Industrial waste heat recovery system and peak-load-regulating heat supply coupling technology

A technology of recycling system and industrial waste heat, applied in the field of industrial waste heat recovery, can solve the problems of energy waste, high cost of clean energy, consumption of electric energy and water resources, etc., to achieve expansion of heating area, good waste heat utilization effect, absorption and release speed quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

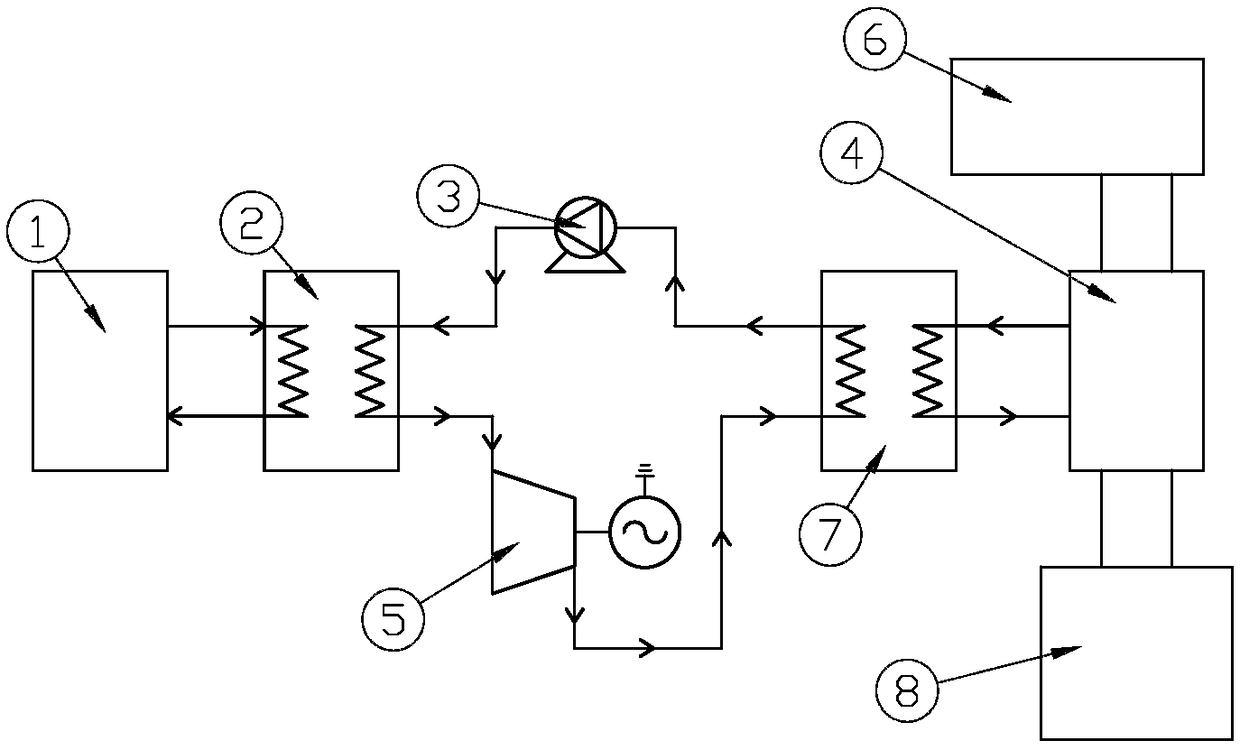

[0010] A coupling technology of industrial waste heat recovery system and peak shaving heat supply, industrial waste heat 1, evaporator 2, working medium pump 3, absorption heat pump 4, working medium generator 5, heat user 6, condenser 7, peak shaving heat source 8 The industrial waste heat 1 transports the industrial waste heat to the evaporator 2, heats the CO2 working medium, and the CO2 working medium is transported to the working medium generator 5, and the CO2 after work is gaseous, still has a certain temperature, and is transported to the condenser 7, The condenser 7 exchanges heat with the absorption heat pump 4, and serves as the low-temperature heat source of the absorption heat pump, and the high temperature produced by the peak-shaving heat source is used as the driving heat source of the absorption heat pump 4, and the obtained heat source is sent to the heat user 6 for heating, After the heat source is driven to work, it is sent back to the peak heat source to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com