Method for vibration analysis of bi-directional functionally gradient curved shell

A technology of functional gradient and vibration analysis, applied in instrumentation, geometric CAD, calculation, etc., can solve problems such as constraints, long time required for meshing, less circumferential and axial research, etc., to ensure geometric accuracy, The effect of saving computing cost and improving computing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

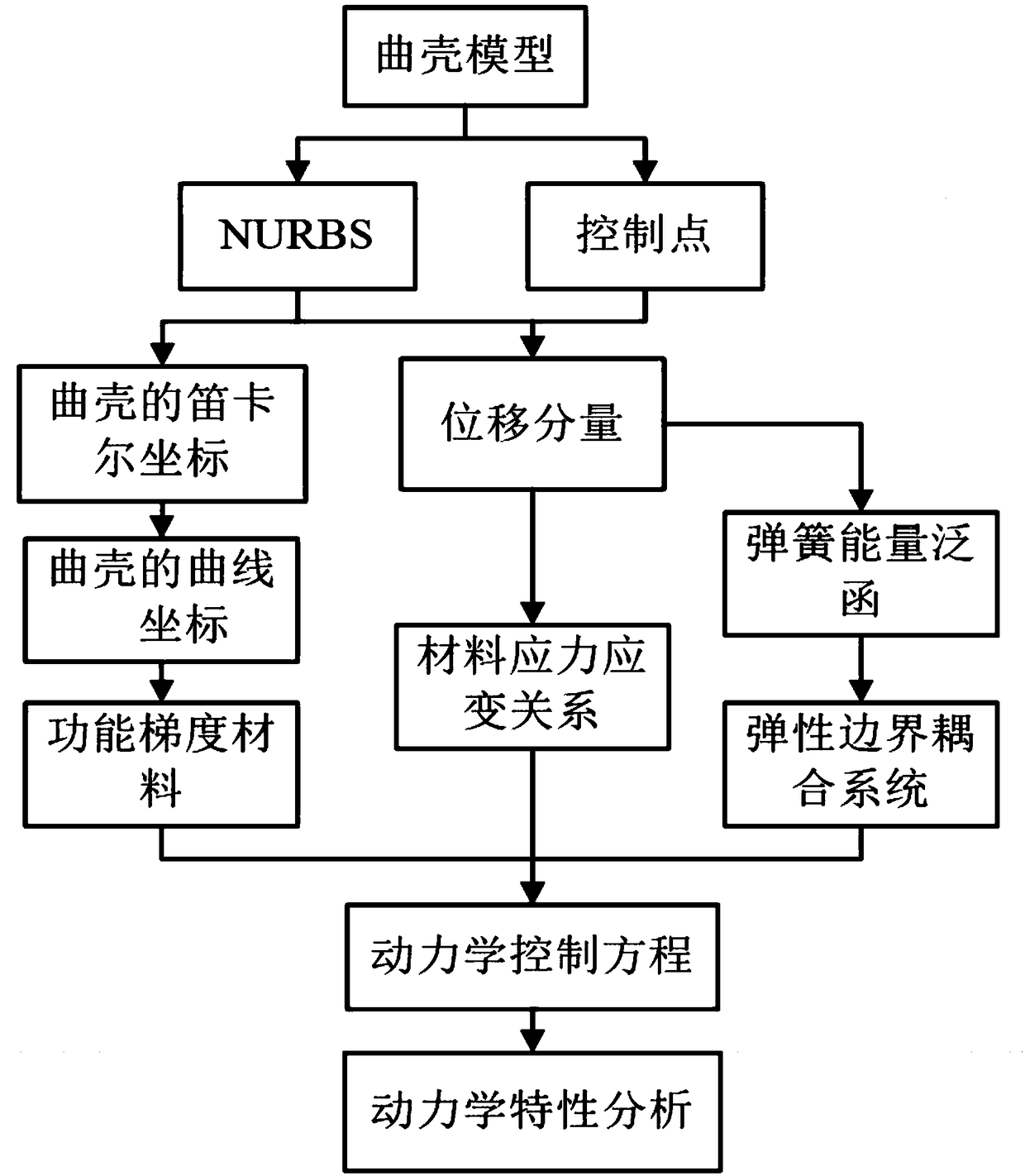

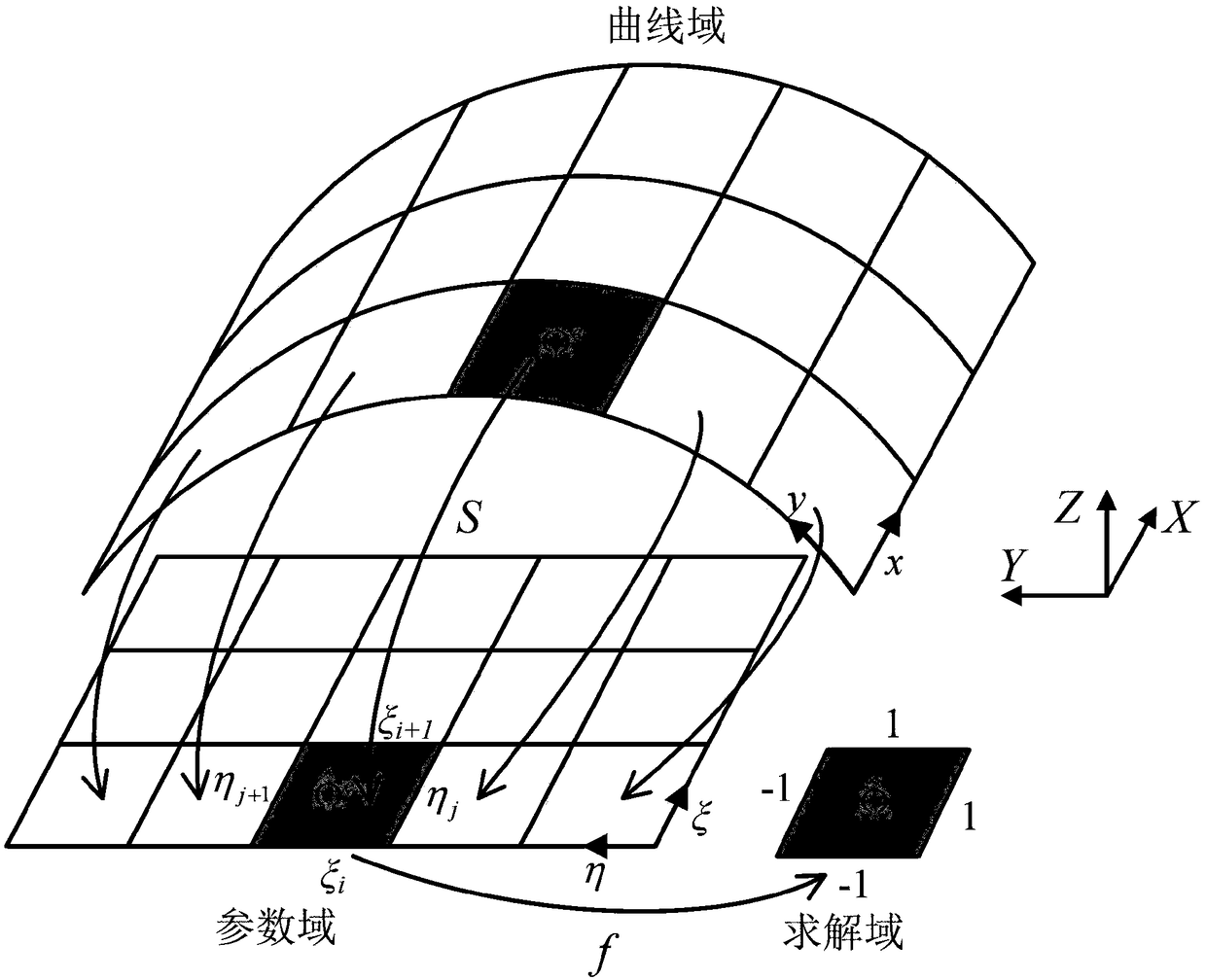

[0034] like figure 1 , 3 , Shown in 4, concrete steps of the present invention are as follows:

[0035] like figure 1 and 3 As shown, consider a 1 / 4 structure of a cylindrical shell, the radius of the structure is r=0.2m, the length is L=1m, the total thickness is h=0.02m, and the angle is θ=π / 2; and the material properties are in the axis There is a bidirectional functional gradient change in the direction and the circumference, such as Figure 4 shown. The initial material properties are considered to be aluminum i.e. E 0 =70Gpa,ρ 0 =2700kg / m 3 ,μ 0 = 0.3. Utilize the inventive method to solve it, concrete steps are as follows:

[0036] 1. Extract the control points of the curved shell and the basic parameters of the NURBS spline basis function as shown in Table 1 and Table 2 below;

[0037] Table 1

[0038]

[0039] Table 2

[0040]

[0041] Among them, i, j are parameter space spline coefficients; w i,j is the corresponding weight; B i,j for the contro...

Embodiment 2

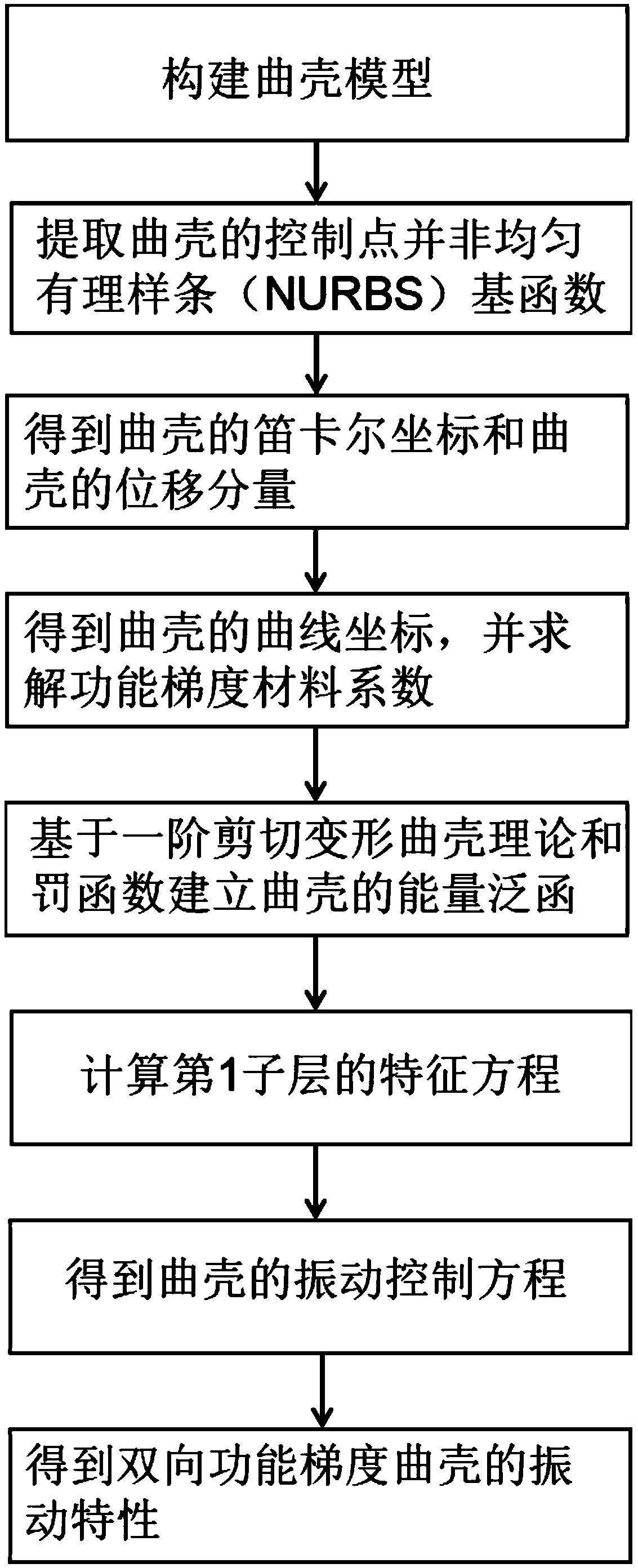

[0067] like figure 2 , 3 , Shown in 4, the specific steps of the present embodiment are as follows:

[0068] like figure 2 and 3 As shown, consider a 1 / 4 structure of a cylindrical shell, the radius of the structure is r=0.2m, the length is L=1m, the total thickness is h=0.02m, and the angle is θ=π / 2; and the material properties are in the axis There is a bidirectional functional gradient change in the direction and the circumference, such as Figure 4 shown. The initial material properties are considered to be aluminum i.e. E 0 =70Gpa,ρ 0 =2700kg / m 3 ,μ 0 = 0.3. Utilize the inventive method to solve it, concrete steps are as follows:

[0069] 1. Construct a curved shell model

[0070] 2. Extract the control points of the curved shell and the basic parameters of the NURBS spline basis function as shown in Table 1 and Table 2 below;

[0071] Table 1

[0072]

[0073] Table 2

[0074]

[0075] Among them, i, j are parameter space spline coefficients; w i,j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com