Backlight module group for light-incoming side microstructure of light guide plate

A technology of backlight module and light guide plate, which is applied in the direction of light guide, optics, optical components, etc., can solve the problems of high production cost, low production cost, and low production efficiency of injection molding, and achieve low processing cost, high processing yield, Reduces the effect of excessive luminance differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The purpose of the present invention can be achieved through the following technical solutions:

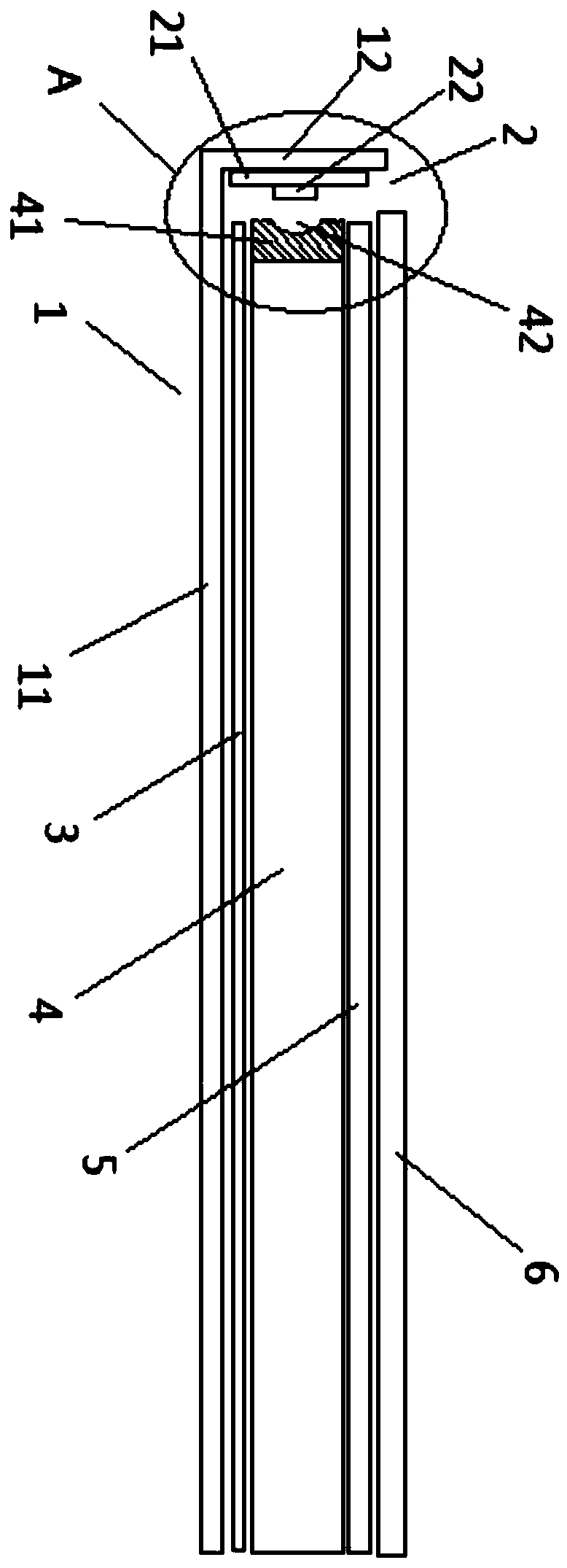

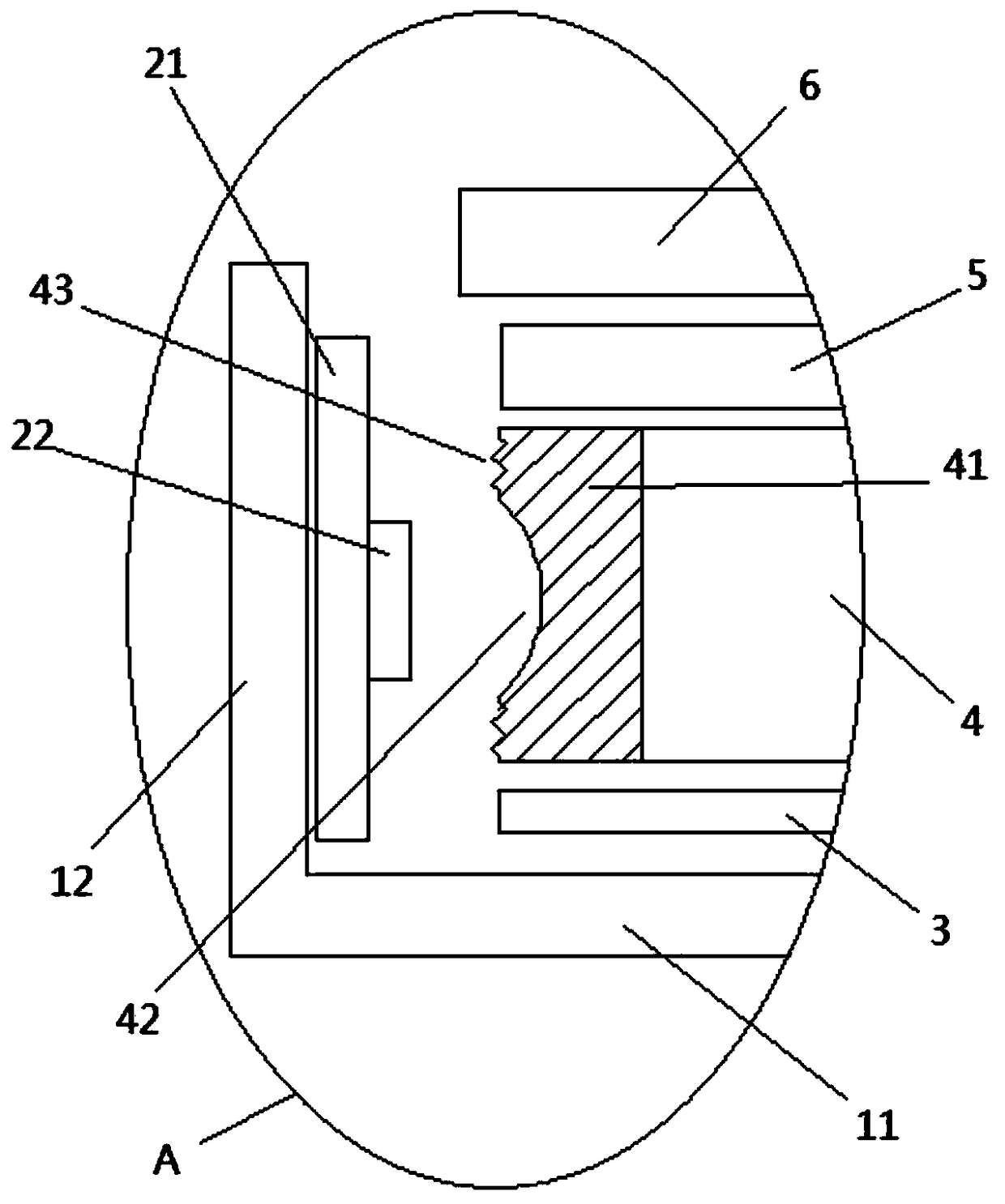

[0045] A kind of backlight module for light incident side microstructure of light guide plate, see Figure 1-3 , including a support plate 1, a light source 2, a reflective paper 3, a light guide plate 4, a diffuser plate 5, and a prism sheet 6;

[0046] The support plate 1 includes a back plate 11 and a side plate 12, the side plate 12 is arranged on one side of the back plate 11, and the side plate 12 is perpendicular to the back plate 11;

[0047] Reflective paper 3, light guide plate 4, diffuser plate 5, and prism sheet 6 are arranged on one side of the back plate 11;

[0048] A light source 2 is installed inside the side plate 12;

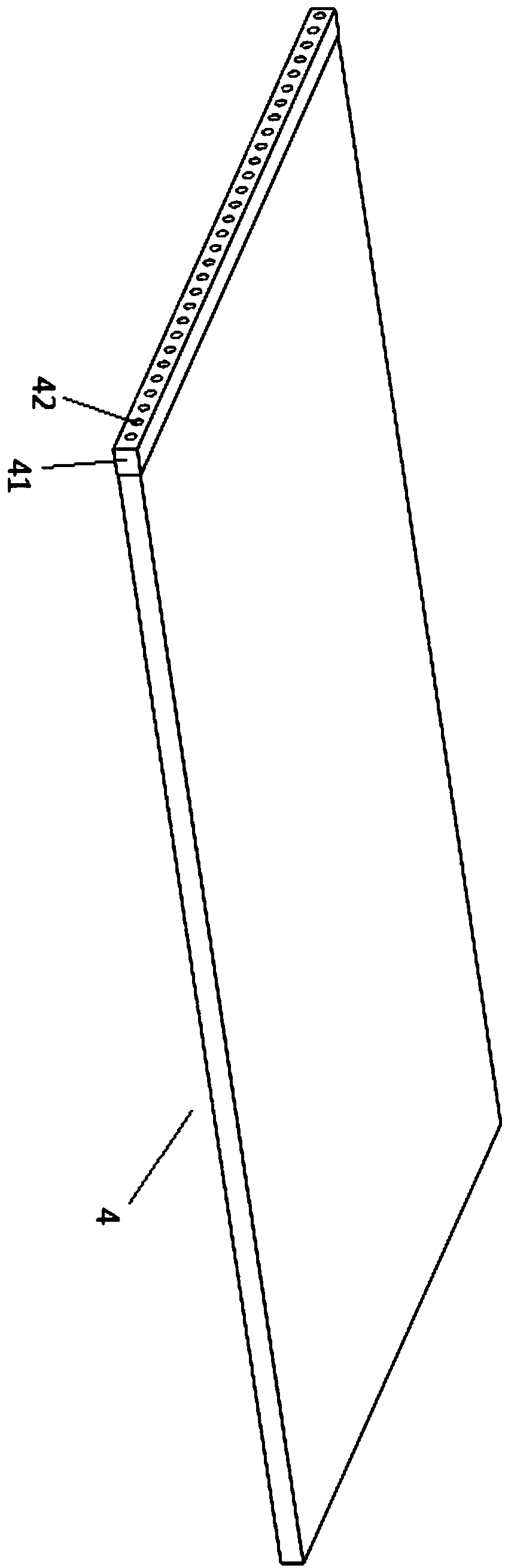

[0049] One side of the light guide plate 4 is provided with an adhesive layer 41, and the outer wall of the adhesive layer 41 is provided with a diffusion groove 42 and a sawtooth groove 43, and the diffusion groove 42 is an arc-shaped gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com