Rapid-conduction indirect liquid cooling heat radiation structure combining with micro-channel

A liquid-cooled heat dissipation and micro-channel technology, which can be used in decoration by conduction heat transfer, cooling/ventilation/heating transformation, electrical equipment structural parts, etc. It can increase the heat exchange area, improve the thermal reliability, and quickly and effectively take away the problems such as high heat dissipation capacity and insufficient heat dissipation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

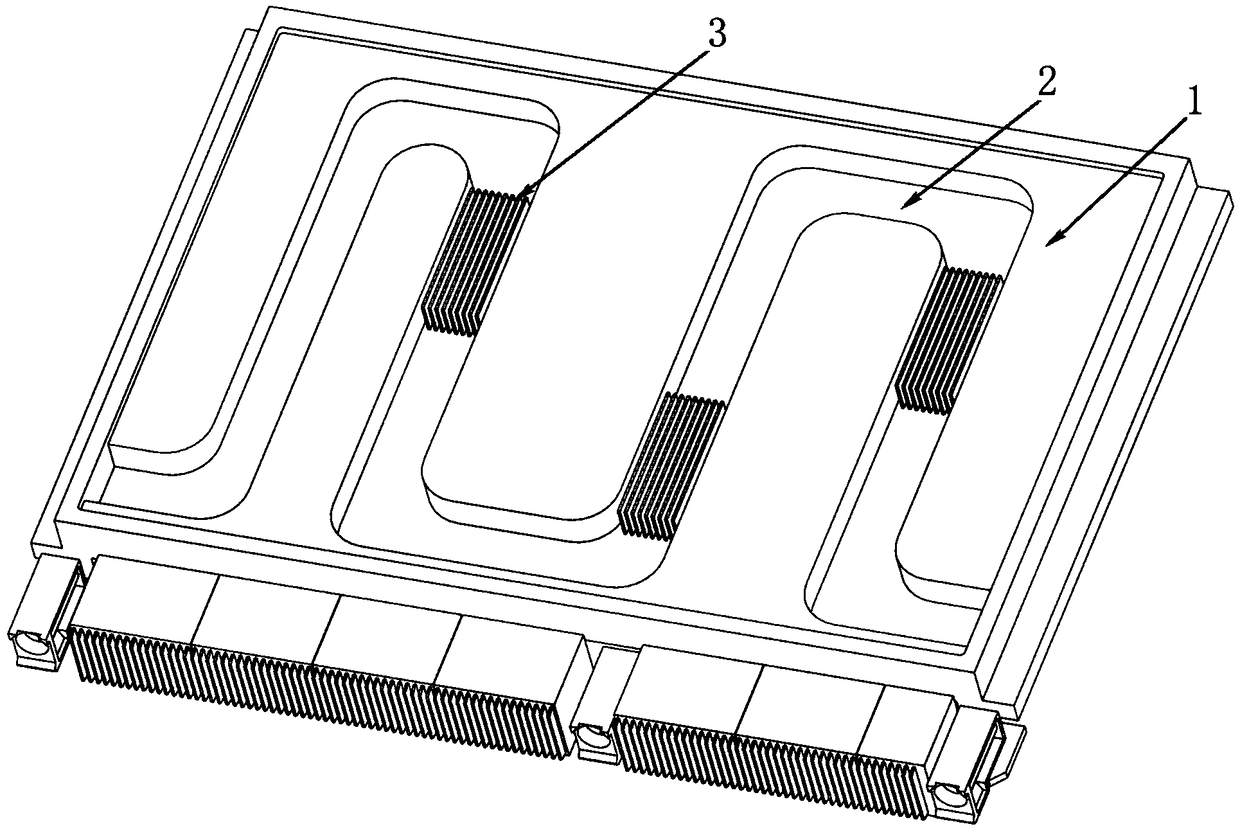

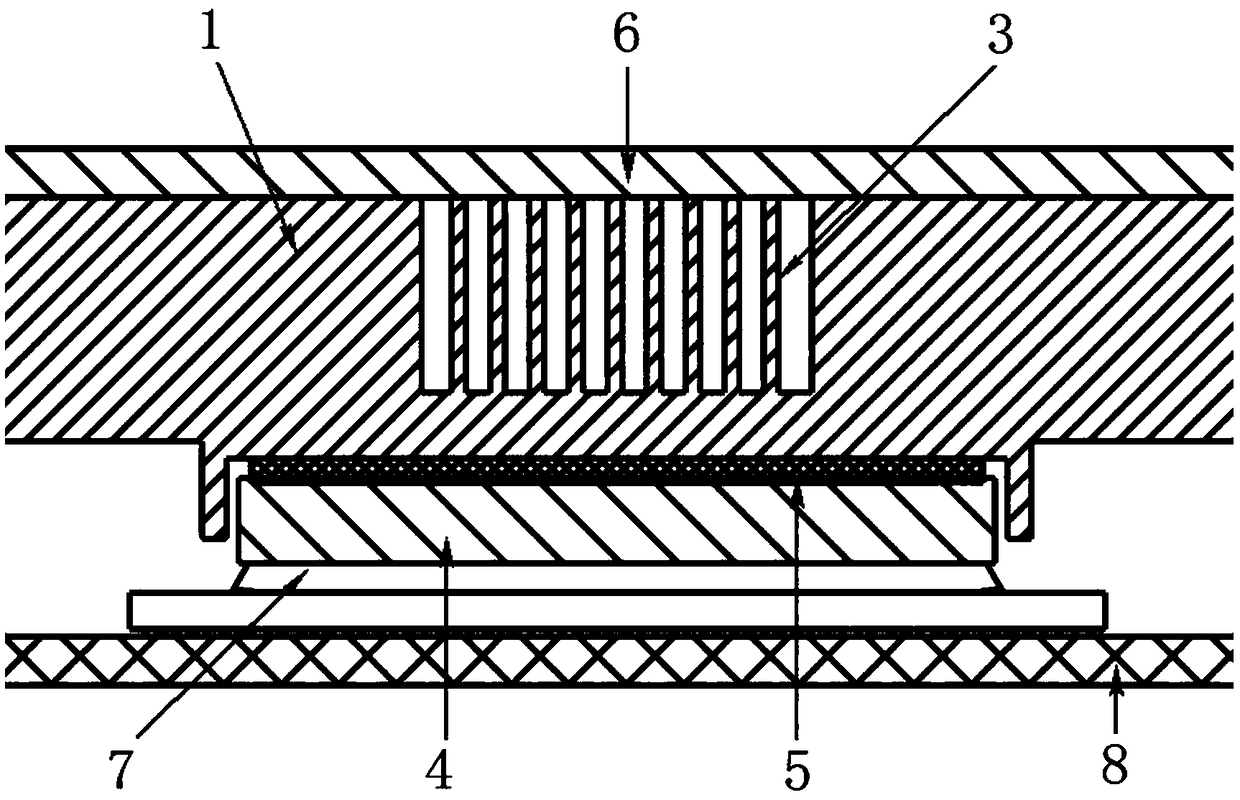

[0025] The present invention combines a rapid conduction indirect liquid cooling heat dissipation structure with micro-channels, such as figure 1 with figure 2 As shown, it includes a liquid-cooled cold plate 1, a serpentine liquid-cooled channel 2, a micro-channel cooling tooth 3, a heat-dissipating copper block 4, a heat conduction film 5, and a liquid-cooled skin 6; the liquid-cooled cold plate 1 is a board The outer end surface of the board is provided with a number of cooling fins. The liquid-cooled cold plate 1 includes a cold plate body and a liquid-cooled skin 6 that is sealed and attached to the cold plate body; a snake is set on the cold plate body. The serpentine liquid cooling channel 2 is formed by the shaped through groove; the serpentine liquid cooling channel 2 adopts a rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com