Integrated valve for inflating and deflating gas cylinders

An integrated valve, inflation and deflation technology, which is applied in the field of integrated valves, can solve the problems of large pressure sensor, no pressure detection, overpressure leakage, time-consuming and labor-intensive operation of the user, etc., and achieve the effect of reducing the overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples:

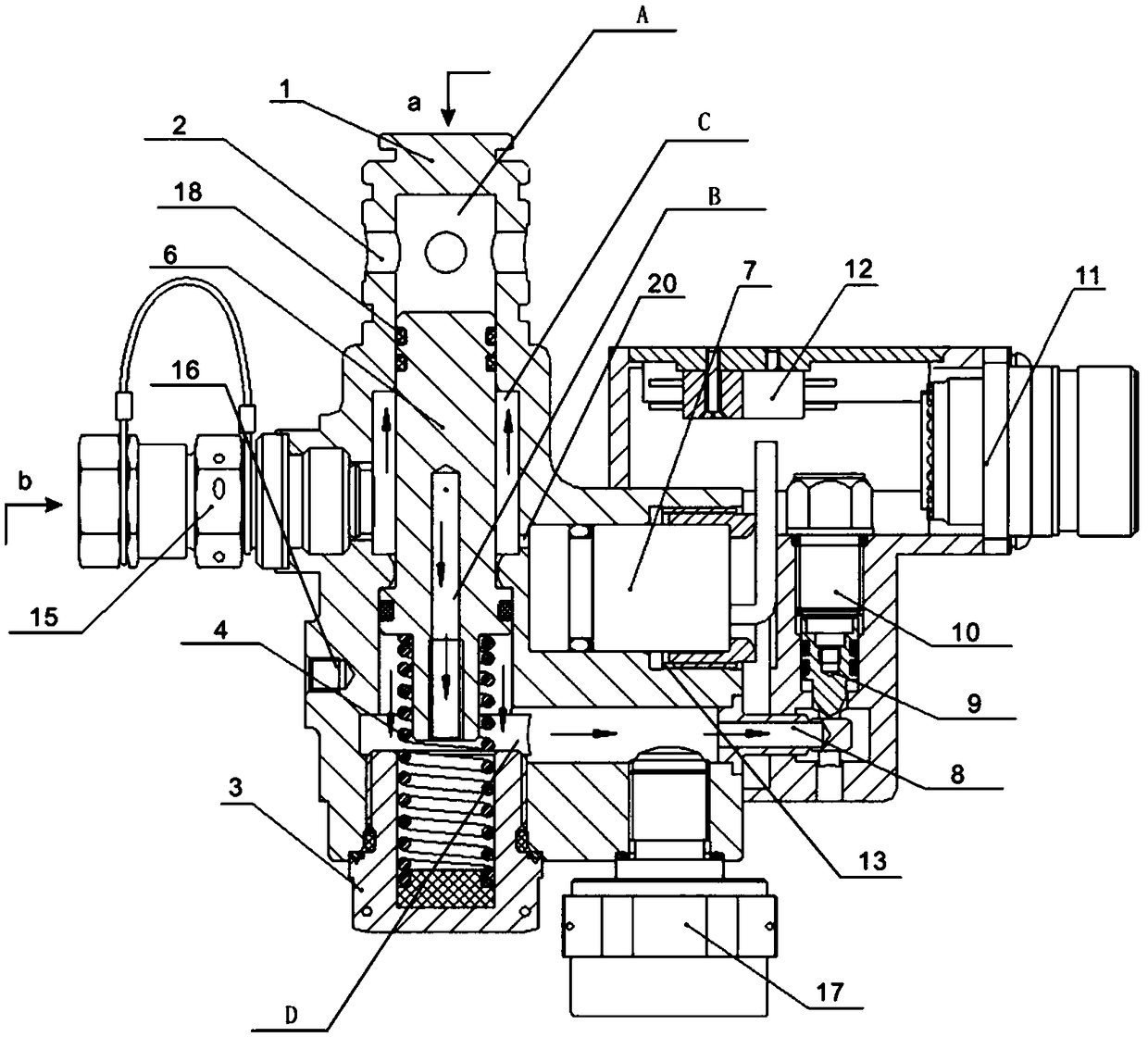

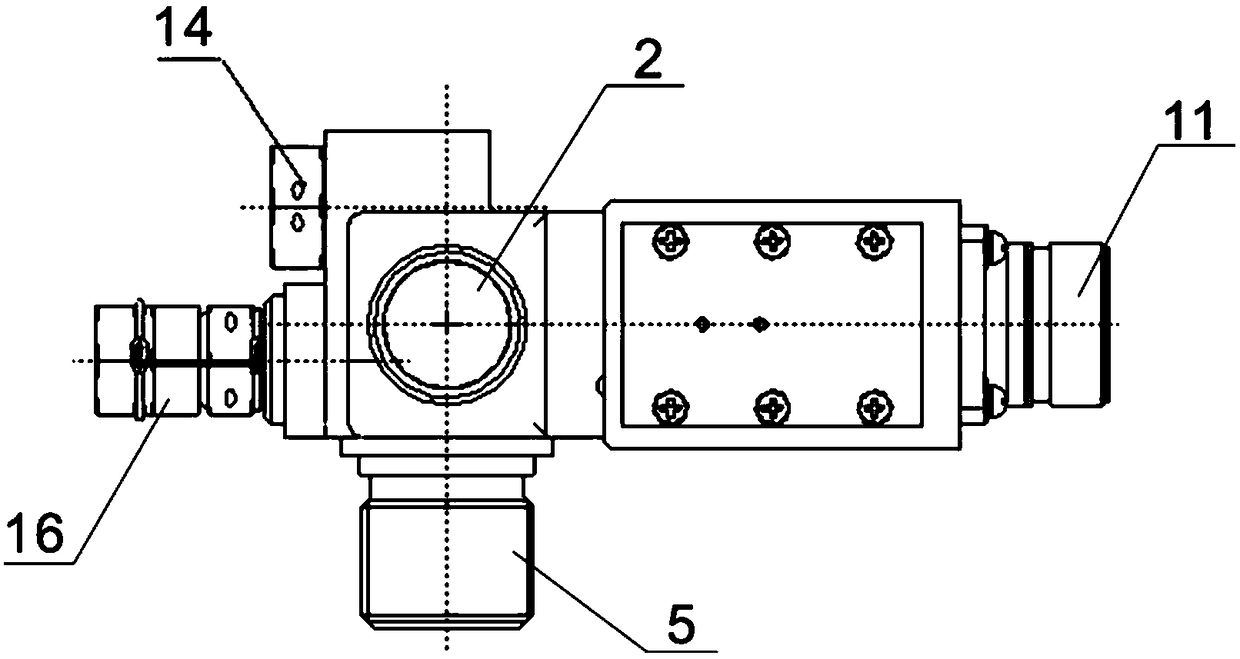

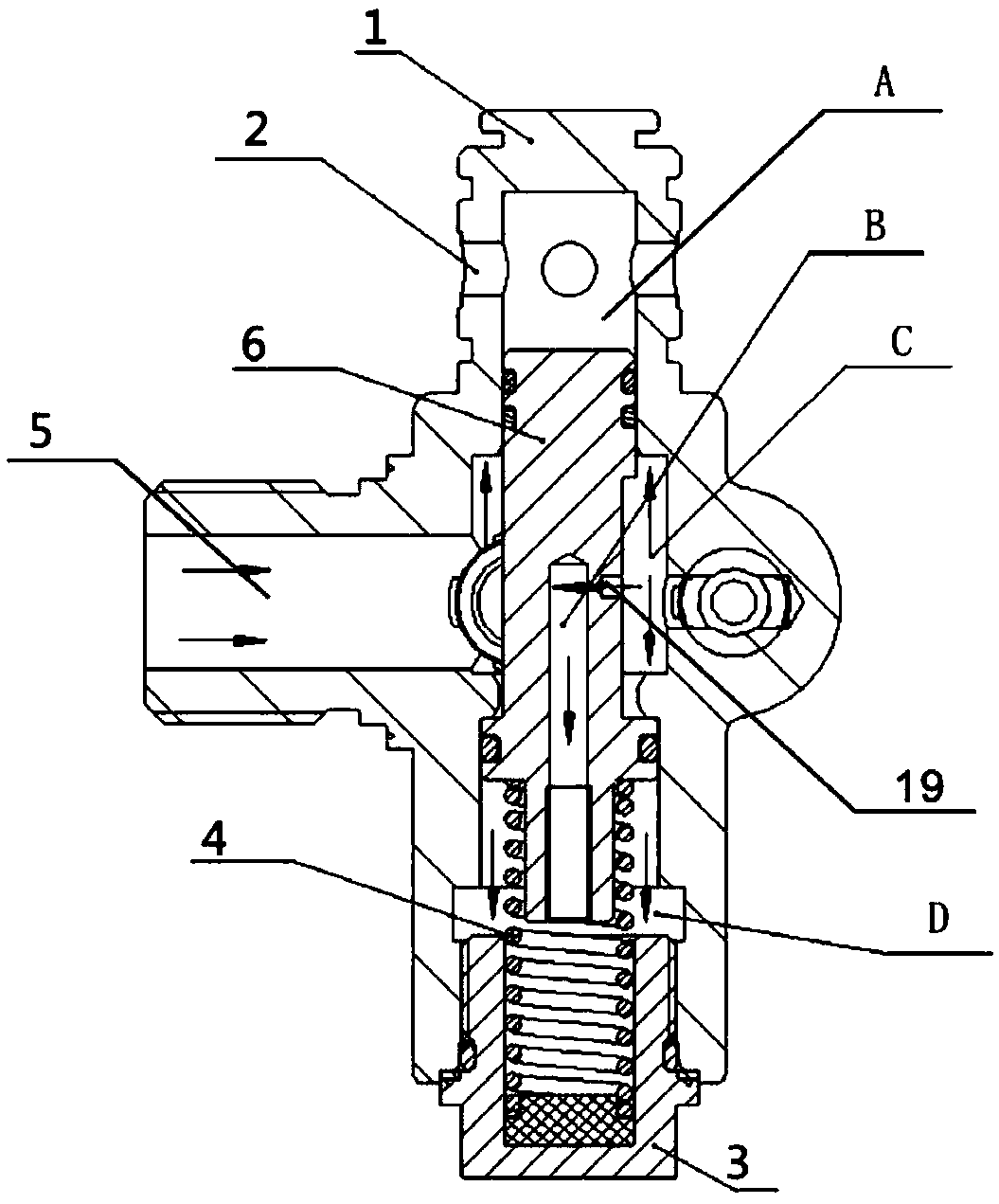

[0024] said figure 1 The arrow in is the gas flow direction when deflated in the integrated valve, image 3 The arrows in the figure indicate the gas flow direction of the integrated valve when the gas is supplied, combined with the attached Figure 1-4 The integrated valve for gas cylinder filling and deflation includes a valve body 1 and a detonating device; the valve body 1 is provided with a vertical passage, and a valve core 6 is correspondingly placed in the passage, and one end of the passage is provided It is a blocked end, and the end of the valve body 1 corresponding to the blocked end of the passage is provided with an air outlet 2 communicating with the passage, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com