Assembly flexible production system and method

A flexible general assembly and production system technology, applied in the field of automobile manufacturing, can solve the problems of waste of resources in the production line, poor adaptability of new products, length of the production line, etc., achieve the effects of saving investment, realizing intelligent mixed-line production, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

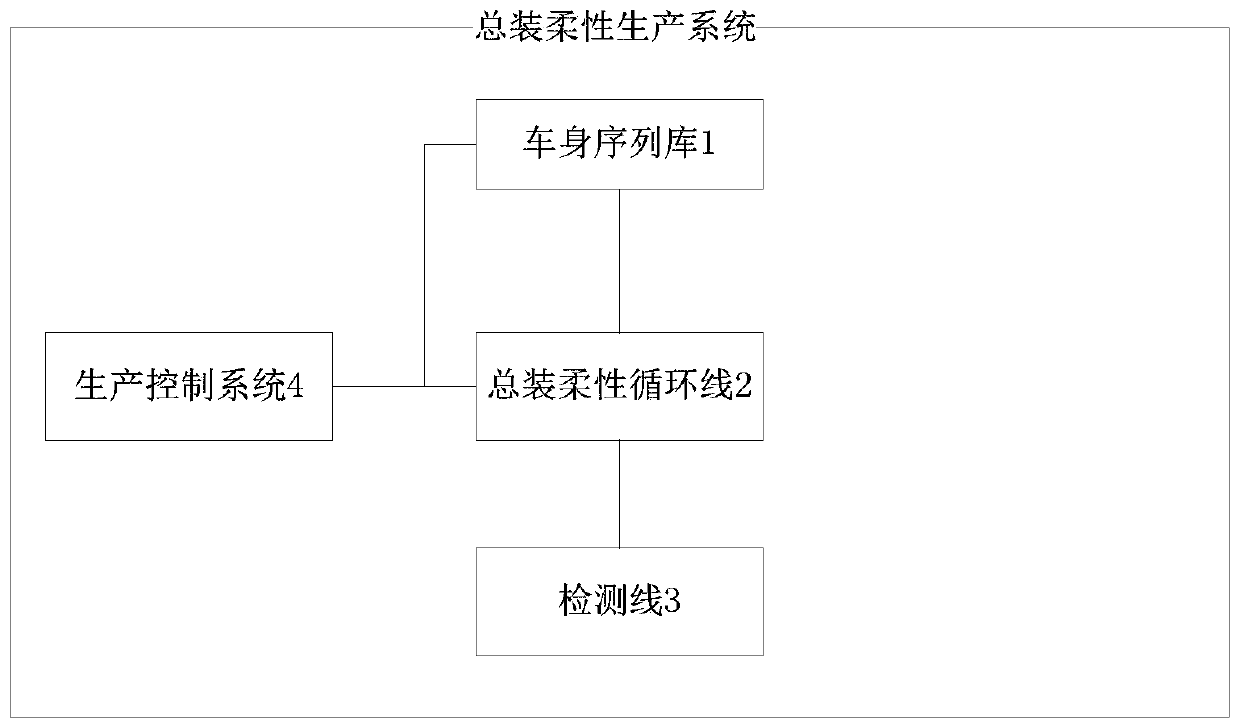

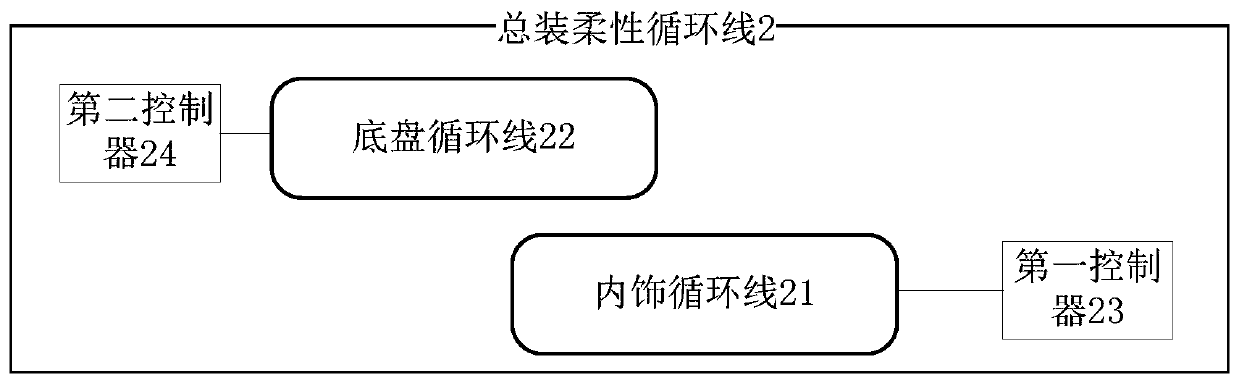

[0050]This embodiment provides a flexible production system for assembly, such as figure 1 As shown, the system includes a body sequence library 1, an assembly flexible circulation line 2, a testing line 3 and a production control system 4;

[0051] The body sequence warehouse 1 is used to receive and execute the first instruction sent by the production control system 4, and complete the warehouse-in operation and warehouse-out operation of different types of bodies;

[0052] The final assembly flexible circulation line 2 is used to receive and execute the second instruction sent by the production control system 4, and adopt the circulation production mode to perform final assembly production on the car bodies released from the car body sequence warehouse 1;

[0053] The inspection line 3 is used for inspecting the body after the assembly and production of the assembly flexible circulation line 2 .

[0054] Among them, the production control system 4 is a highly integrated co...

Embodiment 2

[0062] This embodiment provides a flexible production method for assembly, such as Figure 8 As shown, the method includes the following steps:

[0063] Step S801, sending different types of car bodies to the final assembly flexible circulation line.

[0064] Specifically, the vehicle body is placed on the flexible slide plate transplanting support;

[0065] The body is sent to the final assembly flexible circulation line through the flexible slide plate transplanting bracket.

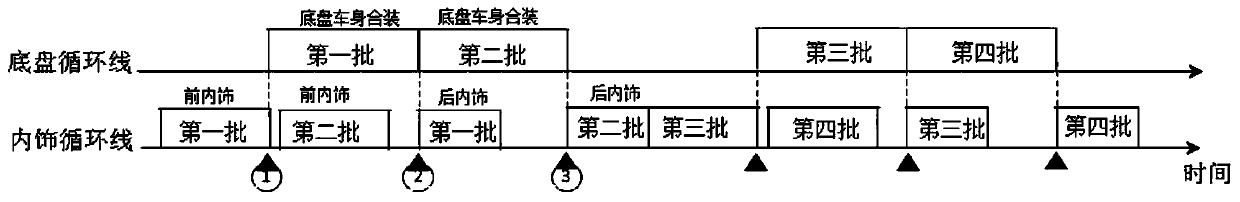

[0066] In step S802, the vehicle body is processed in the assembly flexible circulation line, and the chassis and body are assembled together and glue is dispensed.

[0067] Specifically, the body is processed for the front interior; the body with the front interior processed is assembled with the chassis and the body and glued; the body with the chassis and the body assembled and glued is processed for the rear interior.

[0068] In step S803, the vehicle body processed on the assembly flexible cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com