Apparatus and method for testing mechanical properties of fiber-reinforced composite materials during degradation

A composite material and fiber-reinforced technology, which is applied in the direction of measuring devices, applying stable tension/pressure to test the strength of materials, and analyzing materials, can solve the problem of insufficient design of environmental factors for fiber-reinforced composite materials and research work on the degradation of fiber-reinforced composite materials Limited, material mechanical properties decline and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

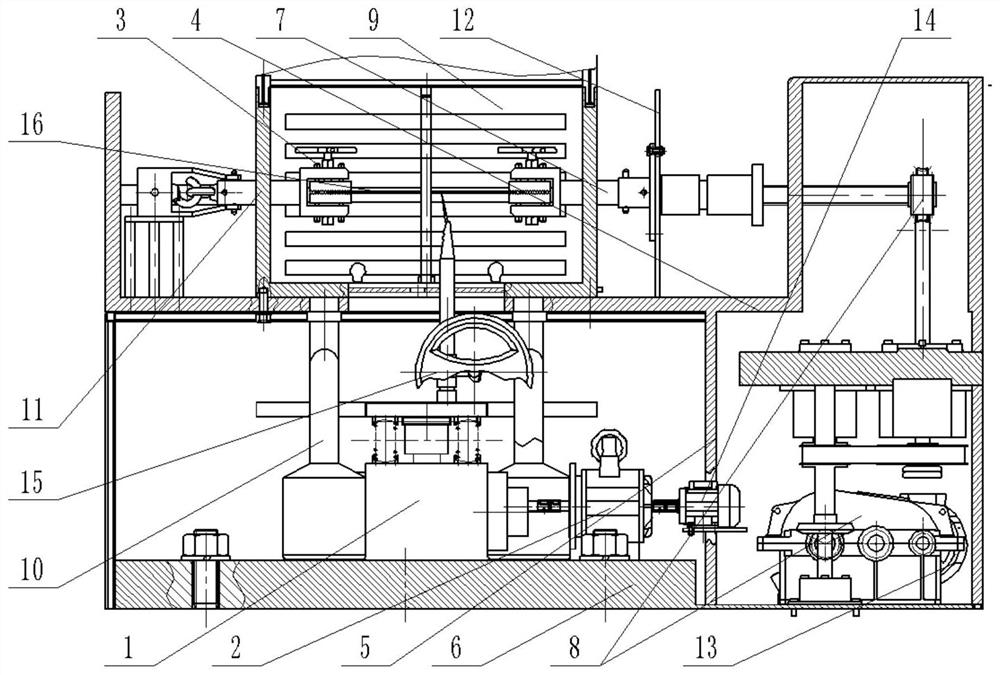

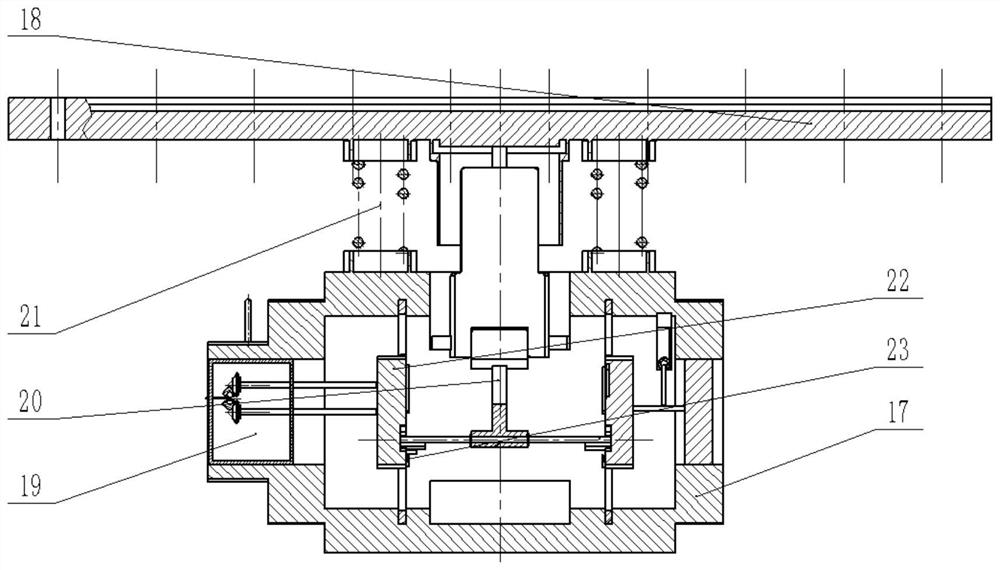

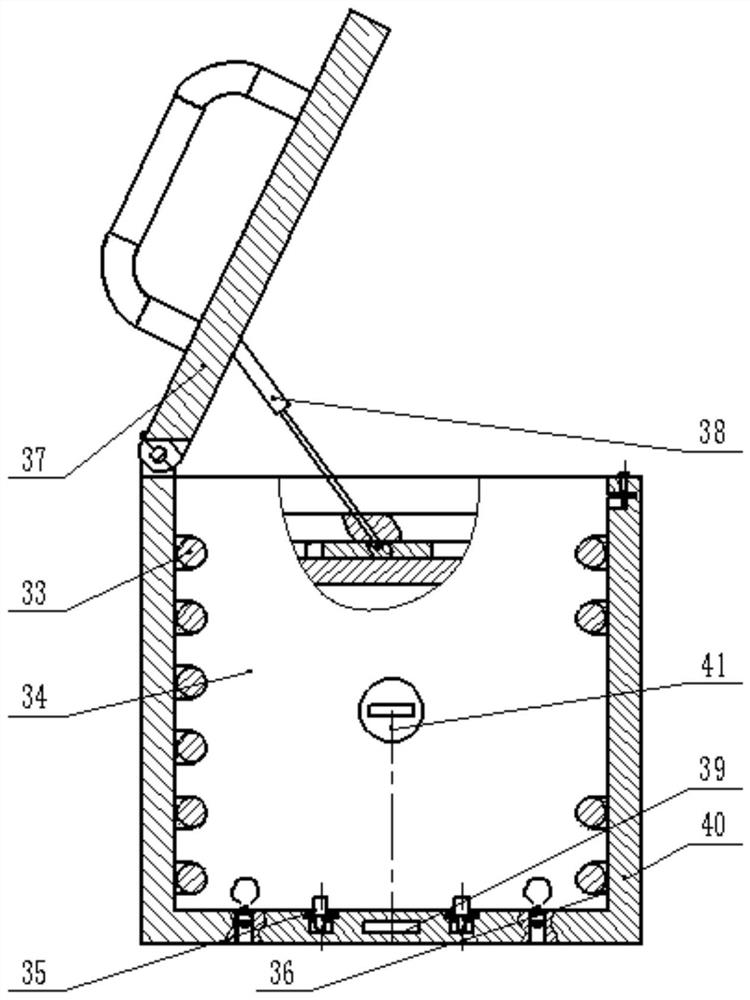

[0040] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0041] A device for testing the mechanical properties of fiber-reinforced composite materials when degraded, including a moving gear shifting exciter 1, a continuously variable transmission 2, a fixture 3, a fixed frame 4, a support 5, a bottom plate 6, a ball screw 7, a transmission system 8, Multifunctional environment box 9, ventilation device 10, vibration-absorbing fixed plug 11, screw drive plate 12, main motor 13, auxiliary motor 14, vibrating needle device 15, composite beam 16;

[0042] The lower end of the fixed frame 4 is fixed by a support 5, the bottom of the support has a bottom plate 6 connected to the ground through anchor bolts, the ball screw 7 is connected to the fixed frame 4 by threads; the transmission system 8 is supported by the fixed frame 4 , is transmitted to the ball screw 7 through the main motor 13,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com