A gas-liquid mixing evaporation control device for combustion experiments

A gas-liquid mixing and control device technology, which is applied in the direction of using combustion for chemical analysis, using electric methods for temperature control, and auxiliary controllers with auxiliary heating devices. It can solve problems such as poor economy and achieve low production costs. Easy to promote and use, the effect of simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

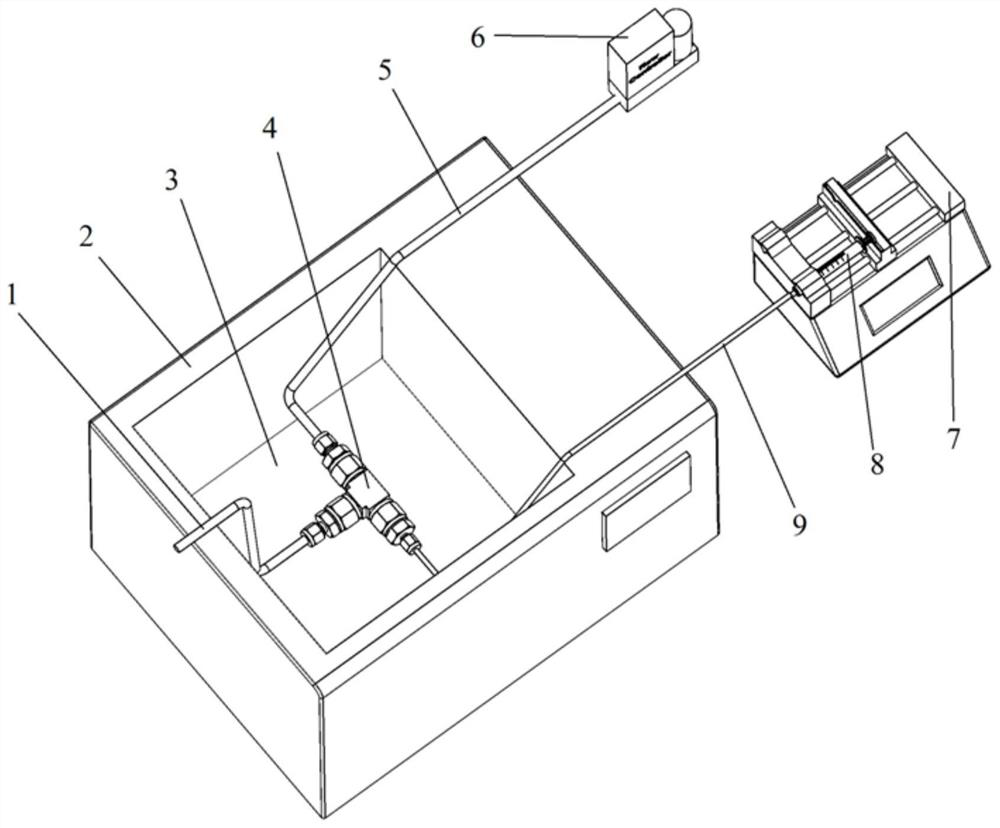

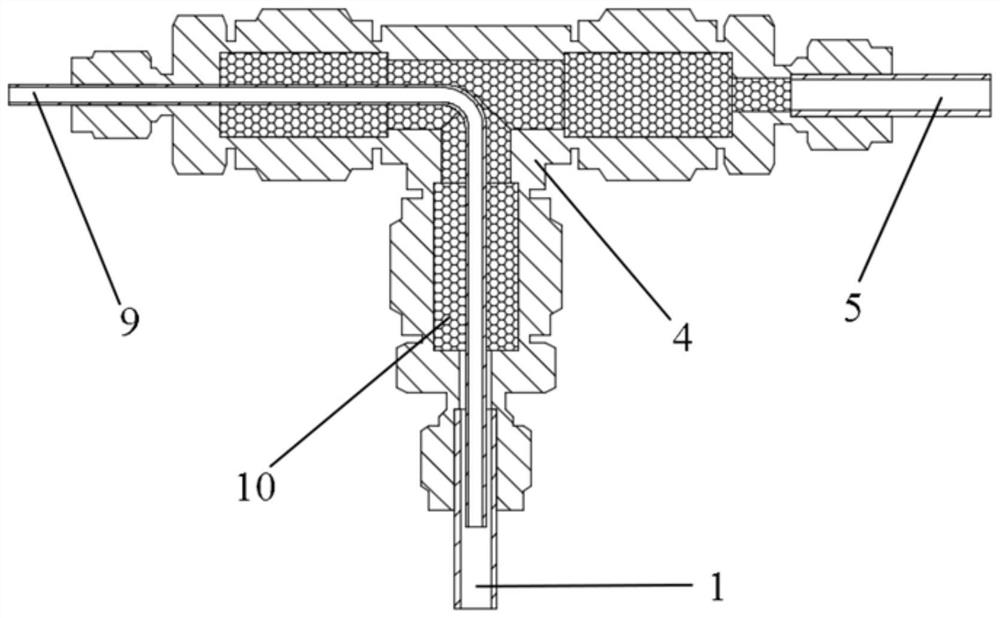

[0015] Such as figure 1 , figure 2 As shown, a gas-liquid mixing and evaporation control device for combustion experiments includes an oil bath heating and heat preservation mechanism, a three-way gas-liquid mixing mechanism 4, a gas delivery mechanism and a liquid delivery mechanism, and the oil bath heating and heat preservation mechanism includes an electronic constant temperature oil bath pot 2. The electronic constant temperature oil bath is filled with heat exchange medium 3, the three-way gas-liquid mixing mechanism is set in the electronic constant temperature oil bath, the gas delivery mechanism includes the gas delivery pipeline 5 and the gas mass flow controller 6, and the liquid delivery mechanism includes the liquid The delivery pipeline 9 and the liquid flow controller, one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com