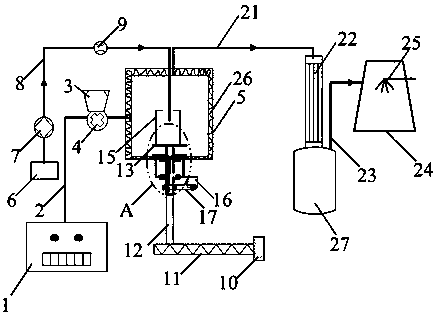

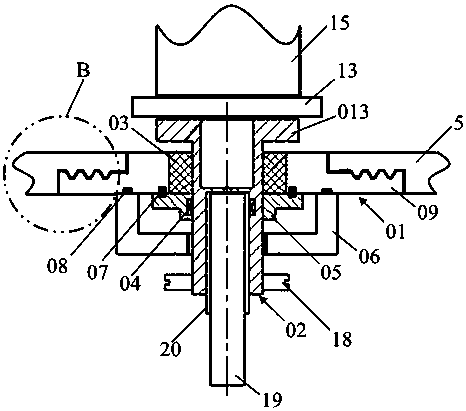

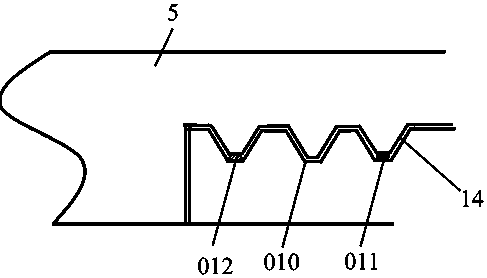

Semi-continuous automatic microwave denitrification device

A semi-continuous, microwave technology, applied in the fields of inorganic chemistry, rare earth metal compounds, chemical instruments and methods, etc., can solve the problems of entering and leaving the denitration container, gas, microwave leakage, and high airtightness requirements, and achieve the composition and particle size of the denitration product. The effect of uniform diameter, low nitrate content and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1: Put the denitrification container 15 into the tray 13 in the operation area, set the parameters such as feeding speed and microwave power, and the equipment will run automatically. The transmission mechanism transmits the denitrification container 15 to the resonant cavity 5, and continuously adds the uranyl nitrate solution into the denitrification container 15 through the metering pump 7, and automatically heats for 150 minutes. After the feeding is completed, continue heating, automatically control the temperature at 250°C for heating and denitrification for 10 minutes, and stop heating. After cooling for 30 minutes, the material is transported to the operation area through the transmission mechanism, and the denitrification product obtained is uranium trioxide, and the ratio of oxygen to uranium is 3.02:1.

Embodiment 2

[0064] Embodiment 2: Put the denitration container 15 into the tray 13 in the operation area, and add a gadolinium nitrate solution containing 150 g of gadolinium in a volume of about 500 mL into the denitration container 15 . Set the feeding speed, microwave power and other parameters, the equipment runs automatically, the transmission mechanism transfers the denitrification container 15 to the resonance cavity 5, starts heating, and stops heating after 60 minutes of heating. After cooling for 30 minutes, the material is transported to the operation area through the transmission mechanism, and the denitrification product is digadolinium trioxide, and the ratio of oxygen to gadolinium is 1.5:1.

[0065] The invention realizes semi-continuous production, automation with remote operation function, and almost no tail gas discharge; the denitrification container enters and exits the resonant cavity vertically, and the translation structure and lifting structure operate smoothly; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com