A structural design method of coarse-grained saline soil embankment based on uplift deformation control

A deformation control and structural design technology, applied in design optimization/simulation, geometric CAD, special data processing applications, etc., can solve problems such as the lack of a method for determining the deformation of the embankment top surface elevation and the lack of theoretical basis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

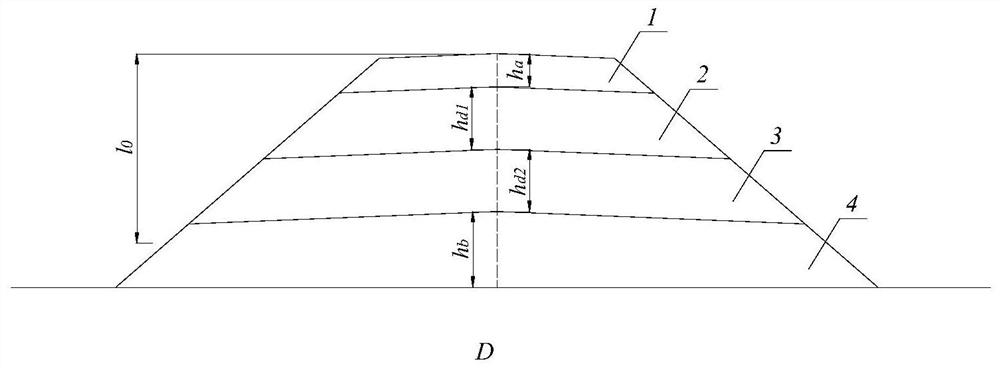

[0049] refer to figure 1 , A high-speed railway embankment is built on a saline soil foundation D. The embankment is filled with a height of 5.3m, a top width of 7.8m, and a slope ratio of 1:1.5. The design plans to use coarse-grained saline soil for filling.

[0050] In order to avoid the bulge deformation of the above-mentioned high-speed railway embankment, the method of the present invention is adopted to determine the structure of the coarse-grained saline soil embankment, and the concrete steps are as follows:

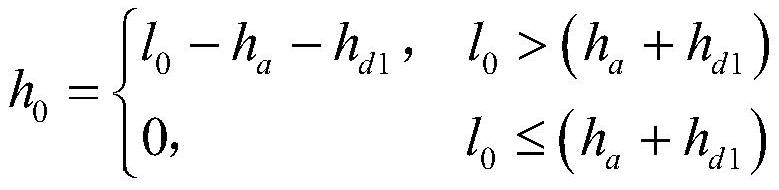

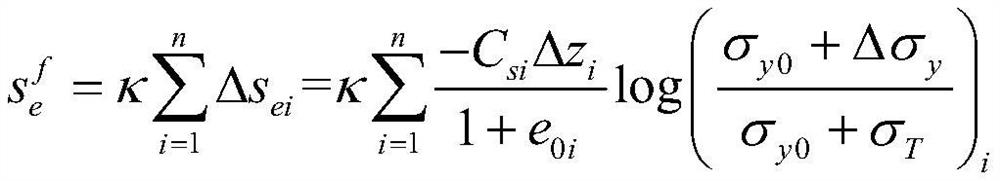

[0051] (1) According to the deformation control requirements of the high-speed railway, determine the allowable uplift of the top surface of the embankment [s e f ] is 4.0mm.

[0052] (2) Preliminarily determine the structure of the coarse-grained saline soil embankment, and the thickness h of the subgrade surface a is 0.4m, and is filled with coarse-grained non-saline soil; the thickness of the structural layer on the bottom of the subgrade is h d1 is 0.5m, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com