Auxiliary disassembly tool for fuel tank cap clamp for automobile painting

A technology for disassembling and assembling tools and fuel tank caps is applied in the field of auxiliary disassembling and disassembling tools for fuel tank cap clamps for automobile painting, which can solve the problems of paint sticking to the skin and clothes, consuming a lot of manpower, affecting the production rhythm, etc., so as to improve the work efficiency. Efficiency and output, increase production takt time, reduce workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

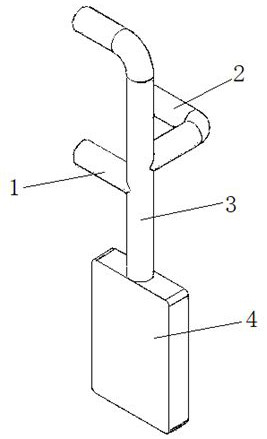

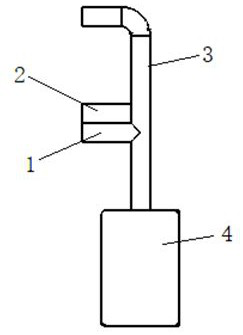

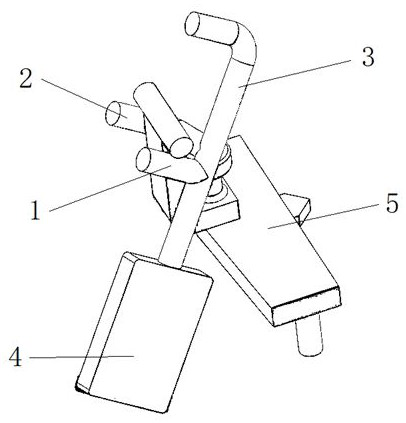

[0022] Please see attached figure 1 and attached figure 2 , a fuel tank cap clamp auxiliary dismounting tool for automobile painting, comprising a first support rod 1, a second support rod 2, a toggle lever 3 and an operating handle 4; one end of the toggle lever 3 is connected to the operating handle 4, and the The other end of the moving rod 3 is bent into an L-shaped toggle head structure; the first support rod 1 is a straight rod structure and is connected to the middle of the toggle rod 3, and the second support rod 2 is an L-shaped curved rod structure and is connected to the toggle The middle part of the rod 3 is located on one side of the first support rod 1; the first support rod 1 is used as a rotating shaft, and the rotating force arm is formed between the second support rod 2, the toggle rod 3 and the operating handle 4, which inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com