Production method of sauted pericarpium zanthoxyli oil

A production method, the technology of fragrant pepper, applied in the direction of edible oil/fat, food science, application, etc., can solve the problems of insufficient numbness, increased health risks, and high peroxide value of oil, so as to shorten the shelf life, increase health risks, The effect of a long warranty period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

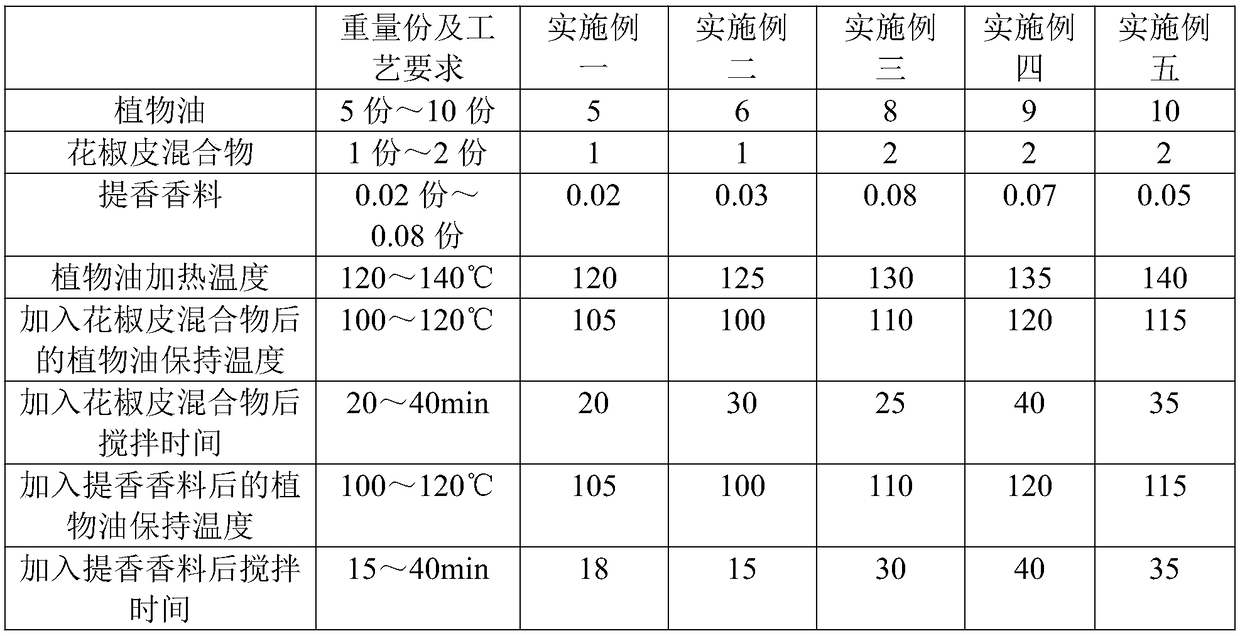

Examples

Embodiment 1

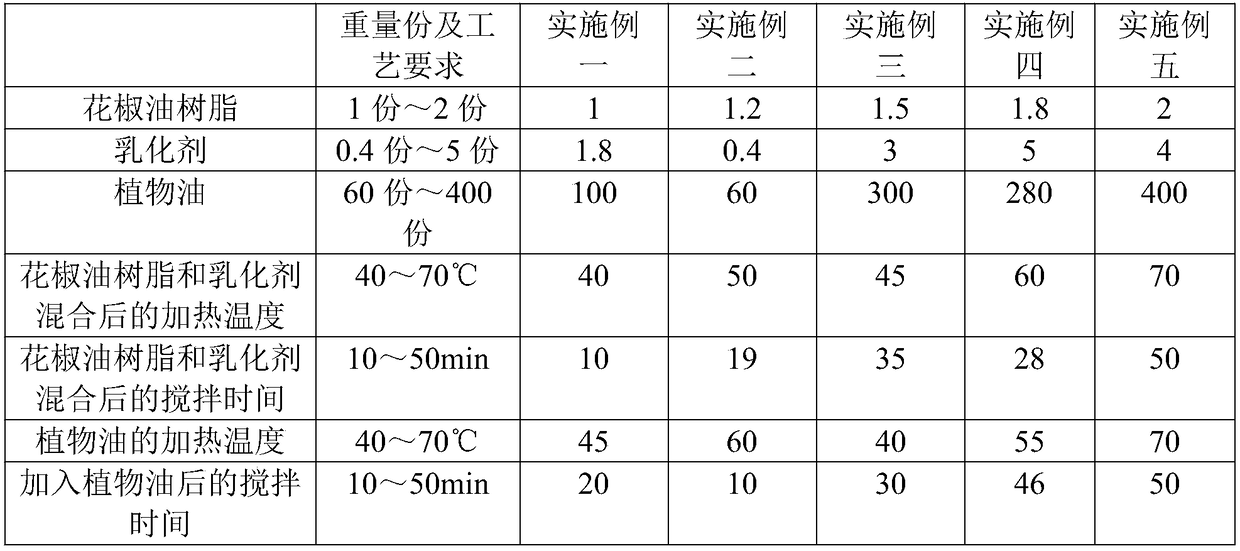

[0036] Embodiment 1: get the Zanthoxylum bungeanum that 20kg Hancheng Dahongpao supercritically has extracted, mix bell pepper powder 0.5kg and 10% glucose water 1.5kg, and the proportion of Titian spice is: cumin 0.29kg, Amomum 0.11kg , 70g of lemongrass, 60g of star anise powder, 0.29kg of water and mix well. Heat the grade 4 rapeseed oil to medium 140°C, pour in and mix the Sichuan pepper skin mixture, keep stirring and fry at 120°C for 30 minutes, then add Titian spice and stir-fry at 120°C for a frying time of 20min, then cooled, pressed and filtered through a 600-mesh filter screen to obtain sesame oil and fried pepper skin.

[0037] Preparation of mixed pepper oil: take Hancheng Dahongpao pepper pure supercritical pepper oleoresin 1.3kg, mix with 2kg caprylic glyceride, heat to 60°C, keep stirring for 20min, add 96.7kg, 60°C first-class rapeseed oil and stir Mix for 20min. Among them, the numbness of the prepared pepper oil is equivalent to 1 / 3 of the pure Hancheng Da...

Embodiment 2

[0039] Embodiment 2: get the Zanthoxylum bungeanum skin that the supercritical extraction of 5kg Sichuan Jinyangqing Zanthoxylum bungeanum and 15kg Gansu Fujiao is mixed, stir in the glucose water 2kg of bell pepper powder 0.8kg and 8% (W / W), the spice proportioning It is: 0.35kg of cumin, 0.2kg of Amomum, 70g of lemongrass, 80g of star anise powder, 0.25kg of water and mix well. Heat the first-grade rapeseed oil to medium 130°C, pour in the mixed pepper skin mixture, keep stirring and fry at 105°C for 40 minutes, then add Titian spice and stir-fry at 110°C for a frying time of 25min, then cooled, pressed and filtered through a 600-mesh strainer to obtain the sauteed sesame oil and fried Chinese pepper skin.

[0040] Preparation of mixed pepper oil: take Sichuan Jinyang pepper pure supercritical pepper oleoresin 0.35kg and Gansu Fujiao pure critical pepper oleoresin 0.65kg, mix with 2.37kg caprylic acid glyceride, heat to 60 ℃, keep stirring for 30min, add 96.63 kg, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com