Ballastless rail retractor

A technology for rerailers and rails, which is applied to railway car body components, equipment fixed on the rails, transportation and packaging, etc., and can solve the problem of short distances, inability to install herringbone rerailers, and inability to use inner rerailers and other issues to achieve the effect of avoiding secondary derailment, high operational safety and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

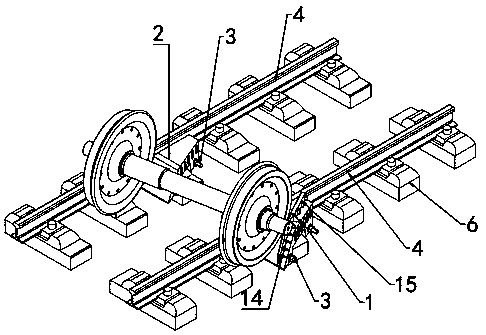

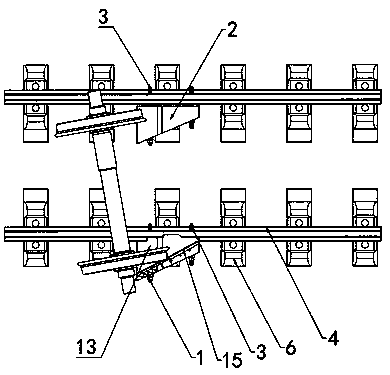

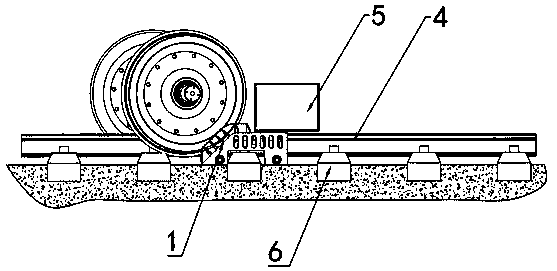

[0018] refer to Figure 1 to Figure 6 , a ballastless rail rerailer, comprising an outer rerailer 1 and an inner rerailer 2, the lower part of the outer rerailer 1 has a first positioning groove 11 matched with a sleeper 6, and the outer rerailer 1 has a first through hole 12, the tension screw 3 passes through the first through hole 12 and the outer rerailer 1 is closely installed on the outside of the rail 4, there are two first through holes 12, and they are separated from the On both sides of the first positioning groove 11, the outer rerailer 1 has a first slope surface 13, the lower part of the first slope surface 13 is inclined and the upper part is horizontal, and there is a smooth transition between the slope surface and the horizontal surface. The top of the first slope surface 13 There is a fixed guide block 14 on the top, and a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com