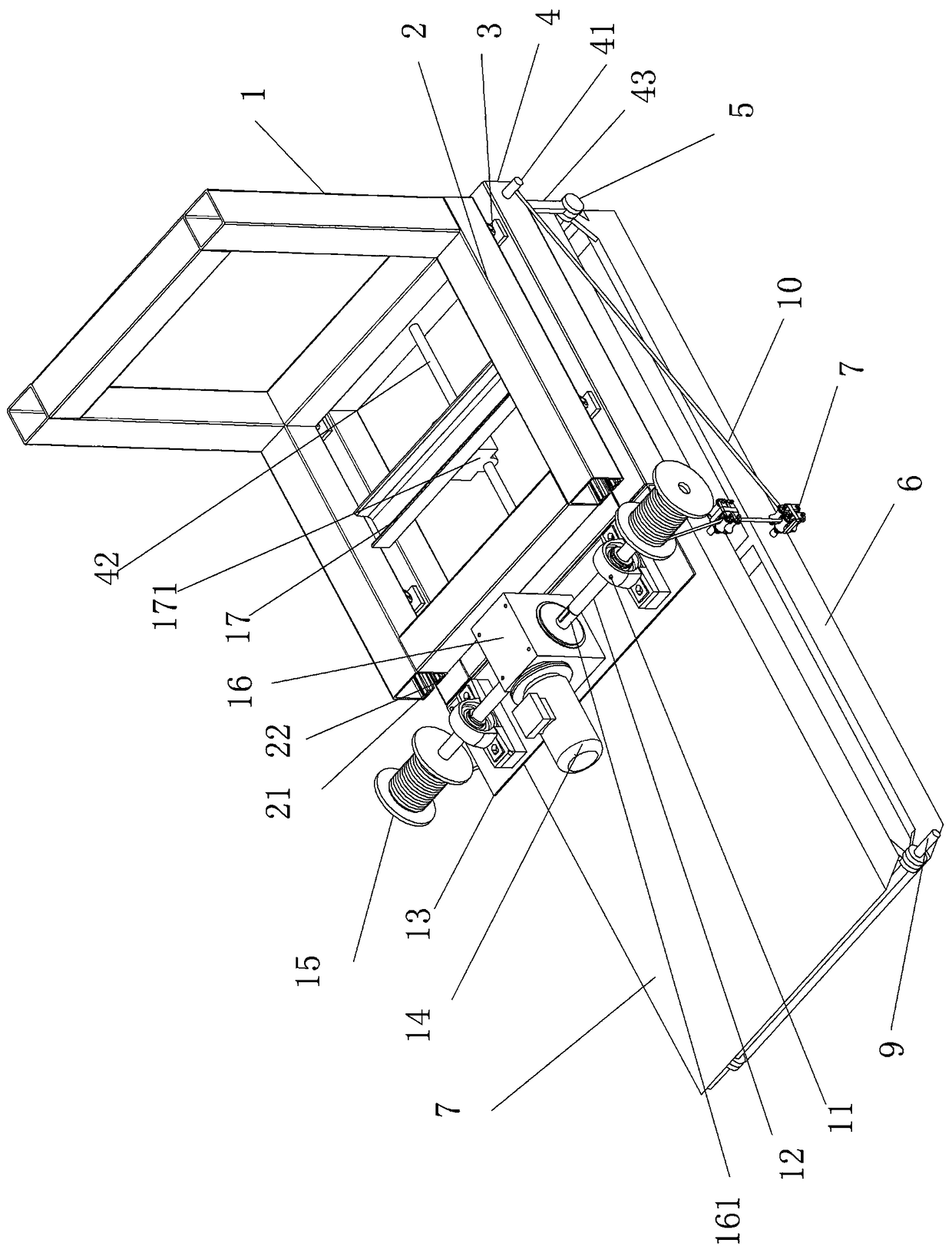

[0035] see Figure 1-9 , a foldable seam formwork driven by wire ropes for prefabricated buildings, the foldable formwork includes a support component, a drive component, and a foldable formwork;

[0036] The support assembly includes a fixed frame and a sliding frame. The sliding frame is installed under the fixed frame through a pulley assembly. The fixed frame includes a horizontal frame and a vertical frame. The vertical frame is installed on the truss of the temporary construction platform through U-shaped mounting bolts and positioning holes. Above, the side structure of the horizontal frame is two relatively parallel square steel pipes. The bottom surface of each square steel pipe is provided with a slit along the length direction of the square steel pipe. a pulley track for use with the pulley assembly;

[0037] Each of the pulley assemblies includes a pulley frame and a pulley. The pulley frame includes a flat plate and a connecting plate fixed vertically to each other...

Embodiment example 2

[0047] see Figure 1-9 , a method of applying the foldable joint formwork described in Implementation Case 1 to carry out the joint construction method of a prefabricated building wall, the specific steps are as follows:

[0048] ① Use the folded templates in pairs, and install them symmetrically on the trusses of the temporary construction platform on both sides of the joints between the prefabricated walls in the prefabricated building through the fixing frame;

[0049] ②The hoisting motor in the driving device drives the wire rope drum to rotate, and the rotating wire rope drum releases the wire rope coiled on the wire rope drum, and the upper formwork and the lower formwork are gradually unfolded downward under the action of their own gravity until When the upper formwork and the lower formwork are fully deployed on the same plane and the steel wire rope is in a slack state, stop releasing the steel wire rope;

[0050] ③The horizontal drive motor on the horizontal frame o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com