500 kV composite cross arm single-circuit strain tower

A composite material and single-circuit technology, applied to towers, building types, buildings, etc., can solve the problems of not fully utilizing the insulation properties of composite materials and reducing the size of the tower head, so as to reduce the probability of wind deflection flashover accidents and simplify the structure , Improve the effect of safe operation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the drawings and specific embodiments.

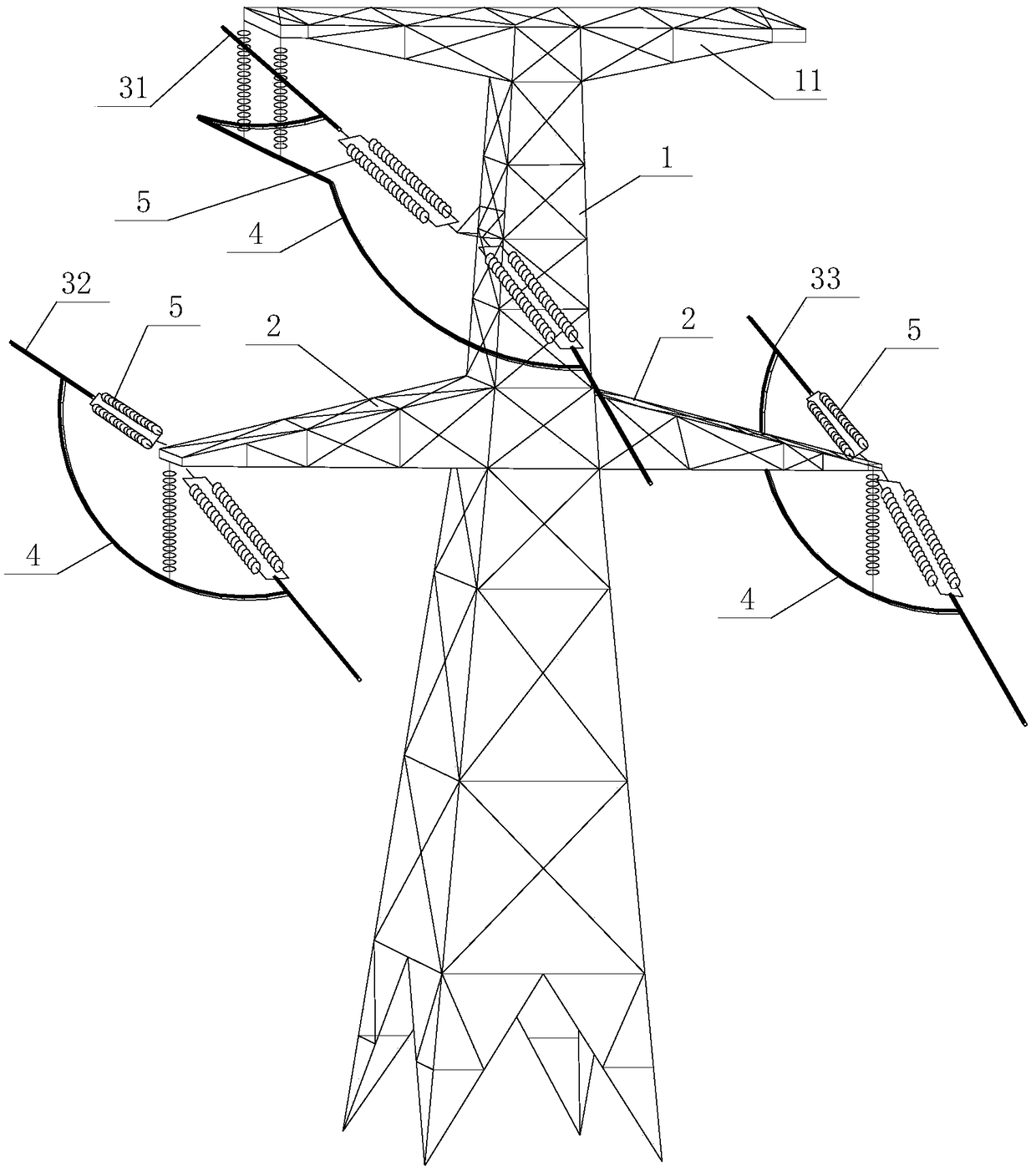

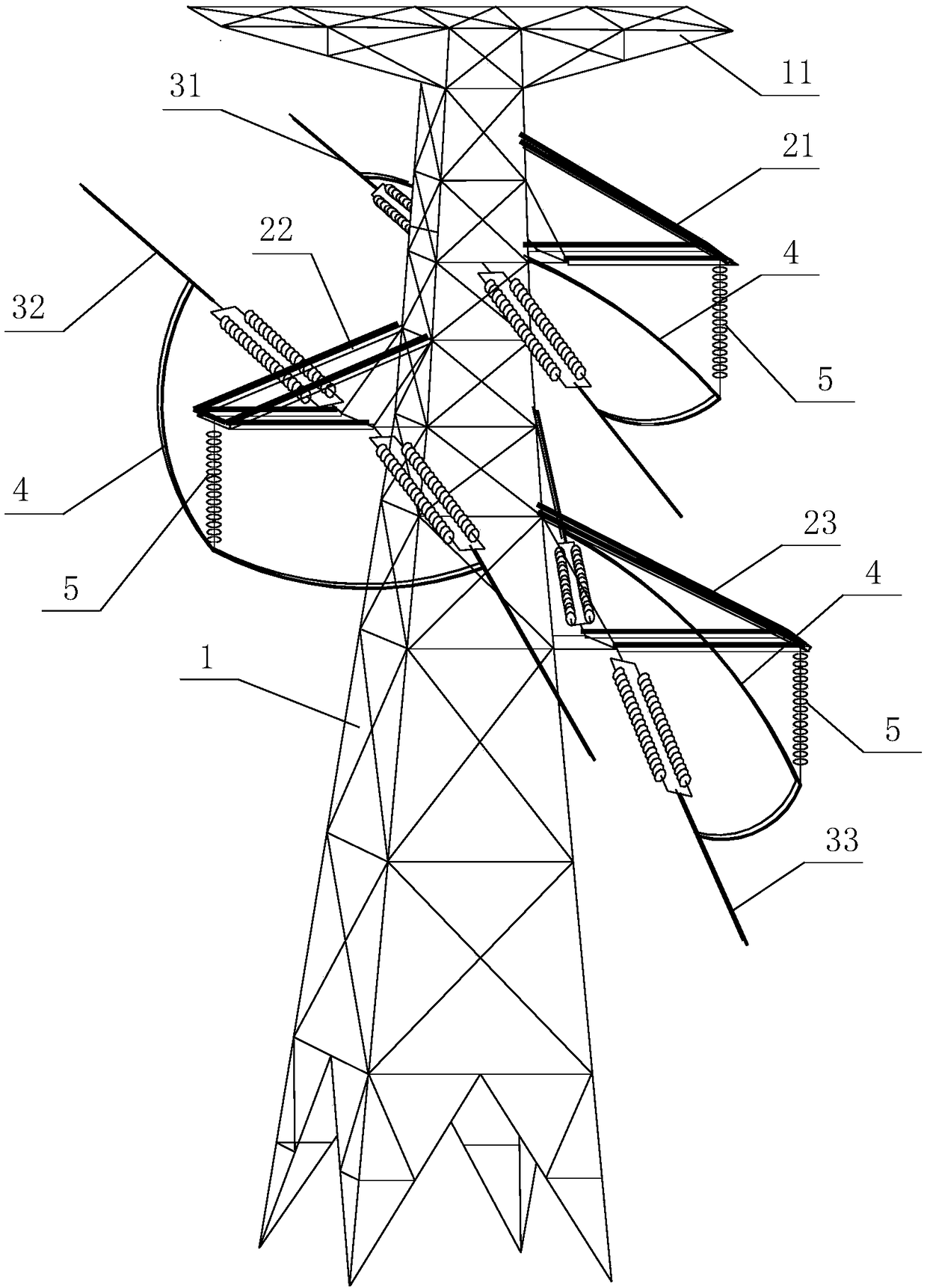

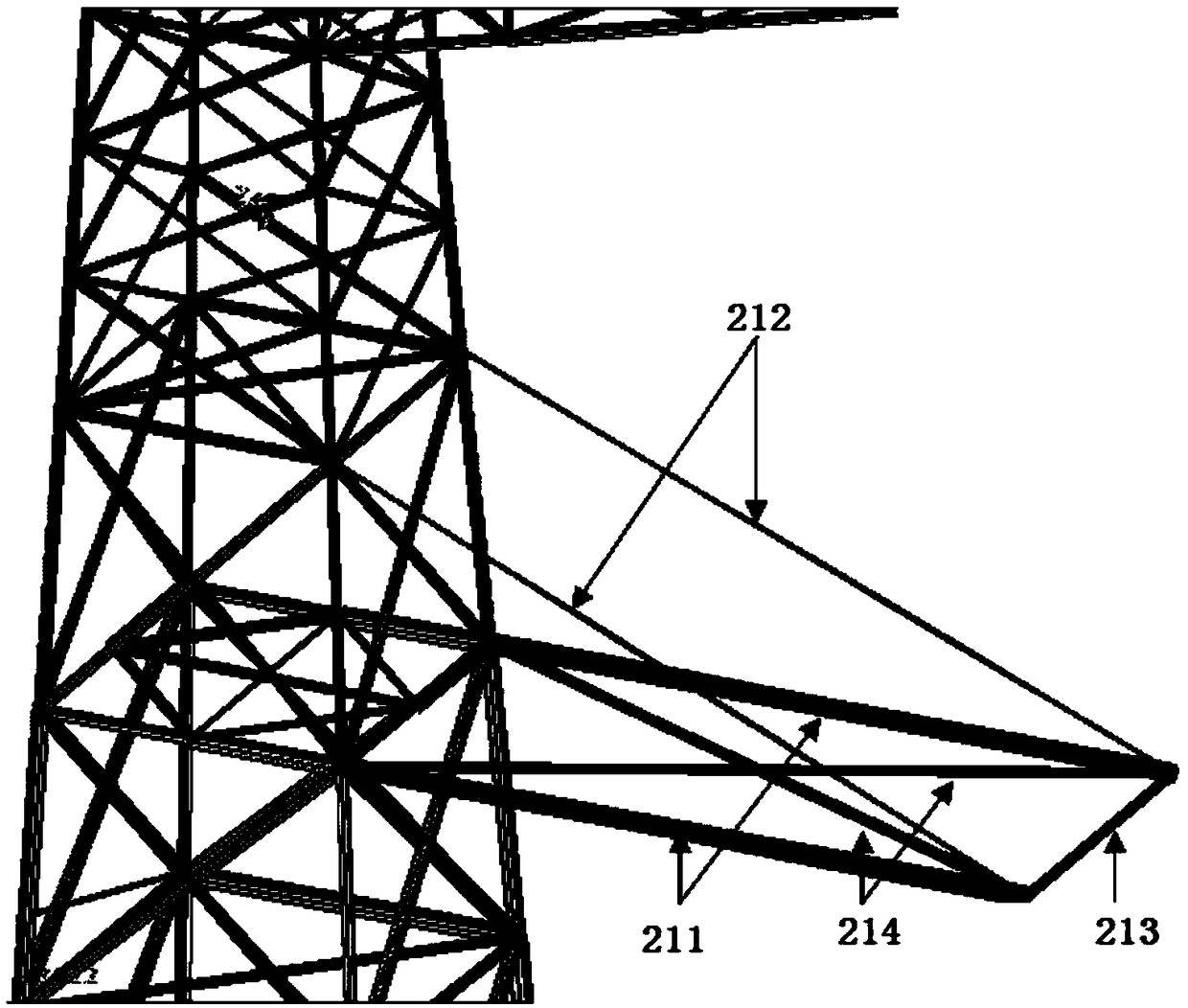

[0030] Such as figure 1 As shown, in the existing single-circuit strain tower, the upper phase conductor 31 and the corresponding jumper 4 are suspended on the tower body 1 through the insulator string 5, and the middle phase conductor 32, the lower phase conductor 33 and the corresponding jumper 4 are passed through the insulator. The string 5 is hung on the cross arm 2 at the same level, and the cross arm 2 and the tower body 1 are made of angle steel. Since the middle phase conductor 32 and the lower phase conductor 33 are suspended at the same height, the corridor width is required to be wider, and the space along the line is larger, which increases the felling of trees; and the cross arm 2 and the tower body 1 are made of angle steel to meet the insulation requirements , The required insulator string 5 is longer, which increases the distance between the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com