Active unwinding device for double-blocking-edge bobbin of bobbin winder

A winding machine and bobbin technology, applied in transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of yarn breakage, hairiness increase, wear and other problems, and achieve simple structure and not easy to break Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

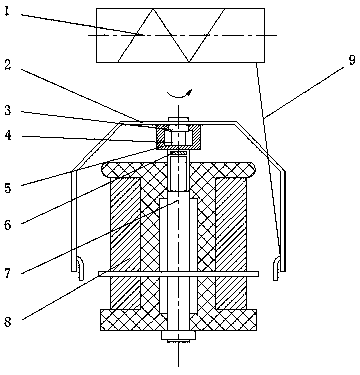

[0013] like figure 1 As shown, an active unwinding device for a bobbin with double ribs of a winding machine, including a yarn guide hook 2, a small shaft 3, a bearing 4, a bearing seat 5 and a pin 6, and the yarn guide hook 2 is installed On the upper end of the double-ribbed bobbin 8, a bobbin shaft 7 is provided inside the double-ribbed bobbin 8, which is transitionally matched with it, and the double-ribbed bobbin 8 is provided with a bearing seat 5 under the yarn guide hook , the bearing housing 5 is provided with a bearing 4, the yarn guide hook 2 is fixed with a small shaft 3 through a top wire, the small shaft 3 is in interference fit with the inner ring of the bearing 4, and the outer ring of the bearing 4 and the bearing housing 5 pass through Fitting constitutes the thread guide hook assembly, the bearing housing 5 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com