Production system and production control method

A production system and production line technology, applied in the field of production and manufacturing, can solve the problems of high input cost, long production line, poor versatility, etc., and achieve the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

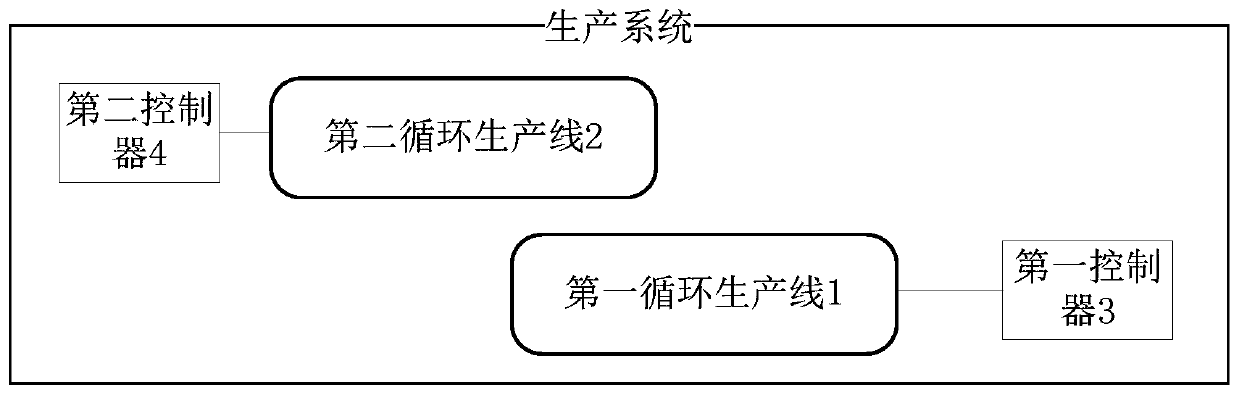

[0037] This embodiment provides a production system, such as figure 1 As shown, the production system includes at least a first circulation production line 1 and a second circulation production line 2, and a first controller 3 for controlling the production tempo of the first circulation production line and a second controller 3 for controlling the production tempo of the second circulation production line. controller 4;

[0038] The first circulation production line 1 and the second circulation production line 2 cooperate with each other for production;

[0039] When the first circulation production line 1 and the second circulation production line 2 are producing at the same time, the total duration of the required production cycle is equal.

[0040] Wherein, according to the system according to claim 1, it is characterized in that, when the first circulation production line and the second circulation production line are producing at the same time, when one of the circulati...

Embodiment 2

[0051] This embodiment provides a production control method, such as Figure 5 As shown, the method includes:

[0052] Step S501, obtaining the model of the product to be processed;

[0053] Step S502, controlling the production tempo of the first type of processing of the first cycle production line according to the model of the product to be processed;

[0054] Step S503, controlling the production tempo of the second type of processing in the first cycle production line according to the model of the product to be processed.

[0055] The control method provided in this embodiment, by controlling the production tempo of the first cycle production line according to the model of the product, saves the investment in production equipment, improves the production efficiency of the product, and makes the whole production line truly realize the intelligence of multiple models and multiple processes. Mixed line production.

Embodiment 3

[0057] This embodiment provides a production control method, such as Image 6 As shown, the method includes:

[0058] Step S601, obtaining the model of the product to be processed;

[0059] Step S602, controlling the production tempo of the second cycle production line according to the model of the product to be processed.

[0060] The control method provided in this embodiment, by controlling the production tempo of the second cycle production line according to the model of the product, saves the investment in production equipment, improves the production efficiency of the product, and makes the whole production line truly realize the intelligence of multi-model and multi-process car body Mixed line production.

[0061] The production system and the production control method provided by the embodiments of the present invention have the same technical features, so they can also solve the same technical problems and achieve the same technical effects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com