Clean room affected area detection method

A detection method and clean room technology, applied in separation methods, chemical instruments and methods, measuring devices, etc., can solve problems such as inaccurate monitoring, high cost, and limited pipeline length, so as to improve detection efficiency and reduce monitoring costs , to achieve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

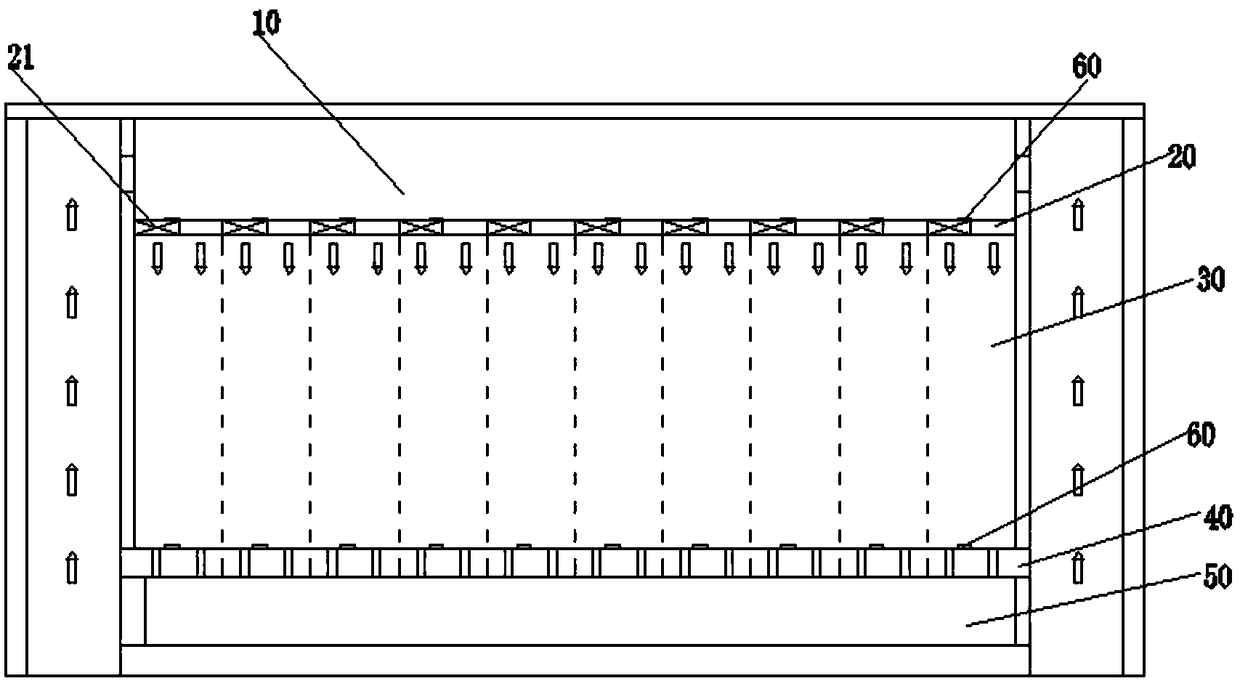

[0031] see figure 1 , as shown in the legend, a method for detecting the damaged area in a clean room, including the following steps:

[0032] (1) Provide a clean room. The clean room includes air supply space 10, ceiling 20, clean space 30, elevated floor 40 and air return space 50 arranged in sequence from top to bottom. The ceiling 20 is divided into a plurality of air supply areas, and the elevated The floor 40 is divided into a plurality of exhaust areas, the air supply area and the exhaust area are arranged one by one up and down, and a cylindrical space is formed between the corresponding two. The clean room also includes a detection mechanism corresponding to the cylindrical space, Each detection mechanism includes a corrosion test piece 60 in contact with the corrosive gas flowing through its corresponding cylindrical space and a detection unit for detecting the electrical performance parameters of the corrosion test piece 60;

[0033] (2) Monitor the electrical perf...

Embodiment 2

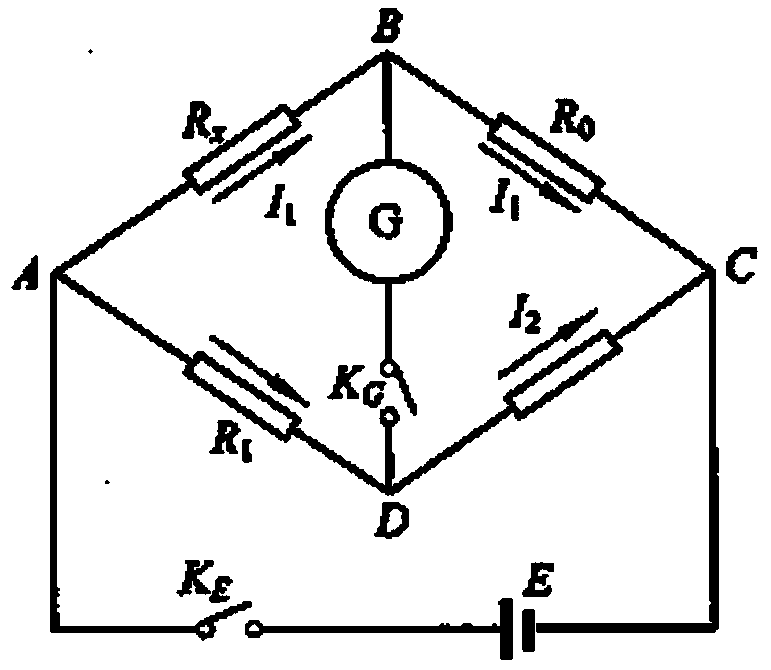

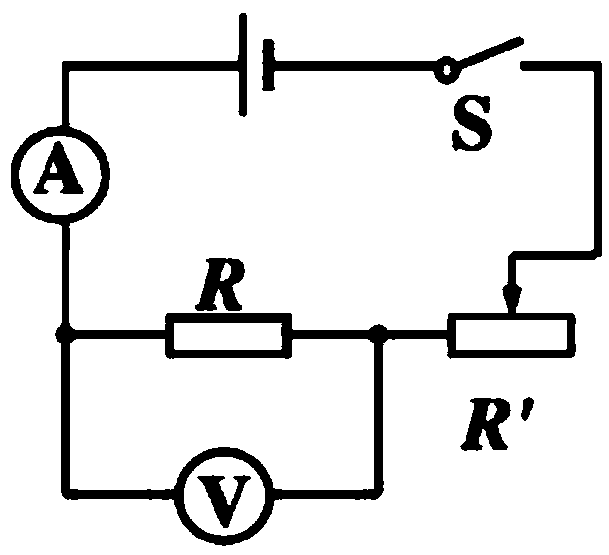

[0047] The rest is the same as the first embodiment, except that the corrosion test piece 60 and the detection unit form a voltammetry resistance circuit, and the corrosion test piece 60 is used as the resistance to be measured in the voltammetry resistance circuit. principle such as image 3 shown.

[0048] Voltammetric resistance measurement is a common method of directly measuring the resistance to be measured by using an ammeter and a voltmeter. The resistance value is measured by using Ohm's law of a part of the circuit: R=U / I. Use an ammeter to measure the current passing through the unknown resistance at this voltage, and then calculate the resistance value of the unknown resistance, which can be roughly divided into two types, the ammeter is internally connected and the ammeter is externally connected. The so-called external internal connection means that the ammeter is connected outside the voltmeter. or inside, the specific steps are as follows:

[0049] (1) Adjust...

Embodiment 3

[0054] The rest are the same as any one of Embodiment 1 or 2, except that the detection unit is an ohmmeter or a multimeter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com