Fault positioning circuit and positioning method for high voltage loop interlocking

A fault location and high-voltage loop technology, which is applied in the direction of measuring electricity, measuring electrical variables, and testing electrical devices in transportation, etc., can solve the problems of energy-consuming troubleshooting, inability to accurately locate fault points, troublesome fault point troubleshooting, etc. Achieve the effect of improving troubleshooting efficiency, narrowing the scope of troubleshooting, and facilitating retrieval and viewing

Inactive Publication Date: 2018-12-28

奇瑞新能源汽车股份有限公司

View PDF10 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, once the loop interlock fault is reported, it is very troublesome to troubleshoot the fault point, because there are so many components, connectors and connecting wires, any point disconnection will report a fault, and it needs to be checked one by one, which is time-consuming and labor-intensive.

Later, a large loop on the car was divided into the main discharge loop, the high-voltage accessory loop, and the fast and slow charging loop to reduce the scope of the loop. This can narrow the scope of investigation, but it still requires energy to troubleshoot the fault point and cannot accurately locate the fault. point

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

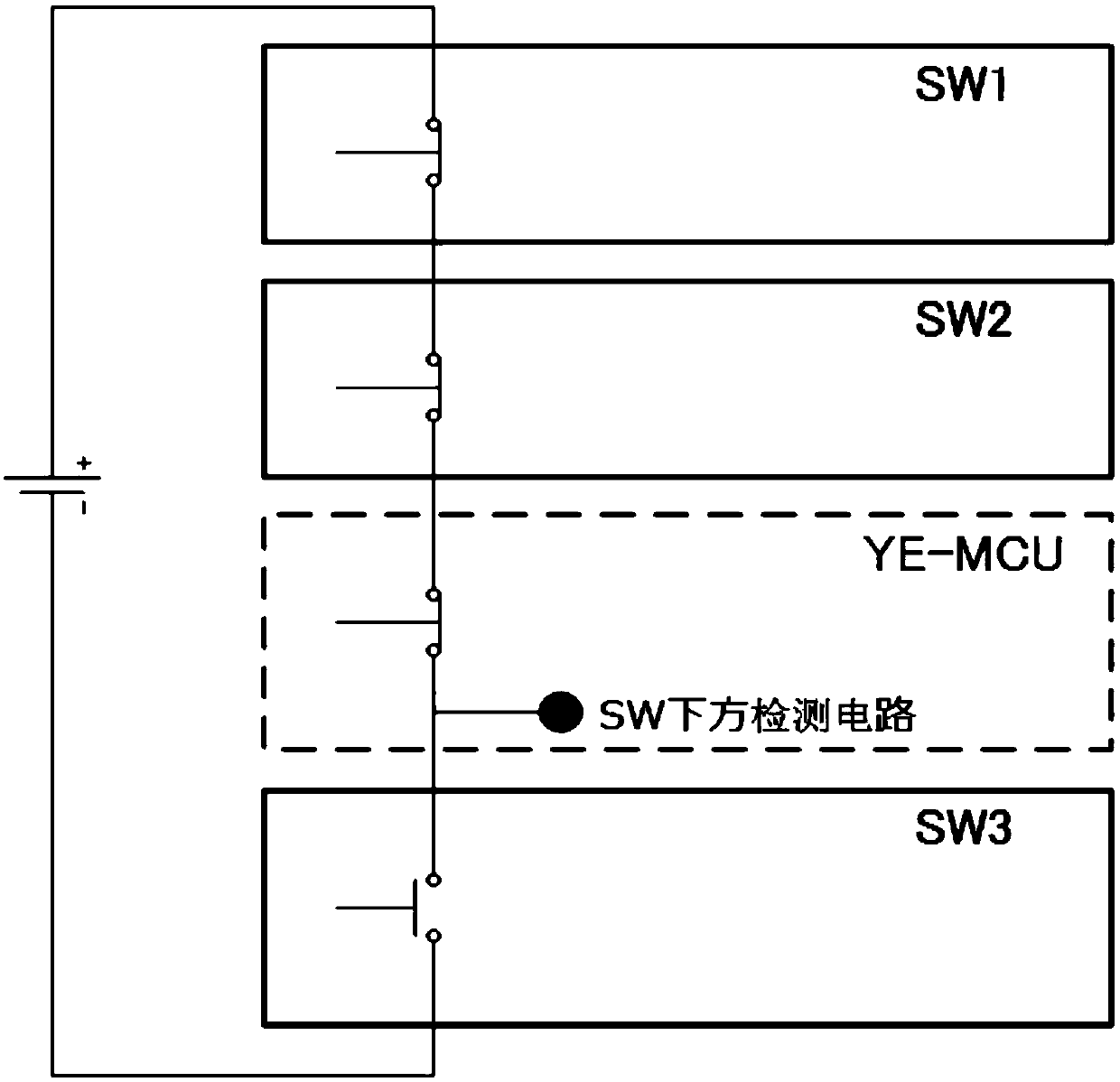

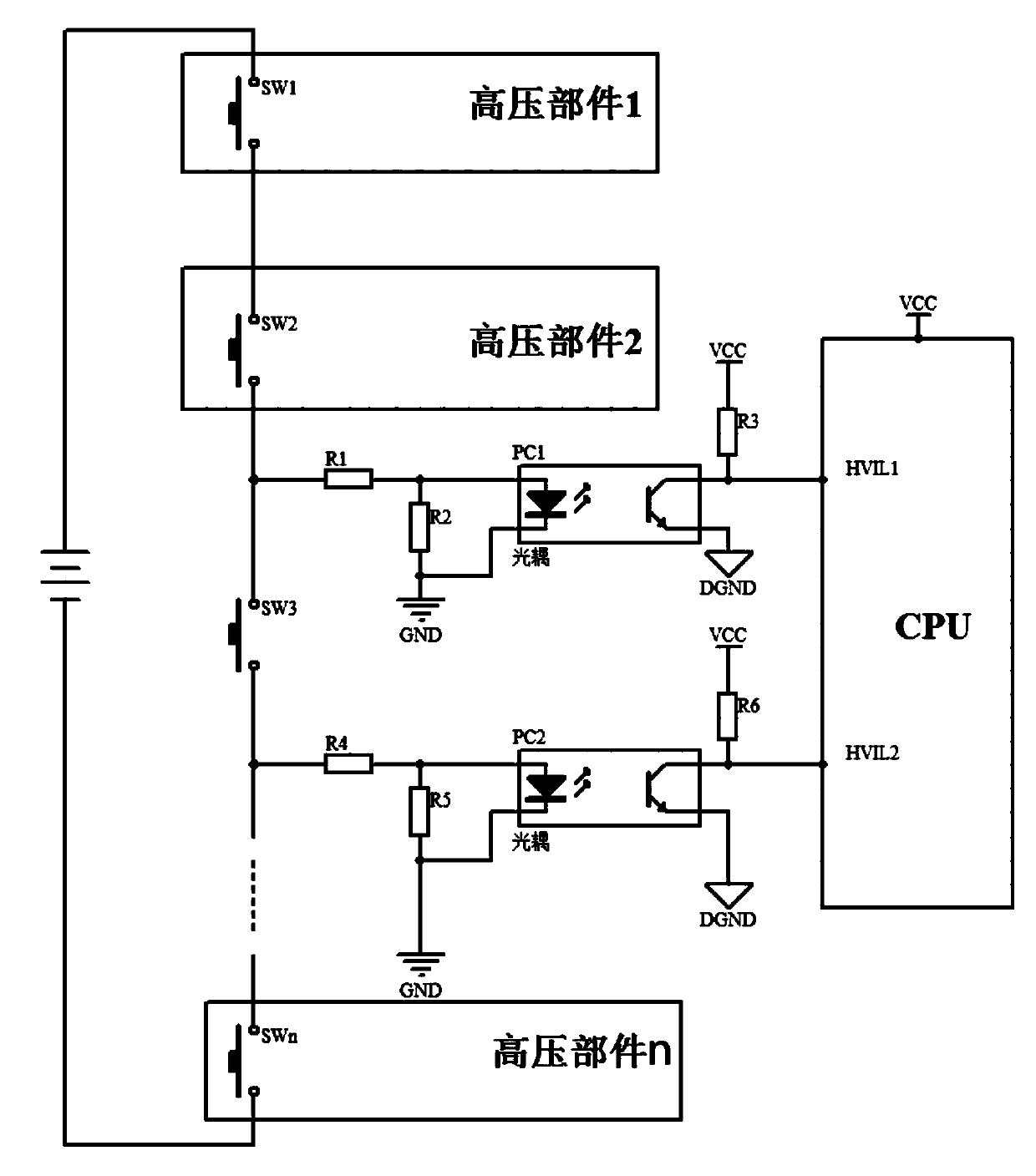

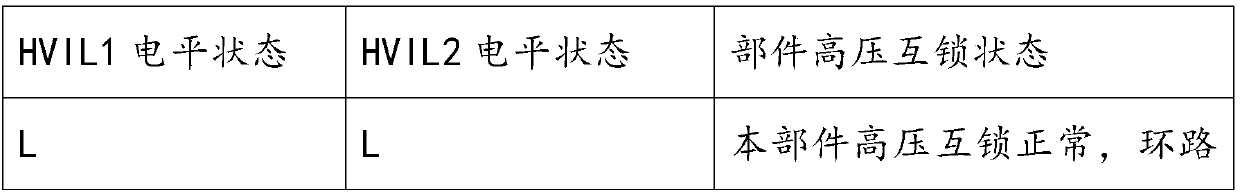

The invention discloses a fault positioning circuit and positioning method for a high voltage loop interlocking. The circuit comprises a potential detecting circuit and a main controller, wherein thepotential detecting circuit sends a potential signal at the front end and the rear end of an interlocking switch of the detected high voltage component to the main controller, and the main controllerdetermines whether the high voltage component corresponding to the interlocking switch interlocks normally and / or an interlocking fault position according to the potential signal at the front end andthe rear end of the interlocking switch. The fault positioning circuit and positioning method for the high voltage loop interlocking has the advantages that the fault position can be quickly positioned after an interlocking fault occurs by determining whether the high voltage component is faulty and the position of the fault relative to the high voltage component according to the potential signalat the front end and the rear end of the interlocking switch of the high voltage component, so that the maintenance can be facilitated, the time and cost of manual troubleshooting are saved, and the troubleshooting efficiency can be greatly improved.

Description

technical field The invention relates to the field of automobile fault detection, in particular to an automobile high-voltage loop interlock fault location circuit and a location method. Background technique With the rapid development of the Xinyuan automobile industry, the voltage level of electric vehicles is also getting higher and higher. At present, the DC bus voltage of mainstream electric vehicles is mostly around 300-400 volts. There are also many high-voltage components on electric vehicles, including charging systems, high-voltage power distribution boxes, energy storage systems (power batteries), electric drive systems, DCDC, air-conditioning compressors, and PTCs. As a result, there are more and more hidden dangers of high-voltage damage, and high-voltage loop interlocking is one of the important measures for electric vehicle high-voltage safety. The high-voltage interlock circuit is to check the electrical integrity (continuity) of the high-voltage components,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01R31/00

CPCG01R31/006

Inventor 姚峰杭孟荀王瑛王晓辉刘新超

Owner 奇瑞新能源汽车股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com