High-resolution light guide plate image defect detection method

A high-resolution, defect detection technology, applied in the direction of image enhancement, image analysis, image data processing, etc., can solve the problems of detection accuracy and detection time length gap, and achieve the effect of stable algorithm, improved accuracy and simple detection algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

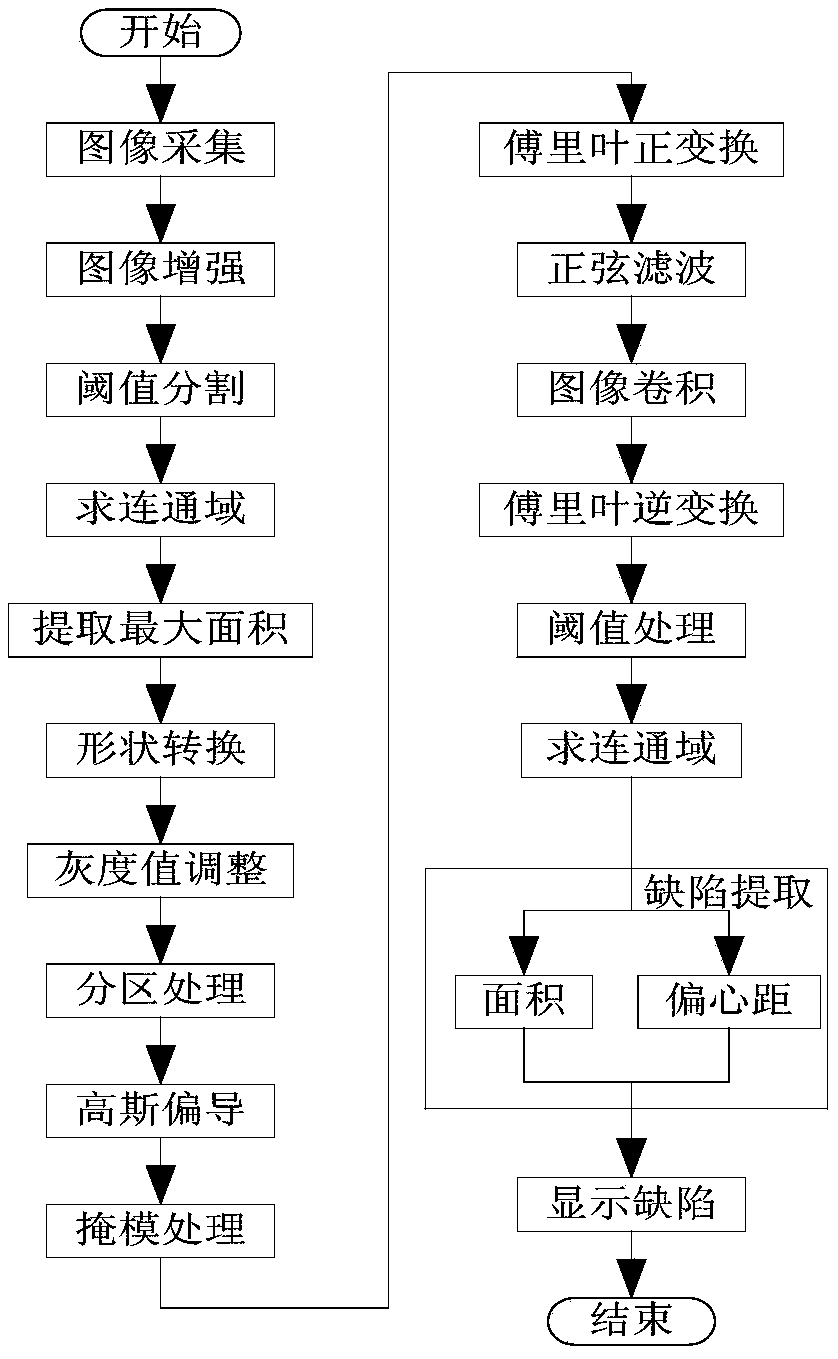

[0089] Embodiment 1, high-resolution light guide plate image defect detection method, such as Figure 1-19 shown, including the following steps:

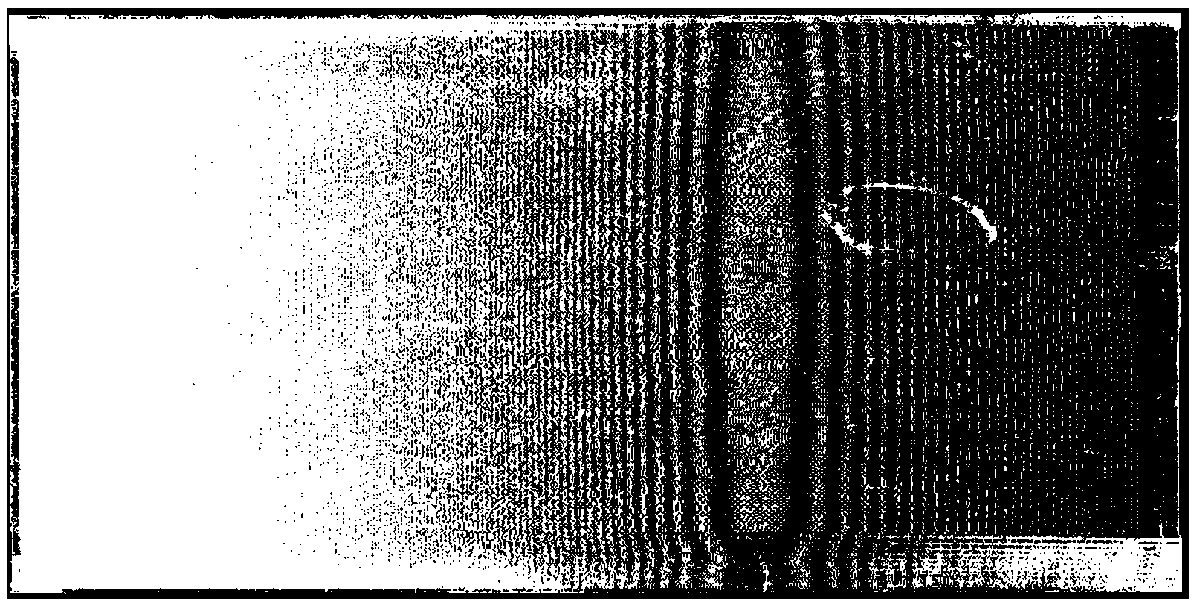

[0090] 1) The defect of the light guide plate is small and difficult to find. In order to detect the defect as much as possible, it is necessary to use a line array camera to collect the original image of the light guide plate; perform step 2;

[0091] After observation, it is found that the image of the light guide plate collected by the line scan camera meets the requirements in terms of texture clarity and light uniformity, which is very beneficial for the processing of follow-up work.

[0092] 2) Perform image enhancement on the original image of the light guide plate to obtain an enhanced image of the light guide plate; perform step 3;

[0093] The original image of the light guide plate collected by the line array camera has textures that are not clear enough in some areas and the details are slightly blurred. Perform detail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com