A Low-Voltage Differential Signal Driver with Common-Mode Feedback

A low-voltage differential signal and signal driver technology, which is applied in the fields of logic circuit coupling/interface using field effect transistors, baseband system components, logic circuit connection/interface layout, etc. The problem of large die point resistance and large area occupied, to achieve the effect of simple bias circuit, less components, and avoiding area consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

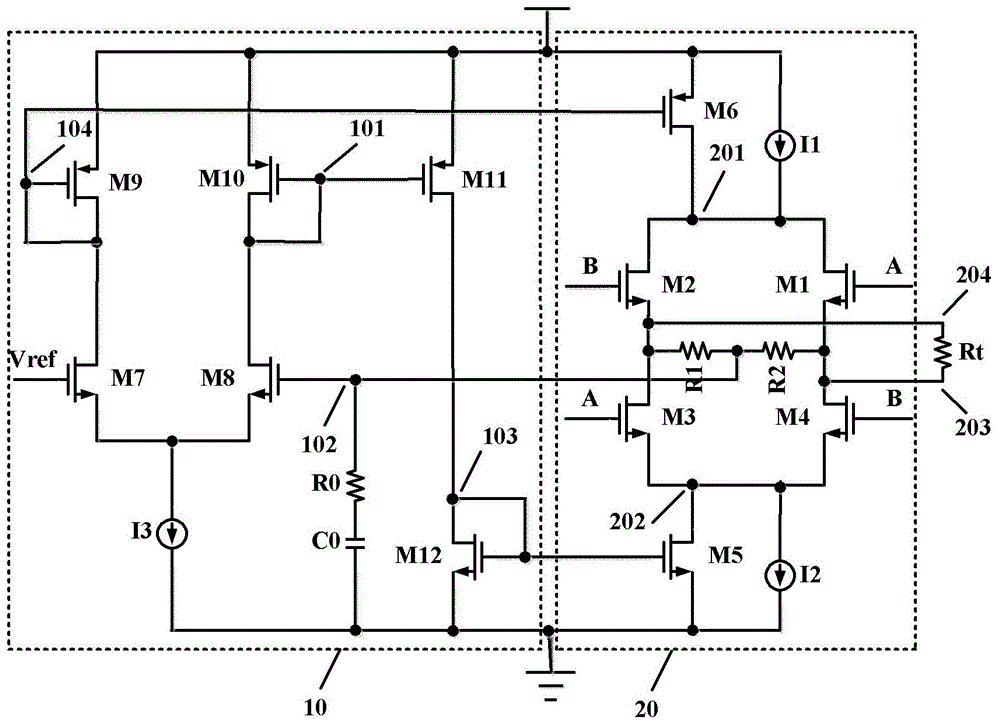

[0028] figure 1 It is a circuit schematic diagram of an LVDS driver with common-mode feedback in the prior art. The LVDS driver includes an amplifier, a negative feedback loop, a current bias and a driving circuit; wherein the single-stage circuit composed of M7-M10 and a current source I3 The differential amplifier is used to amplify the difference between the voltage at node 102 and the reference voltage Vref; the negative feedback loop composed of M5, M6, M11, M12, R1, and R2 is combined with the amplifier to stabilize the common mode of the output LVDS signal Voltage; current bias I1 and I2 provide a suitable bias current for the drive circuit; the drive circuit is used to generate LVDS signals.

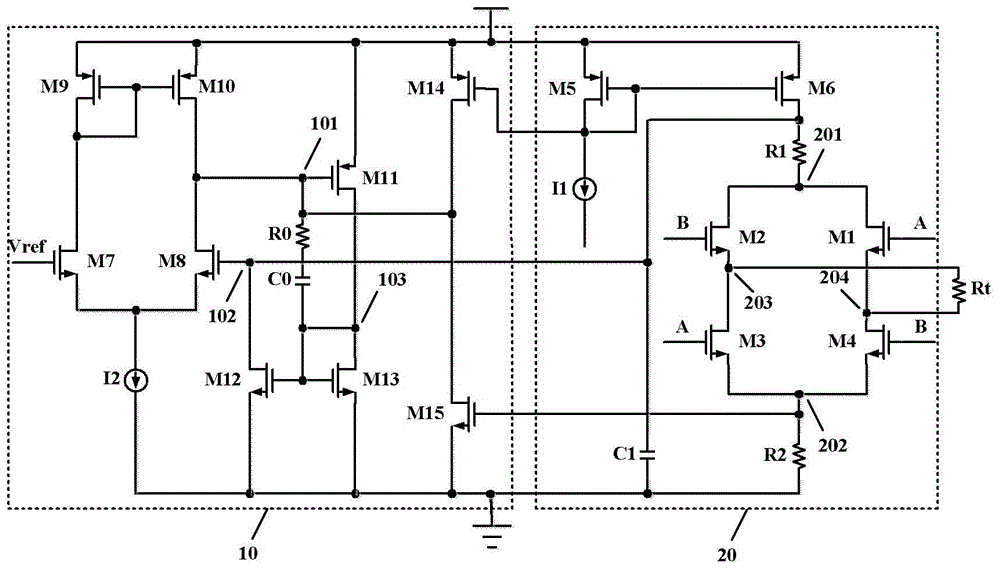

[0029] figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com