Device for detecting static and dynamic strength of automobile transmission bearing

A technology of automobile transmission and dynamic strength, which is applied in the direction of measuring device, mechanical bearing test, vehicle test, etc., can solve the problem of no automobile transmission bearing strength test, etc., and achieve the effect of reliable detection method, accurate result and novel design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

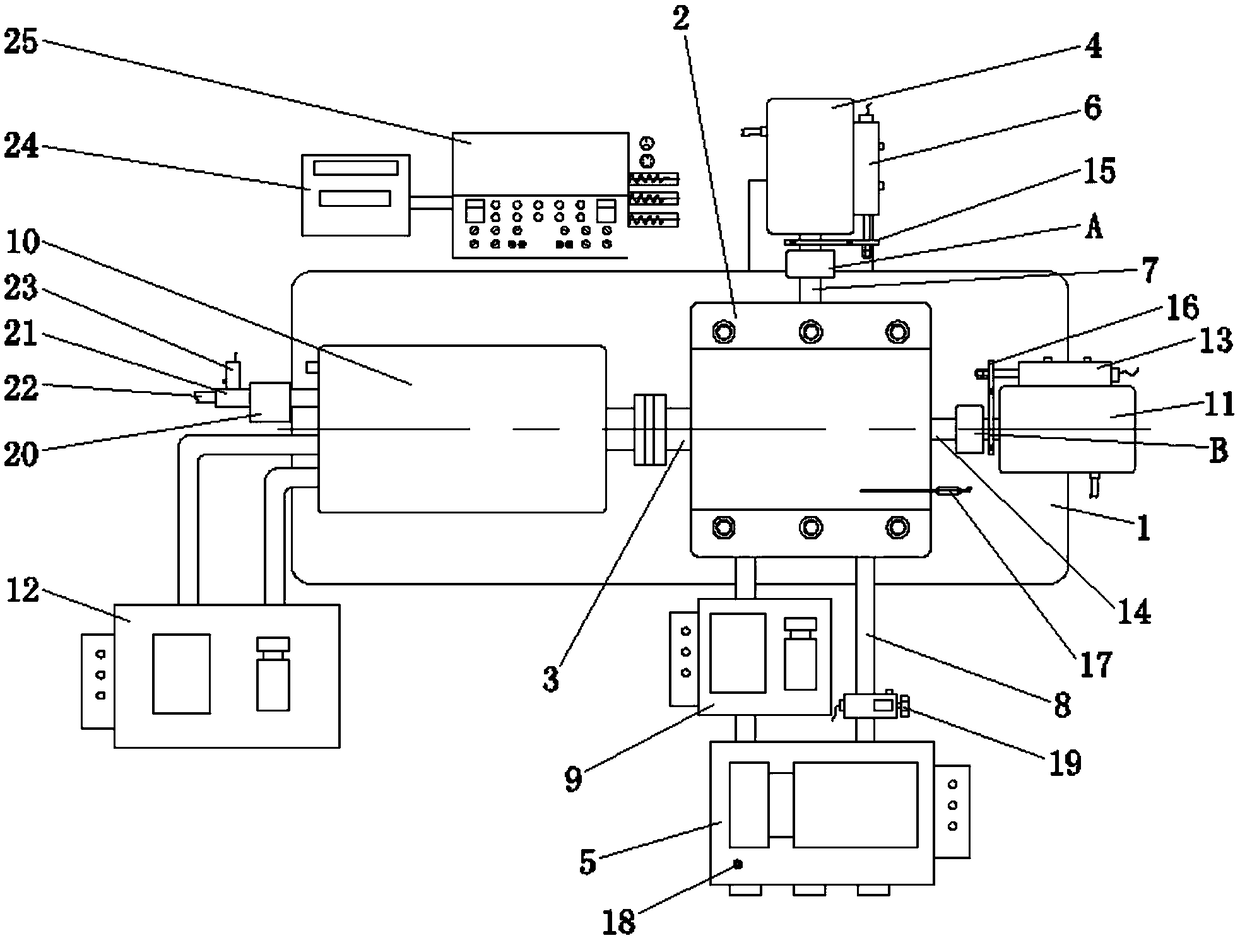

[0020] Such as figure 1 As shown, the test chamber 2 is installed on the equipment platform 1. The test chamber 2 is used to accommodate the bearing to be tested (not shown in the figure). The door of the test chamber 2 can be opened and closed, so as to take out or put in the bearing bearings. A first temperature sensor 17 is installed on the test chamber 2 , and the probe of the first temperature sensor 17 extends into the test chamber 2 . A test shaft 3 is installed in the test chamber 2, the test shaft 3 is rotatably connected with the test chamber 2, and the test shaft 3 is used for installing the bearing to be tested.

[0021] Such as figure 1 As shown, a radially loaded electric cylinder 4 is set on one side of the test cabin 2 in the front-to-back direction, and a lubricating oil heating device 5 is set on the other side. The cylinder body of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com