Water-cooled motor shell detection device

A detection device and a technology of water-cooled motors, which are applied in the direction of detecting the appearance of fluid at the leakage point and using liquid/vacuum to measure the liquid tightness, etc., can solve the problem of manual operation of the air guide pipeline, increased manual workload, and air guide Pipeline shaking and other problems, to achieve the effect of reducing scrap rate, convenient operation, and reducing error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

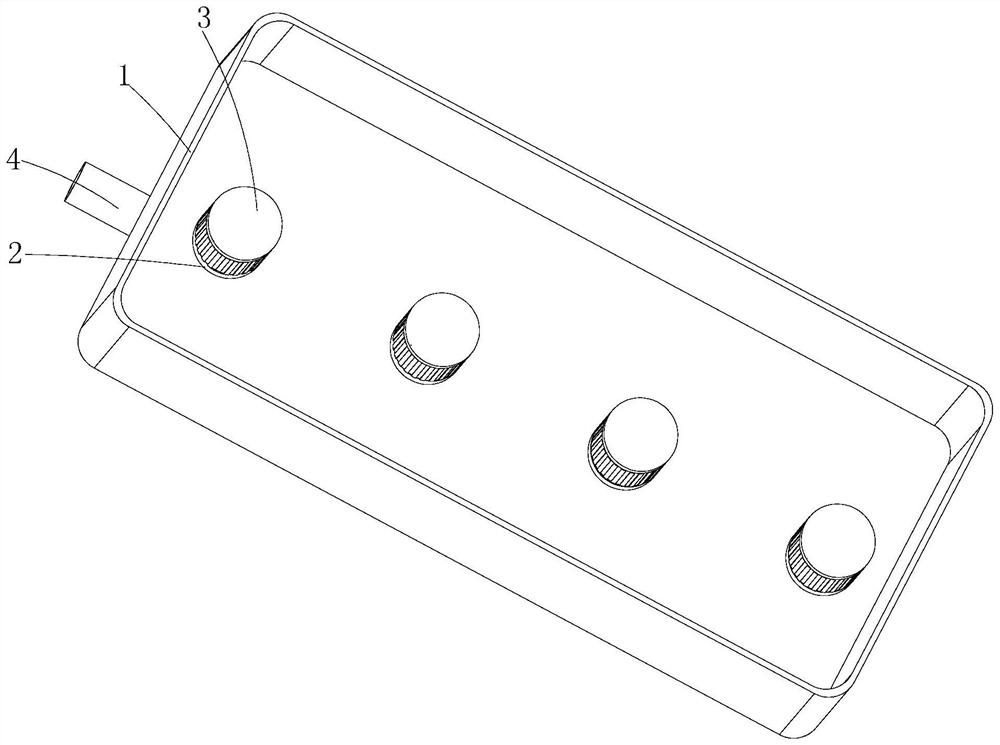

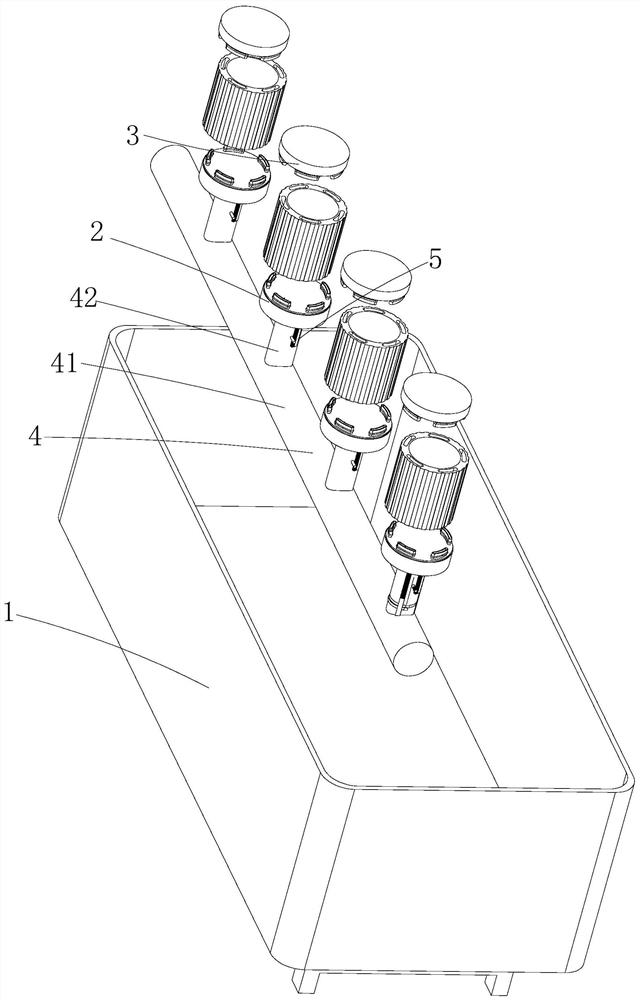

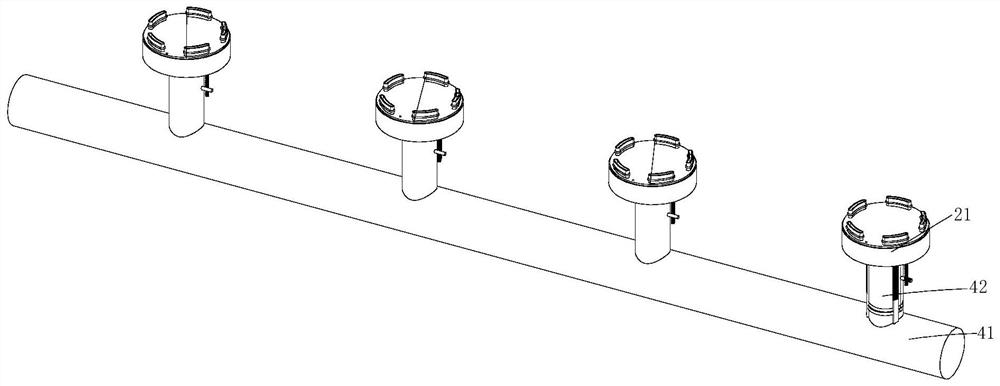

[0034] As shown in Fig. 1-10, a water-cooled motor housing detection device includes a detection box 1, a first blocking part 2, a second blocking part 3, an air guide pipe 4 and an opening and closing structure 5, wherein the detection box 1 is a metal box, and detection liquid is packed in this detection case 1, and described detection liquid can be water; Described air guiding pipeline 4 comprises main pipe 41 and a plurality of branch pipes 42, and described main pipe 41 is a metal pipeline, and this main pipe 41 Buried at the bottom of the detection box 1, the branch pipe 42 is also a metal pipe. The bottom is vertical; after the gas passes into the main pipe 41 , it wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com