A double-wall corrugated pipe tee connector

A technology of double-wall bellows and connectors, which is applied in the direction of pipe/pipe joint/fitting, passing element, sleeve/socket connection, etc., which can solve problems such as inability to guarantee product quality, inability to weld uniformly, and potential safety hazards in welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

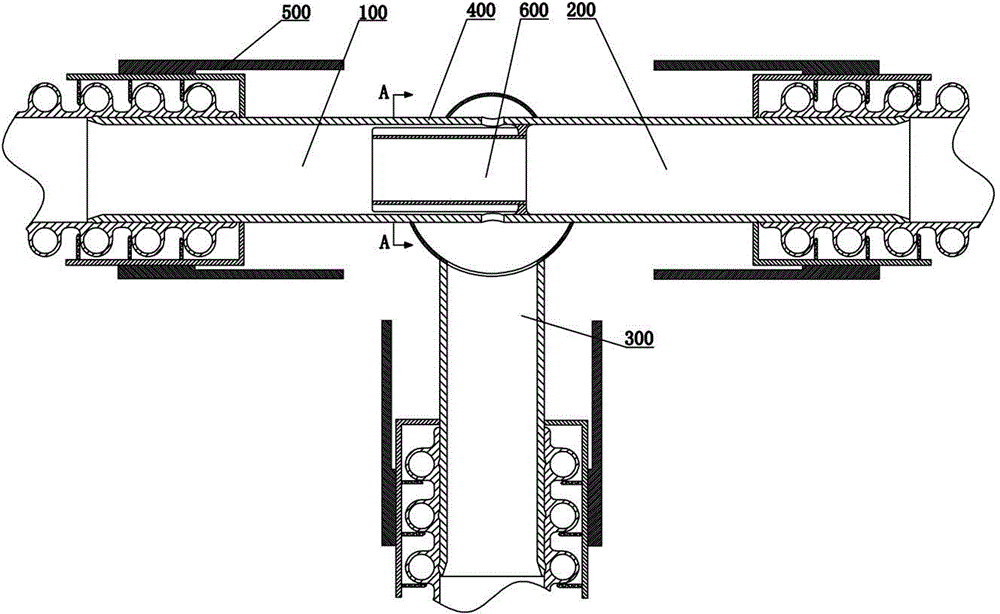

[0028] A double-wall bellows tee connection piece, comprising a first connecting pipe 100 , a second connecting pipe 200 and a third connecting pipe 300 . The first connecting pipe 100 , the second connecting pipe 200 and the third connecting pipe 300 all meet at the base 400 .

[0029] The outer diameters of the first connecting pipe 100 , the second connecting pipe 200 and the third connecting pipe 300 are all adapted to the inner diameter of the double-wall corrugated pipe. The first connecting pipe 100 , the second connecting pipe 200 and the third connecting pipe 300 are sleeved inside the double-wall corrugated pipe and adhere to the inner wall of the double-wall corrugated pipe. The inner diameter of the first connecting pipe 100 , the second connecting pipe 200 and the third connecting pipe 300 gradually decrease from the outside to the inside, and the wall thickness increases to reduce water flow resistance.

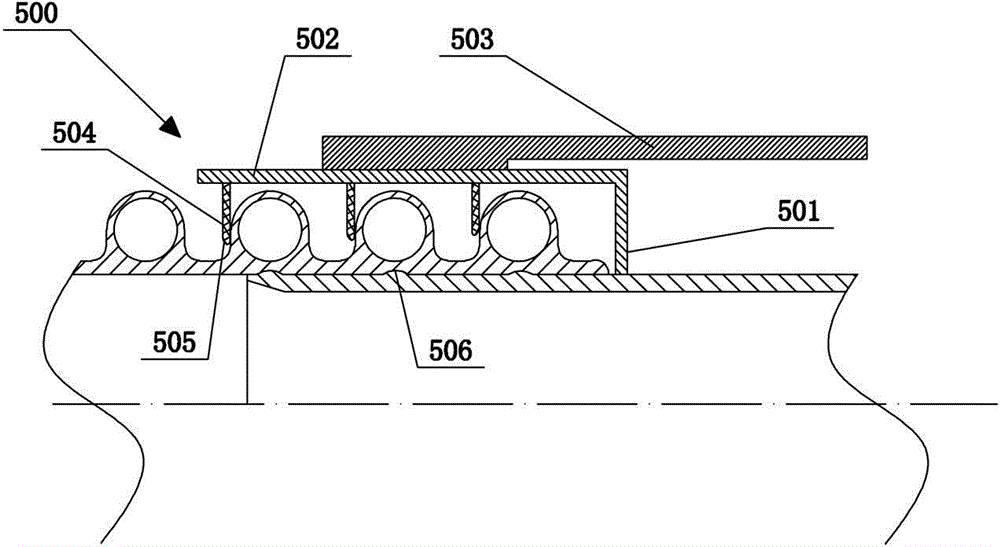

[0030] The outer walls of the first connecting pipe 100 ,...

Embodiment 2

[0043] This embodiment is suitable for placing cables.

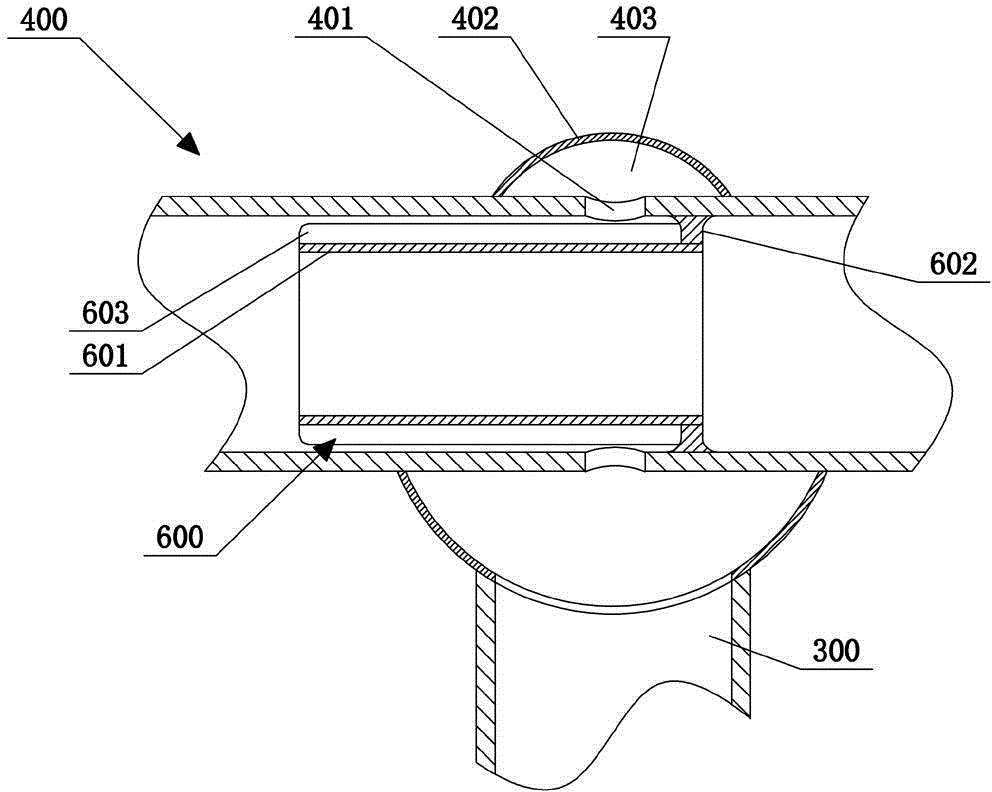

[0044] The base 400 defines a through hole 401 . The third connecting pipe 300 is connected to the through hole 401 of the base 400 .

[0045] A guiding piece 600 is sheathed inside the base 400 . The guide 600 includes a guide sleeve 601 , a guide ring 602 and a guide strip 603 . The guide sleeve 601 is a hollow cylinder, one end of the guide sleeve 601 is fixedly connected to the guide ring 602 , and the outer wall of the other end is provided with guide strips 603 at equal intervals in the axial direction. The inner wall of the guide bar 603 is fixed to the guide sleeve 601 , and the outer wall is attached to the inner wall of the base 400 . Both ends of the guide bar 603 are chamfered. The through hole 401 is located between the guide bar 603 and the guide ring 602 .

[0046] The base 400, the guide sleeve 601 and two adjacent guide strips 603 form a guide cavity.

[0047] When the cable is laid from the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com