Water bucket for controlling liquid level height to be unchangeable and height control method thereof

A liquid level, liquid control technology, applied in liquid level control, non-electric variable control, control/regulation systems, etc., can solve problems such as affecting health, polluting food in buckets, and dropping spoons into buckets, etc. The effect of avoiding water short circuit and preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

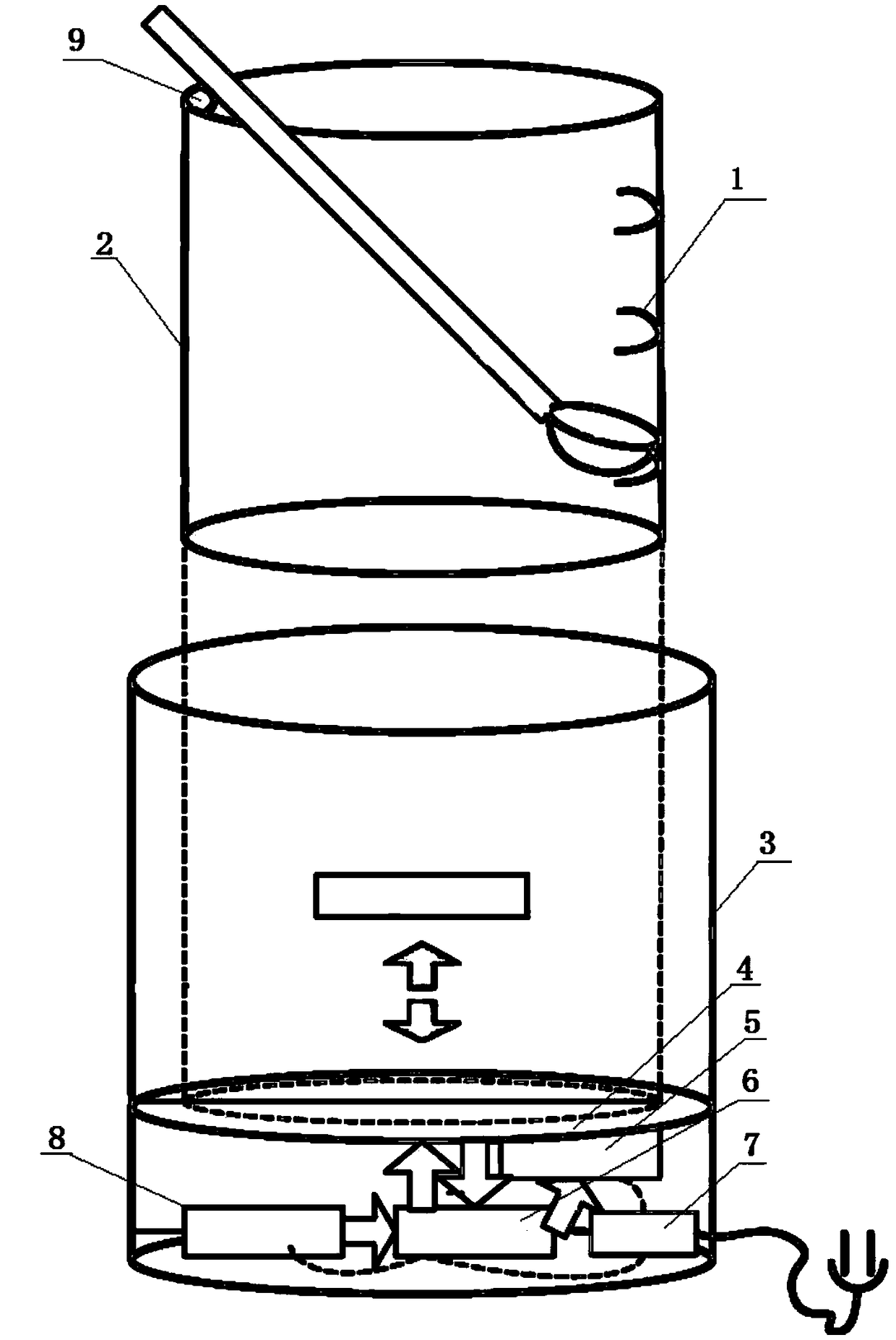

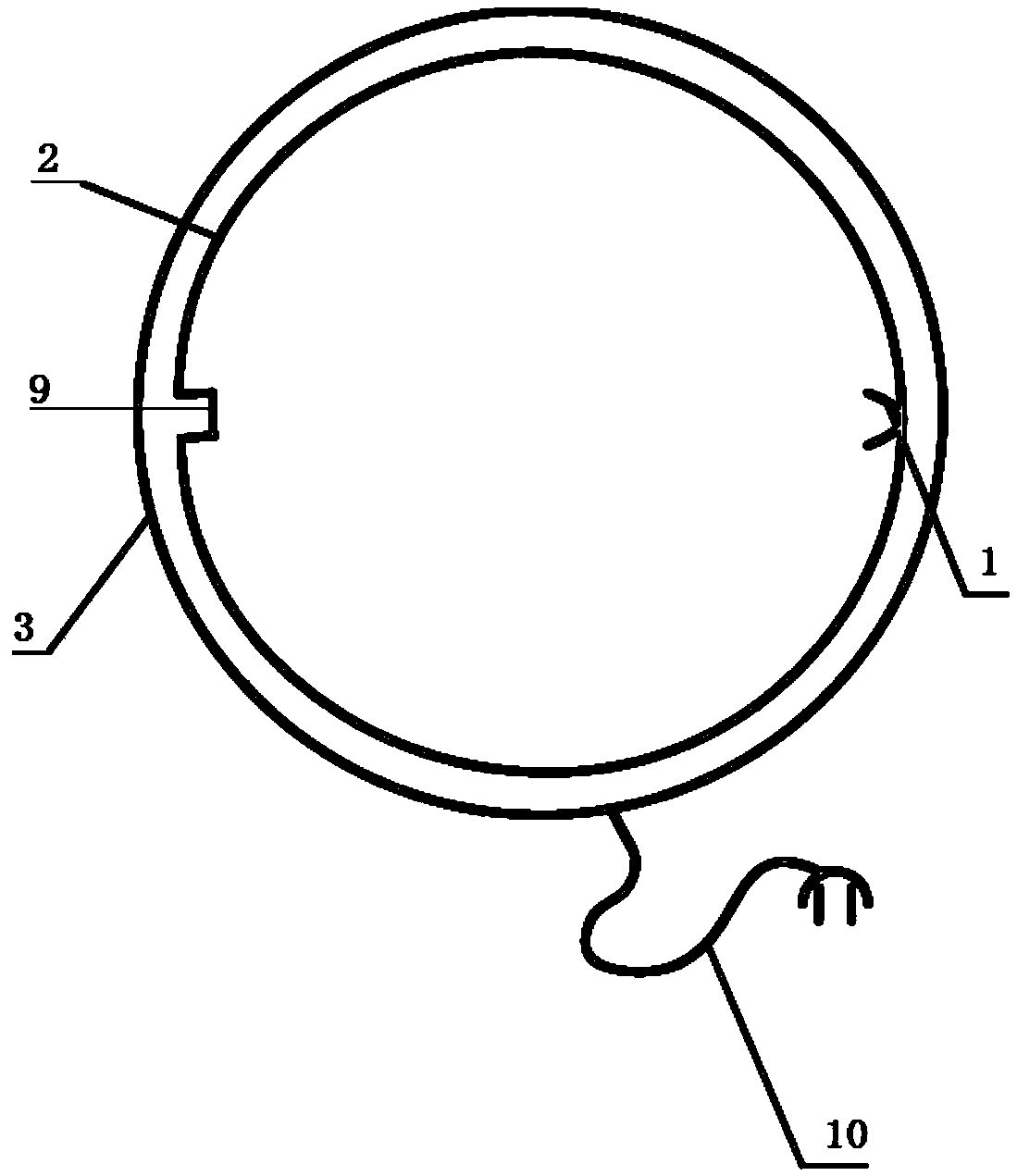

[0054] Example 2, such as Figure 2-4 As shown, the present embodiment is similar to the structure of a water bucket that controls the constant height of the liquid level in Embodiment 1, the difference is that:

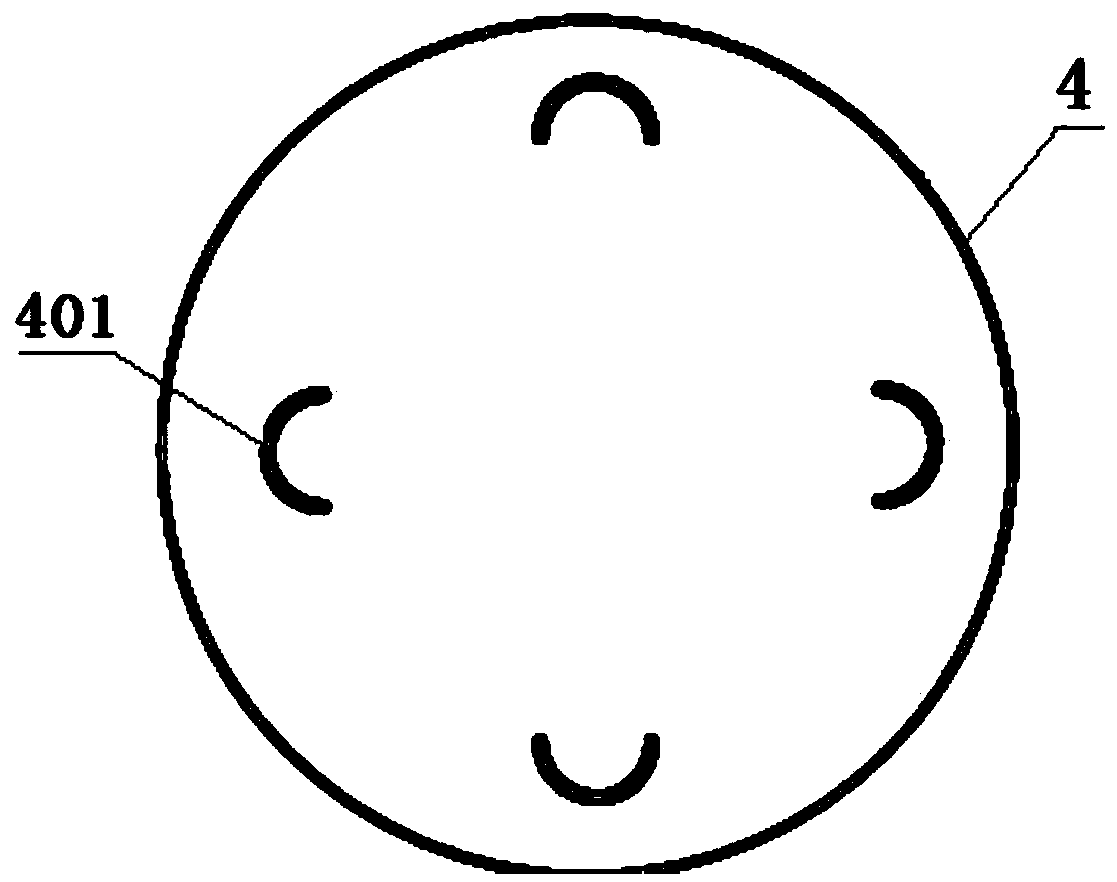

[0055] The outer surface of the liner 2 is evenly provided with a plurality of guide blocks, the guide blocks are provided with guide holes, the guide holes are provided with guide columns, and the lower end surfaces of the guide columns are fixedly connected with the bottom end surface of the inner cavity of the shell 3 . A spring is sheathed on the outer circular surface of the guide post, and the two ends of the spring are respectively in contact with the bottom end surfaces of the inner cavity of the inner tank support 4 and the outer shell 3 . Through the joint action of the spring and the guide column, the pressure on the pressure sensor and the electric push rod can be shared, so that the inner tank can rise more smoothly.

[0056] In the liquid level control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com