Adhesive tape pasting device

A gluing device and gluing surface technology, which is applied in the direction of transportation and packaging, winding strips, sending objects, etc., can solve the problems of insufficient precision, slow glue preparation speed, long time consumption, etc., achieve convenient operation and maintenance, and improve precision control , Improve the effect of gluing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

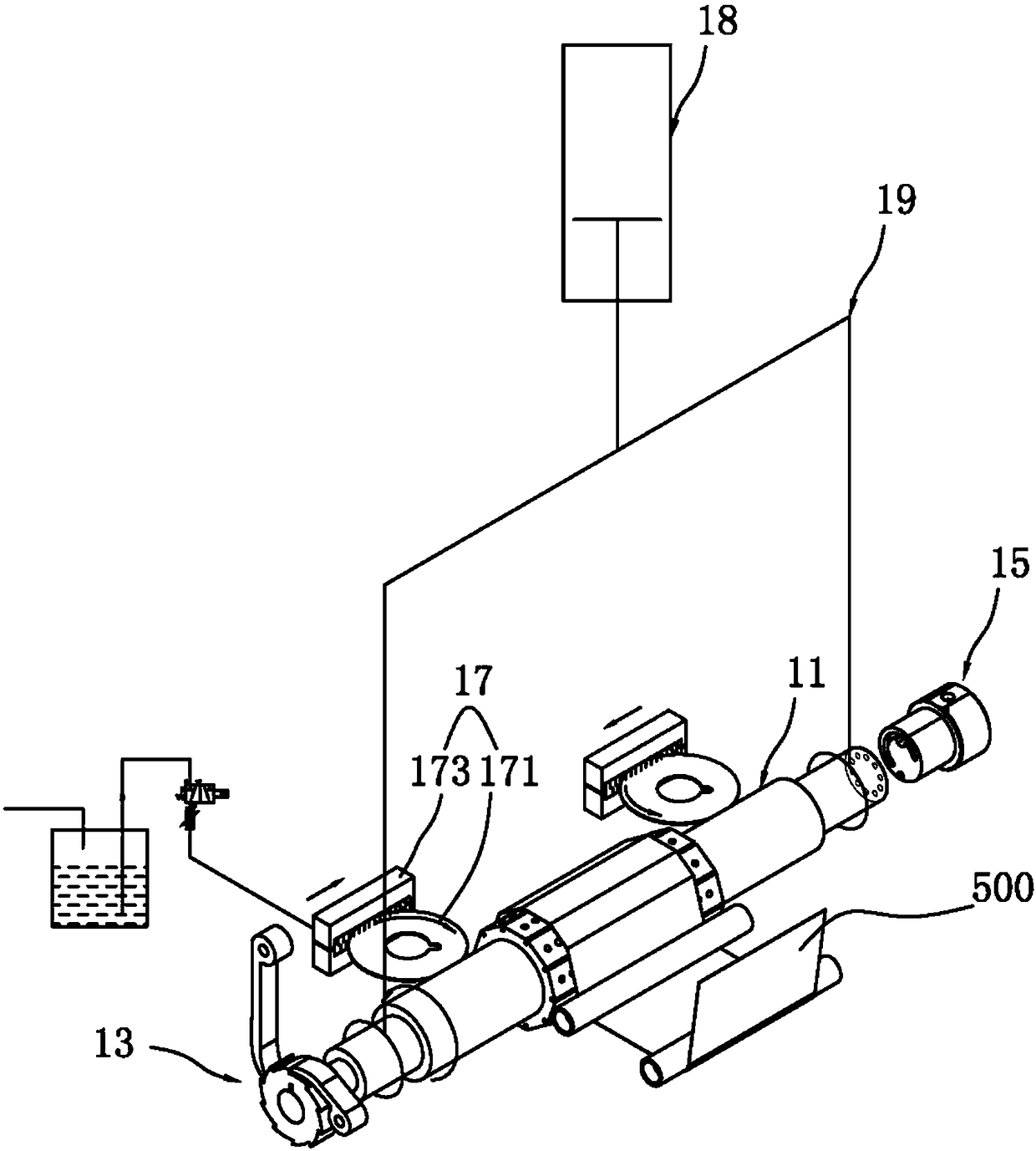

[0017] The preferred embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings of this specification.

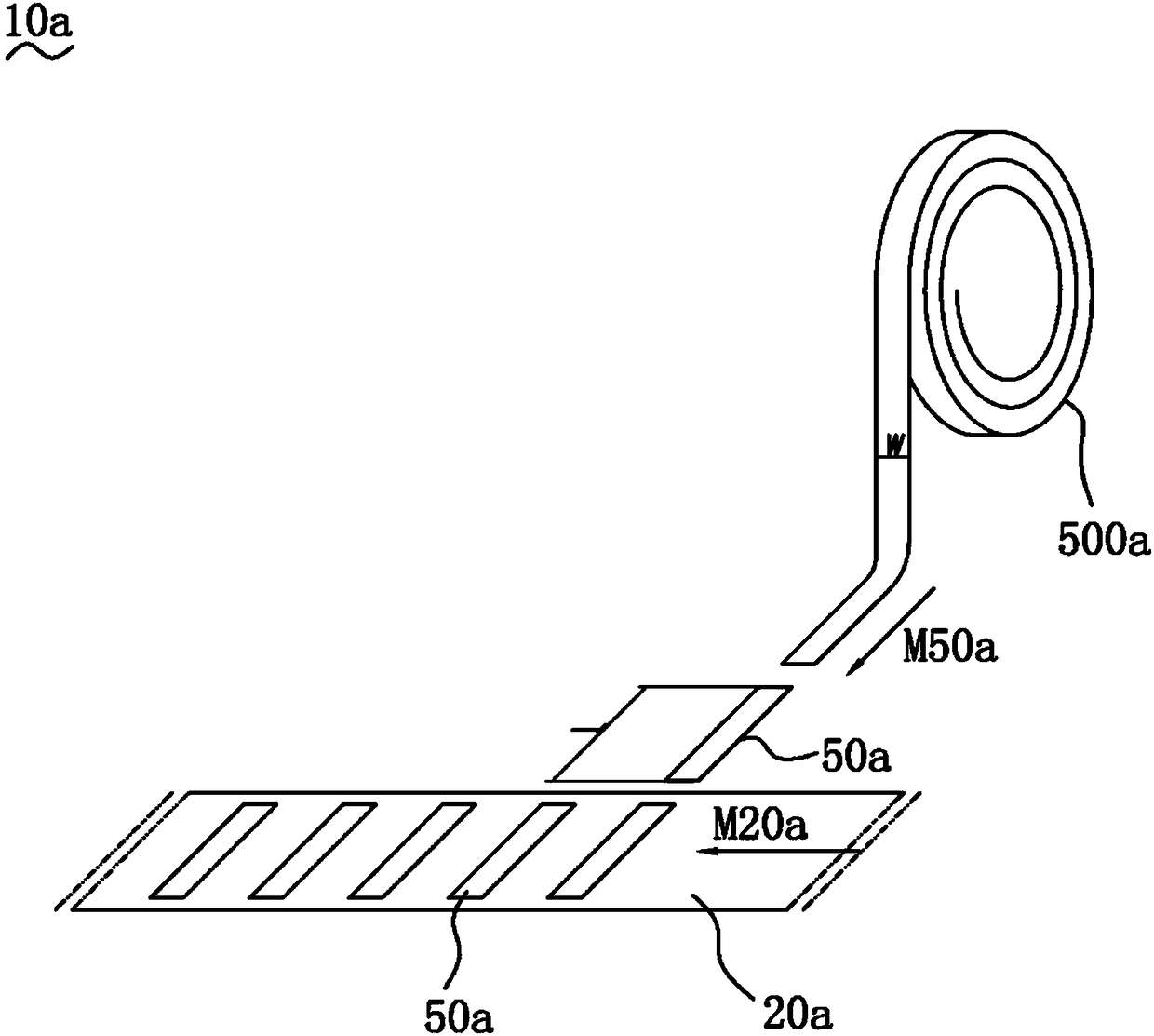

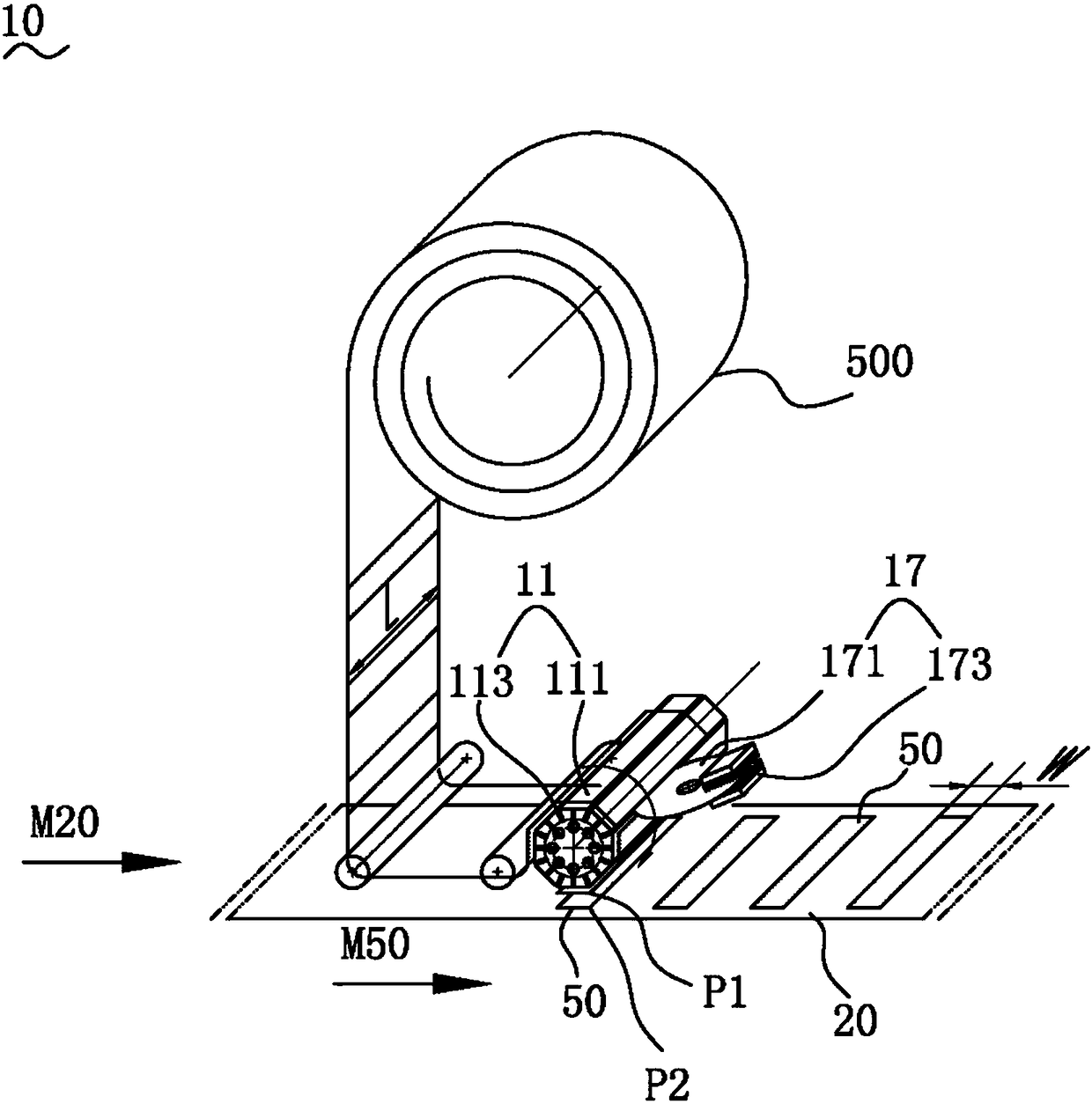

[0018] see figure 2 , figure 2 It is a schematic diagram of the working principle of the gluing device of the present invention. The present invention proposes a gluing device 10, the gluing device 10 realizes gluing by feeding the adhesive paper 500 horizontally, namely: the conveying direction of the adhesive paper 500 (that is, the arrow M50 in the figure) and the movement of the base material 20 The direction (that is, the arrow M20 in the figure) is parallel. Specifically, the single glued paper 50 is a rectangle with a set length L and width W. The cutting of a single adhesive tape 50 extends along the width direction of the adhesive tape 500 . In this way of gluing, the width W of a single glued paper 50 is adjusted by adjusting the width of the glue-carrying surface 111 on the rubber roller 11 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com