Processing method of dehydrated vegetable product

A processing method and technology for dehydrating vegetables, which are applied in the direction of preservation of fruits/vegetables by dehydration, preservation of fruits/vegetables by freezing/refrigeration, and food drying, etc., can solve the problems of loss of nutrients, inability to return to the original state, and poor rehydration of vegetables, etc. To achieve the effect of reducing nutrient loss, improving bonding strength and improving rehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

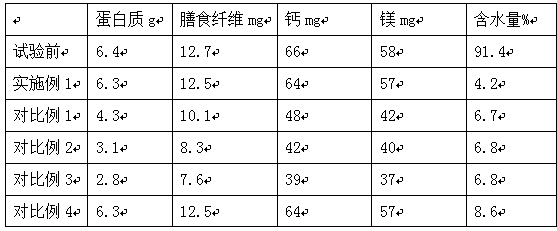

Examples

Embodiment 1

[0024] A processing method of dehydrated vegetable products, the specific steps are as follows:

[0025] 1) Select fresh vegetables, remove pests, rotten and shriveled parts, rinse with clean water and soak in 30% salt solution;

[0026] 2) Take out the soaked vegetables and drain the water, and then cut them into slices, filaments or strips according to the product requirements;

[0027] 3) Move the sliced vegetables into a vacuum container, pressurize to 2MPa, then pass in liquid carbon dioxide whose volume is 1 / 4 of the container, raise the temperature to 50°C, keep it warm for 5 minutes, and then turn on the pressure release switch to release the pressure to Atmospheric pressure, so that all the gas is discharged;

[0028] 4) Turn off the pressure release switch, increase the pressure to 4MPa for the second time, pass in the emulsion with a volume of 1 / 3 of the container, keep the pressure for 6 minutes, then turn on the pressure release switch, release the pressure to ...

Embodiment 2

[0039] A processing method of dehydrated vegetable products, the specific steps are as follows:

[0040] 1) Select fresh vegetables, remove pests, rotten and shriveled parts, rinse with clean water and soak in 32% salt solution;

[0041] 2) Take out the soaked vegetables and drain the water, and then cut them into slices, filaments or strips according to the product requirements;

[0042] 3) Move the sliced vegetables into a vacuum container, pressurize to 2.5MPa, then pass in liquid carbon dioxide whose volume is 1 / 4 of the container, raise the temperature to 55°C, keep warm for 4 minutes, and then turn on the pressure release switch to release the pressure To normal pressure, so that all the gas is discharged;

[0043] 4) Turn off the pressure relief switch, increase the pressure to 4.5MPa for the second time, pass in the emulsion with a volume of 1 / 3 of the container, keep the pressure for 5 minutes, then turn on the pressure relief switch, release the pressure to normal...

Embodiment 3

[0054] A processing method of dehydrated vegetable products, the specific steps are as follows:

[0055] 1) Select fresh vegetables, remove pests, rotten and shriveled parts, rinse with clean water and soak in 35% salt solution;

[0056] 2) Take out the soaked vegetables and drain the water, and then cut them into slices, filaments or strips according to the product requirements;

[0057] 3) Move the sliced vegetables into a vacuum container, pressurize to 3MPa, and then pass in liquid carbon dioxide whose volume is 1 / 3 of the container, raise the temperature to 60°C, keep it warm for 3 minutes, and then turn on the pressure release switch to release the pressure to Atmospheric pressure, so that all the gas is discharged;

[0058] 4) Turn off the pressure release switch, pressurize to 5MPa for the second time, pass in the emulsion with a volume of 1 / 2 of the container, keep the pressure for 4 minutes, then turn on the pressure release switch, release the pressure to normal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com