Hydrogen-incoming integrated disproportionate block and fuel cell with the same

A technology of hydrogen intake and manifold, applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of large volume and cavity, poor integrity and reliability, and difficult quality control, and achieve simple installation and manufacturing, and integrity Strong, easy quality control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

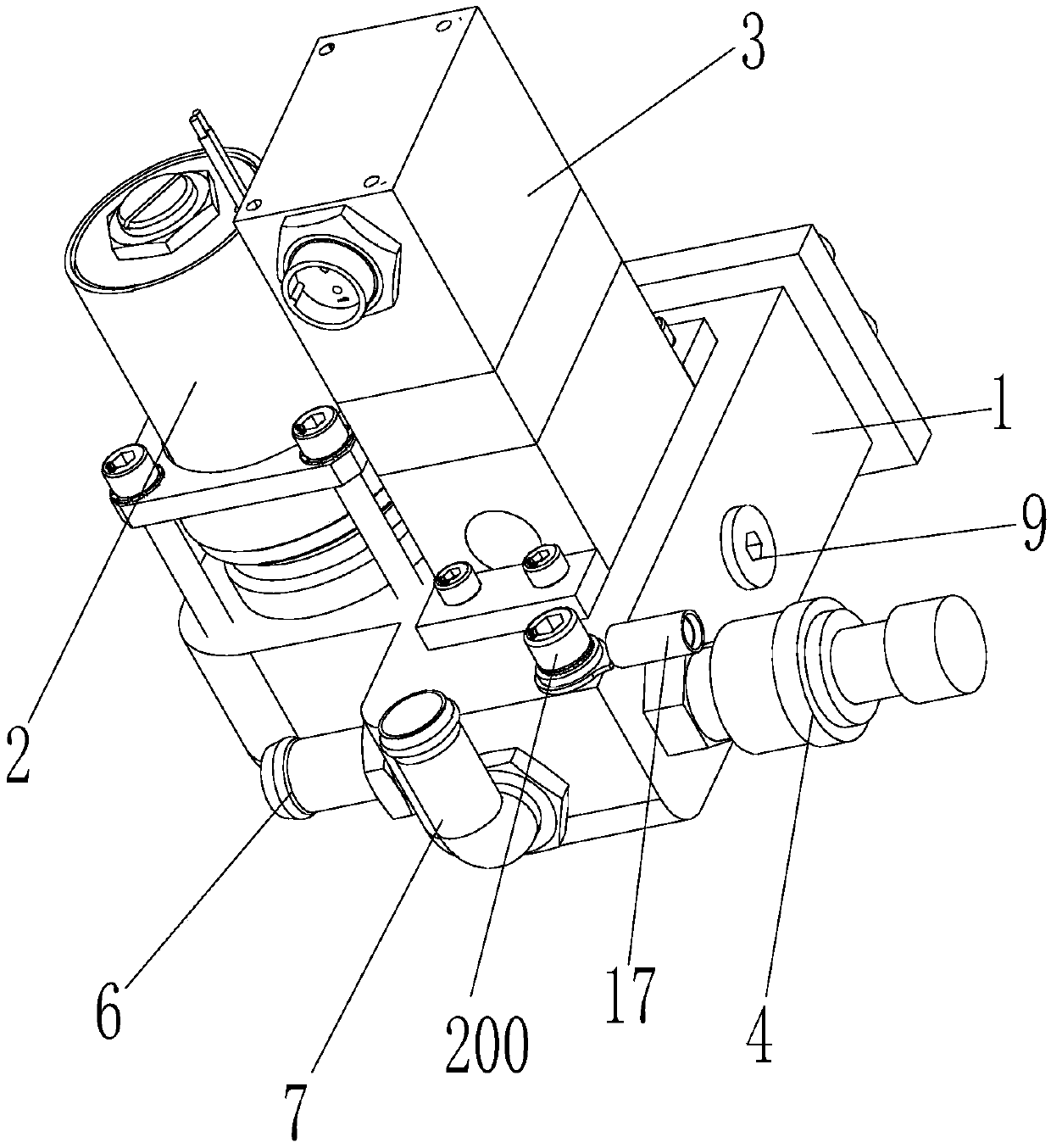

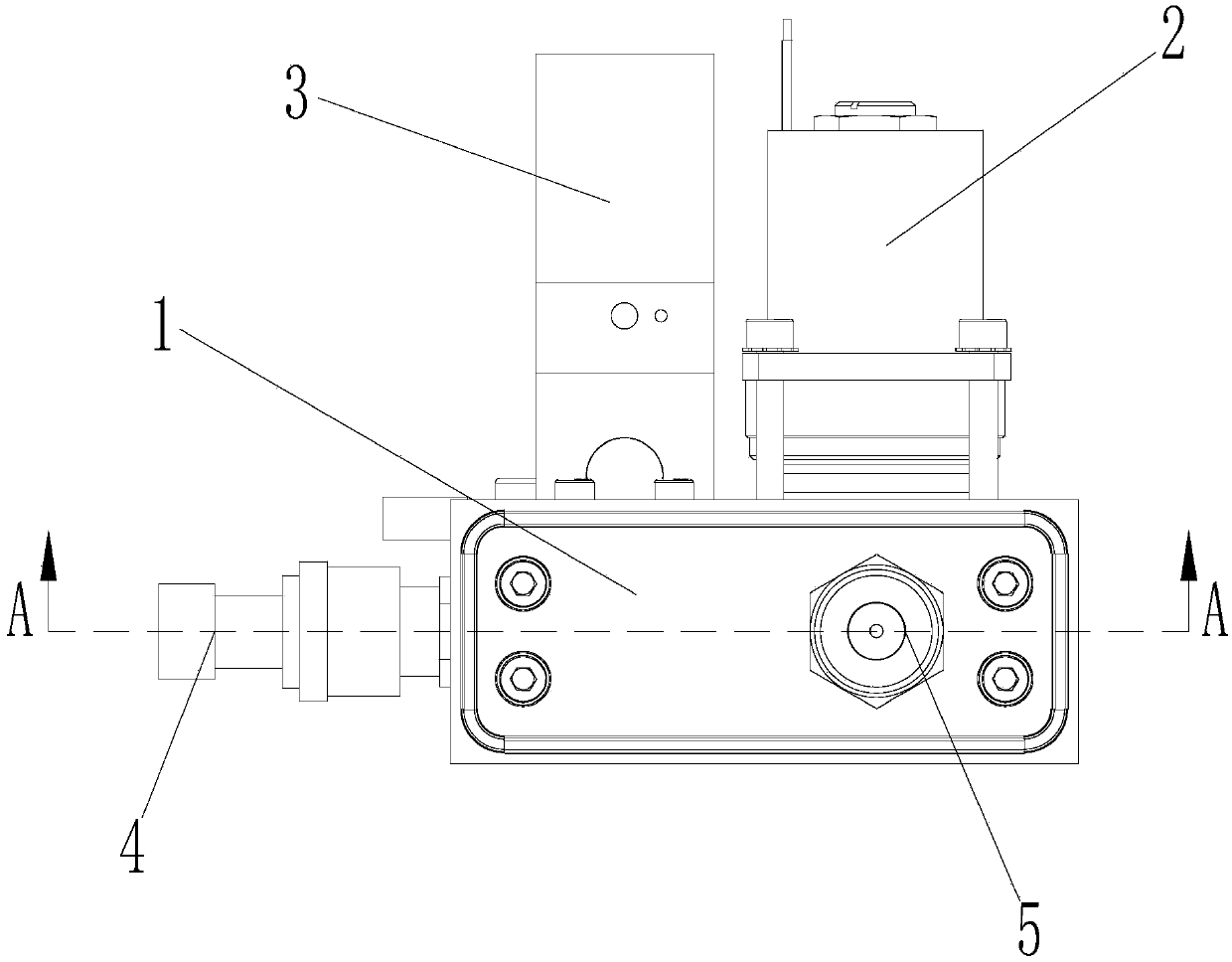

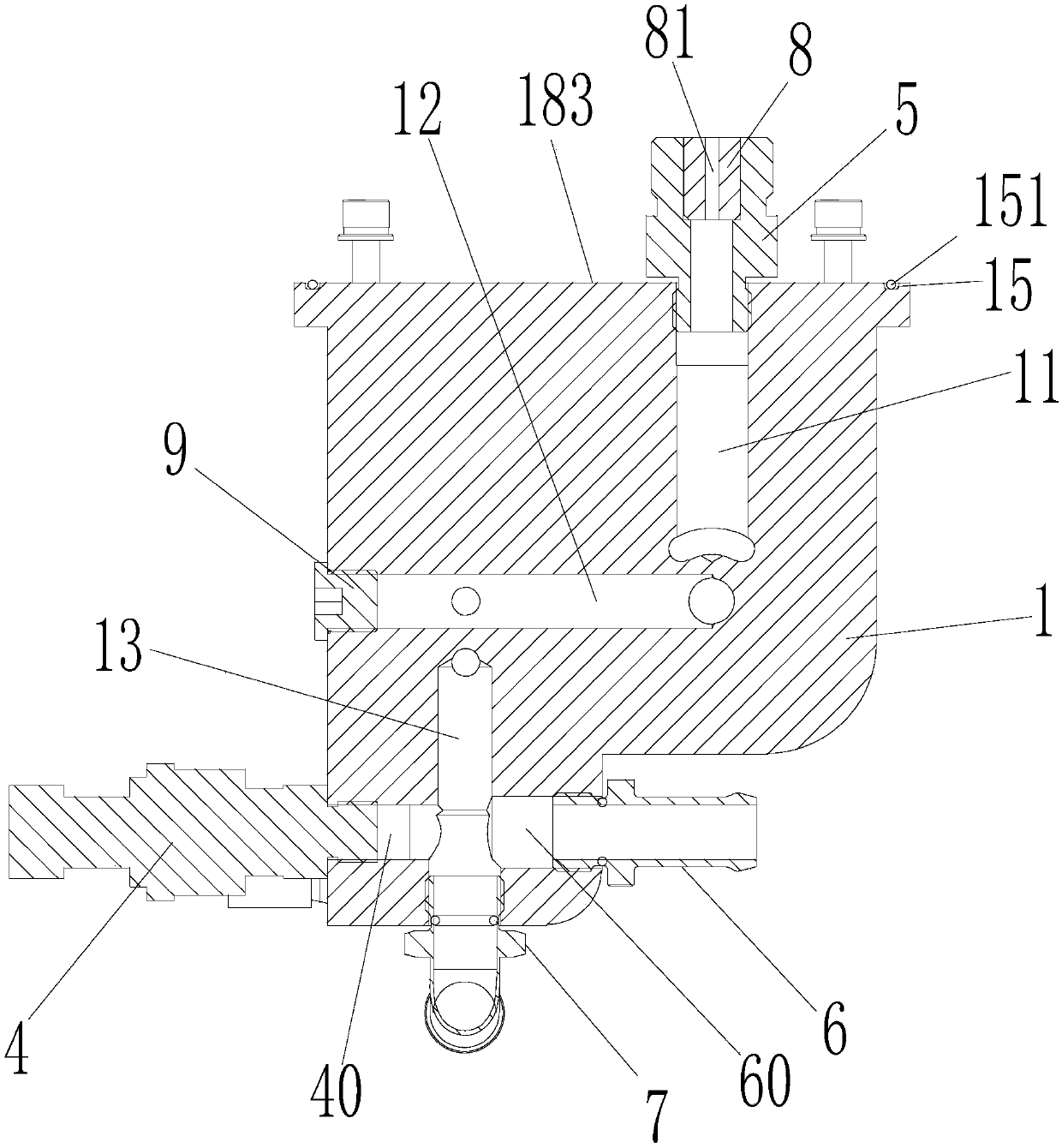

[0035] like Figure 1 to Figure 6 As shown, this embodiment provides a hydrogen inlet integrated manifold, including a manifold 1, a shut-off valve 2, a proportional regulating valve 3, a pressure sensor 4, a hydrogen inlet connector 5, a hydrogen circulation pump connector 6 and a hydrogen outlet connector 7 , the inside of the manifold block 1 is provided with a first flow channel 11, a second flow channel 12 and a third flow channel 13 for the flow of hydrogen, the first inlet 111 of the first flow channel 11 is installed into the hydrogen joint 5, and the first flow channel 11 of the first flow channel 11 The outlet 112 is connected with the second inlet 121 of the second flow channel 12 through the stop valve 2, and the second outlet 122 of the second flow channel 12 is connected with the third inlet 131 of the third flow channel 13 through the proportional regulating valve 3, and the third flow The third outlet 132 of the channel 13 is equipped with a hydrogen outlet con...

Embodiment 2

[0042] like Figure 9 and Figure 10 As shown, a fuel cell includes a box body 101, a box cover 102, a stack module 103, a hydrogen inlet manifold block 10, a stack gas outlet valve group 104, a hydrogen circulation pump 105, an air circuit system 106, and a cooling system 107 and a low-voltage control system 108, wherein the stack module 103, the low-voltage control system 108, the hydrogen inlet manifold block 10, and the stack gas outlet valve group 104 are all installed in the box body 101, and the hydrogen inlet manifold block 10 is For any one of the hydrogen inlet manifold 10 described in the first embodiment above, the pressure signal detected by the pressure sensor is sent to the low-pressure control system, and the low-pressure control system 108 controls the opening or closing of the cut-off valve 2 and the proportional regulating valve 3, and the externally provided Hydrogen is sent to the stack module 103 through the hydrogen inlet manifold 10, and the residual h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com