a high voltage connector

A technology of high-voltage connectors and sockets, which is applied in the direction of connection, two-part connection device, and parts of the connection device. It can solve problems such as easy contact failure, poor contact, carbonization of male terminals or female terminals, and achieve the goal of eliminating misuse. Possibility, reduction of stretch unevenness, effect of ensuring good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

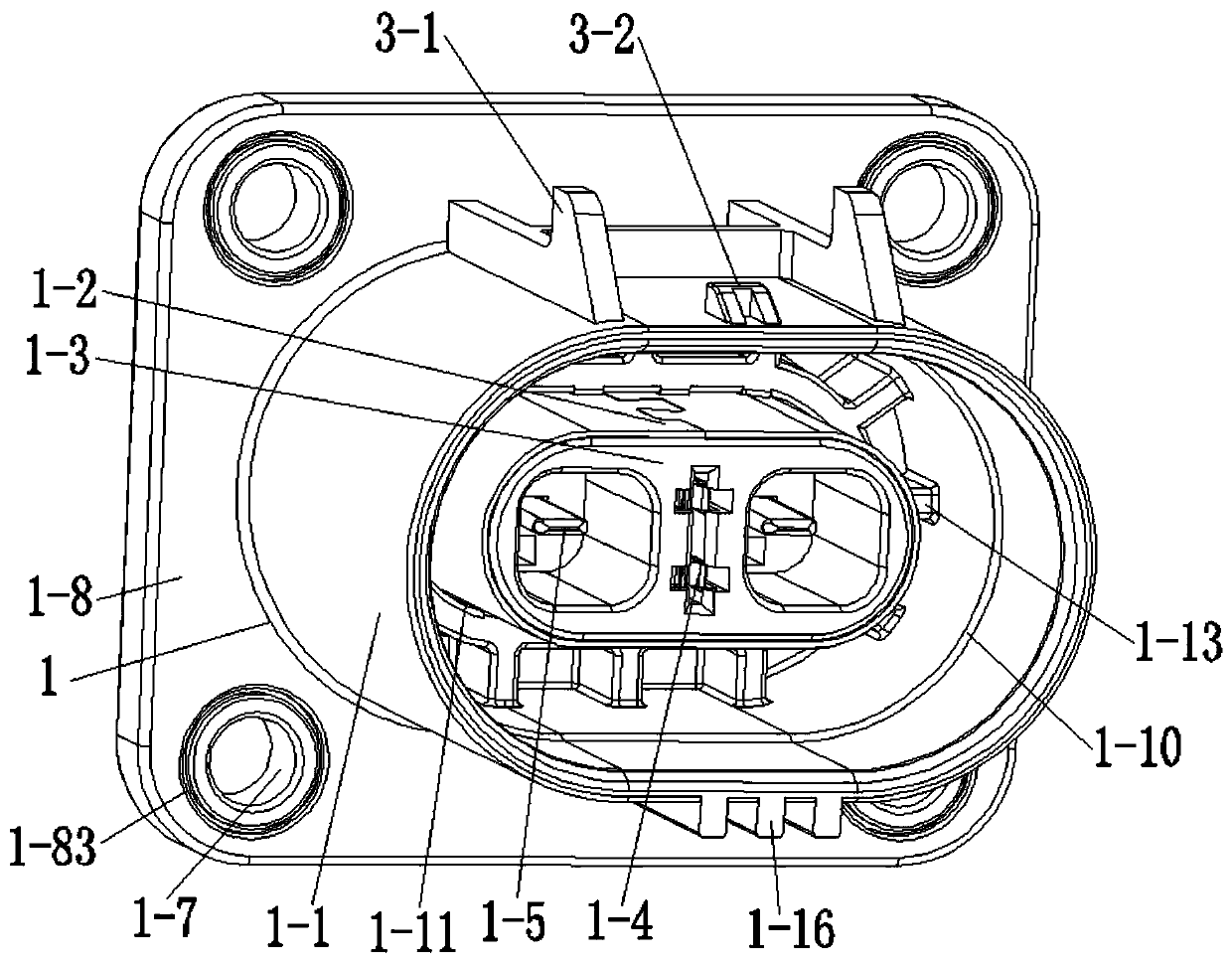

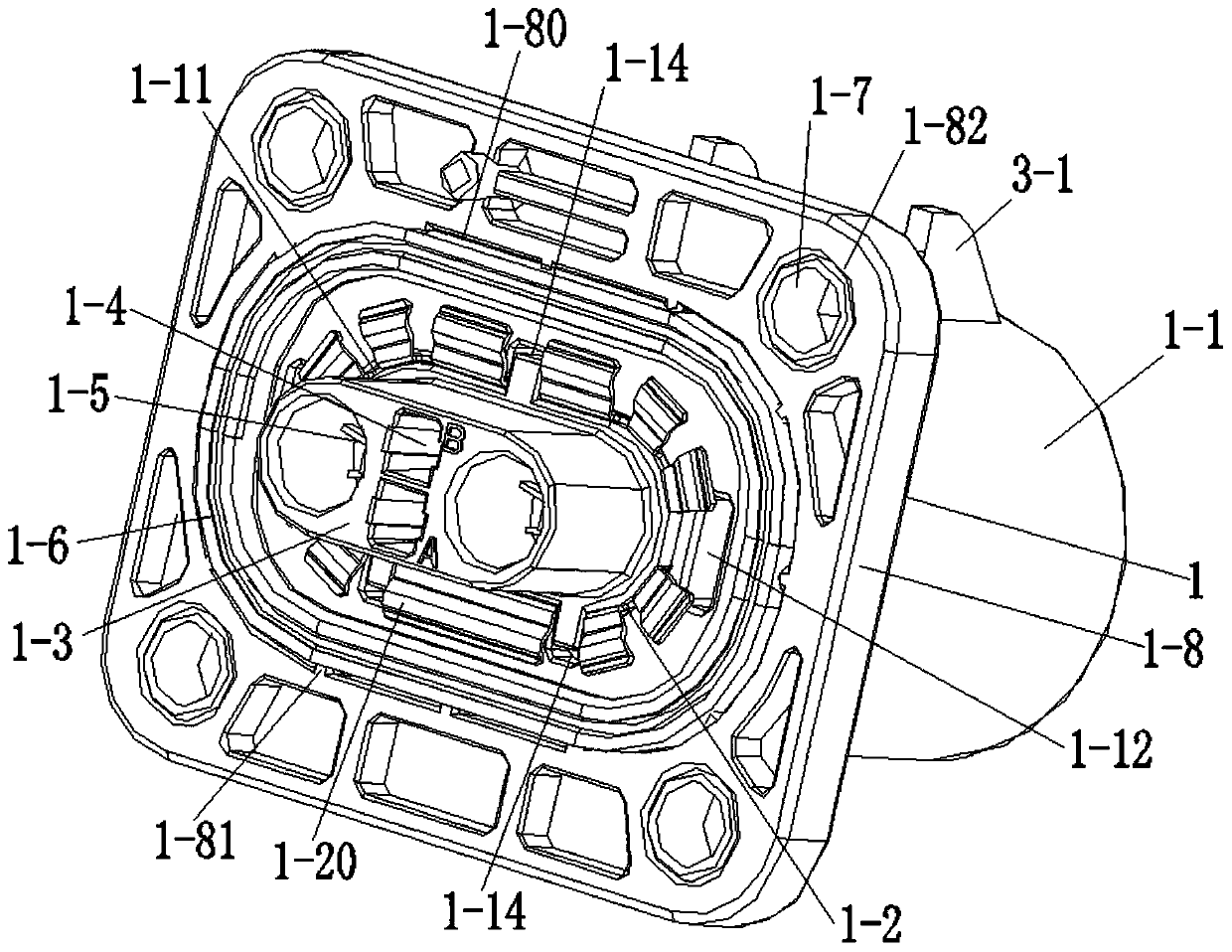

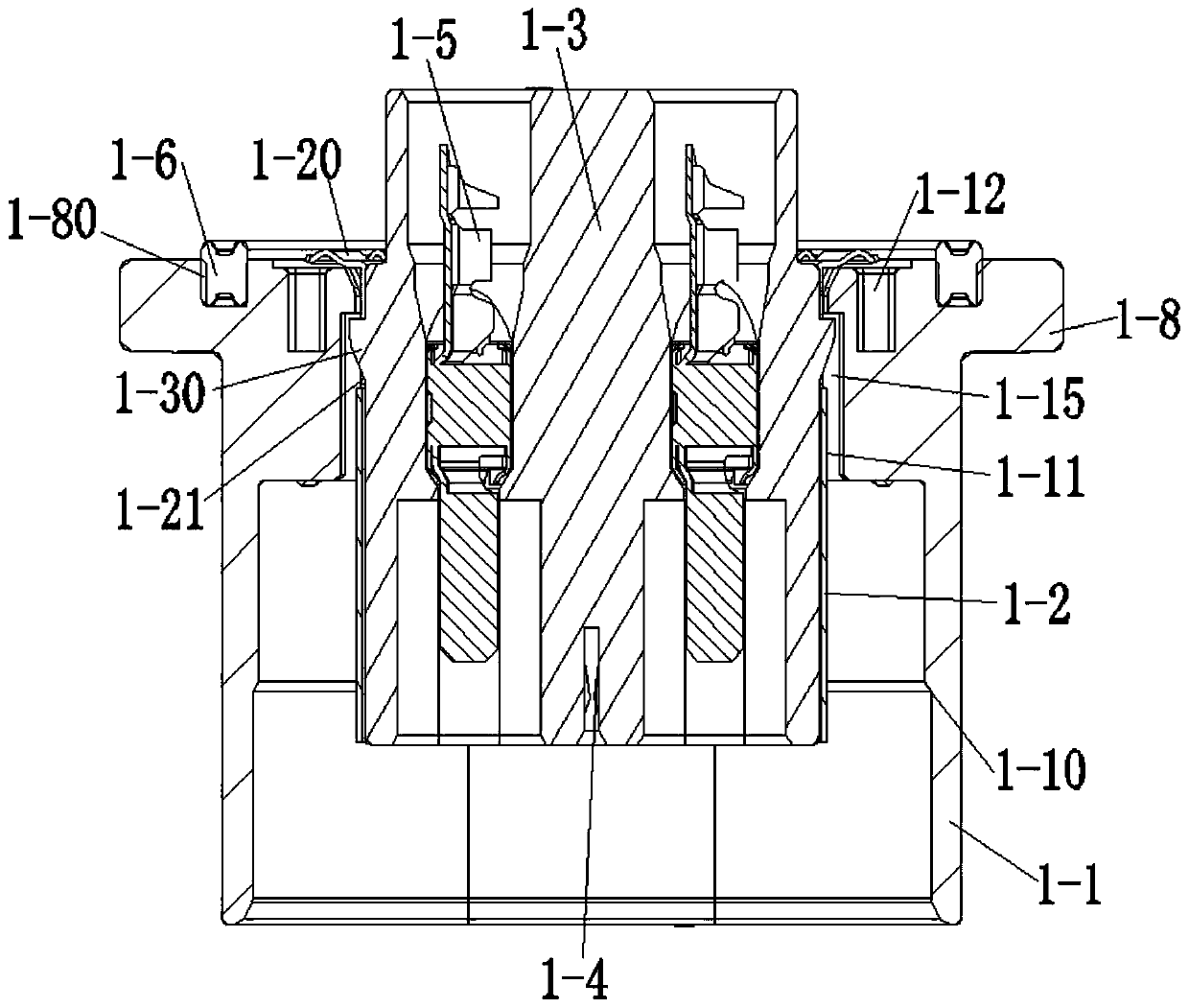

[0036] Figure 1-19 The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings: a high-voltage connector includes a plug assembly 1, a socket assembly 2 and a socket lock 3, the plug assembly 1 includes a plug housing 1-1, a plug shielding shell 1 -2 and the plug inner core 1-3, the bottom of the plug housing 1-1 is provided with a mounting seat 1-8, and the upper end surface of the plug housing 1-1 is provided with two primary locks 3-1 and a secondary lock 3-2, the lower end surface of the plug housing 1-1 is provided with a number of error-proof keys 1-16, the socket assembly 2 is composed of the socket housing 2-1, the socket shielding shell 2- 2. Socket inner core 2-3, female terminal 2-4, interlocking male terminal 2-5, socket cover 2-6, threading cover 2-7, inner shielding ring 2-8, outer shielding ring 2-9, seal The wire body 2-101 is composed of a sealing ring 2-11, two male terminals 1-5 and an in...

Embodiment 1

[0041] The installation method of the whole device, the first step is to install the plug inner core 1-3 into the plug shielding shell 1-2, and place the triangular blocks 1-30 on both sides of the plug inner core 1-3 in the plug shielding shell 1-2 In the avoidance grooves 1-21 on both sides, place an error-proofing bump 1-31 on the upper end face of the plug inner core 1-3 in a position avoidance groove 1-21 on the upper end face of the plug shield shell 1-2, and at the same time the plug The two error-proofing bumps 1-31 on the lower end surface of the inner core 1-3 are located in the two avoidance grooves 1-21 on the lower end surface of the plug shielding shell 1-2 to realize the plug shielding shell 1-2 and the plug inner core 1-2. 3 precision fit; the second step, insert the plug shielding shell 1-2 obtained in the first step and the plug inner core 1-3 together from the inner core jack 1-11 into the plug housing 1-1, wherein , the triangular blocks 1-30 on both sides ...

Embodiment 2

[0043] For the secondary arc-proof lock of the high-voltage connector, when the plug assembly 1 and the socket assembly 2 are inserted into each other, first insert the socket lock 3 into the long slot 3-6 on the slot plate 3-5, and insert the socket lock 3 into the long slot 3-6. 3-6 can be slidably connected, and then insert the plug assembly 1 into the socket assembly 2. When the primary latch 3-1 on the plug housing 1-1 passes over the limit hook 3-40 at the lower end of the pressing plate 3-4, At this time, the male terminals 1-4 are inserted into the female terminals 2-4 and are in contact, but they are not energized with each other, and then the plug assembly 1 is further inserted into the inside. When the secondary lock 3-2 moves to the end face of the lock hook 33 When the interlocking male terminal 2-5 is inserted into the interlocking female terminal 1-5, the connection between the interlocking male terminal 2-5 and the interlocking female terminal 1-5 is equivalent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com