High-precision tensile, compression and bending performance testing and analyzing equipment and high-precision tensile, compression and bending performance testing and analyzing method

A bending performance, test and analysis technology, applied in the direction of testing material strength by applying stable bending force, testing material strength by applying stable tension/pressure, and analyzing materials, can solve the problems of lack of reliable solutions and improve accuracy , high reference value, and the effect of ensuring detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

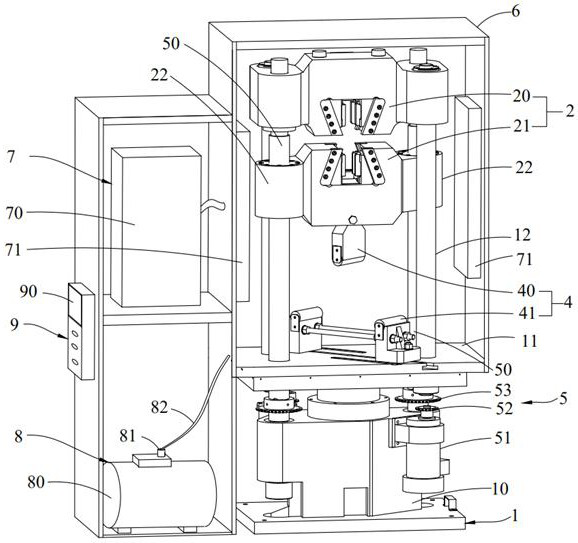

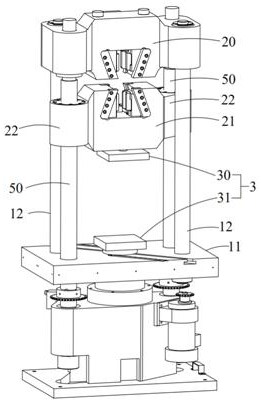

[0089] A high-precision tensile, compression, and bending performance testing and analysis equipment of this embodiment includes:

[0090] A rack 1, which includes a base 10 and a work platform 11 arranged on the base 10;

[0091] Tensile test assembly 2, used for testing tensile mechanical properties, comprising an upper clamp 20 fixed on the frame 1 and a lower clamp 21 arranged on the frame 1 movably along the Z direction;

[0092] The compression test assembly 3 is used for testing the mechanical properties of compression, which includes an upper pressing block 30 detachably arranged on the lower clamp 21 and a lower pressing block 31 detachably arranged on the working platform 11;

[0093] The bending test assembly 4 is used for testing the bending mechanical properties, and it includes an indenter 40 detachably arranged on the lower fixture 21 and a bending fixture 41 detachably arranged on the working platform 11;

[0094] The drive assembly 5 is used to drive the lowe...

Embodiment 2

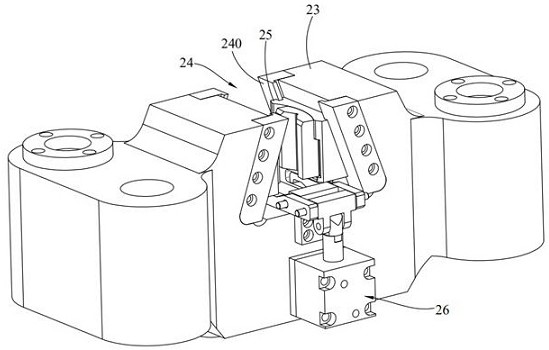

[0109] As a further improvement on the basis of Embodiment 1, in this embodiment, the upper clamp 20 and the lower clamp 21 have the same structure, and both include a clamp block 23, a wedge-shaped groove 24 opened in the clamp block 23, and a wedge-shaped groove slidably arranged in the wedge-shaped groove. The two clamping blocks 25 on the two inclined inner walls 240 of 24 and the clamp driving member 26 for driving the two clamping blocks 25 to move up and down along the inclined inner wall 240; The output rod 261 of the output rod 261 is rotatably connected to the driving connecting block 262, the first end 2630 is rotatably connected to the driving connecting block 262, and the two driving rods 263 are rotatably connected to the clamping block 23. The adapter board 264;

[0110] The bottom of the clamping block 25 is provided with a driving groove 250 , and the second ends 2631 of the two driving rods 263 respectively extend into the driving grooves 250 of the two clamp...

Embodiment 3

[0118] As a further improvement on the basis of Embodiment 1 or Embodiment 2, in this embodiment, the high-precision tensile, compressive, and bending performance testing and analysis equipment further includes a control analysis device 9, and the control analysis device 9 includes a motor 51 control module, Electric push rod 260 control module, heating control module, pressure control module and data processing module.

[0119] The motor 51 control module is electrically connected to the motor 51 , the electric push rod 260 control module is electrically connected to the electric push rod 260 , the heating control module is electrically connected to the heating device 7 , and the pressure control module is electrically connected to the pressure device 8 .

[0120] In a preferred embodiment, the control and analysis device 9 is further provided with a touch display screen 90, which is used as an input interface and a display interface of the test and analysis device.

[0121] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com