Scintillator

A scintillator and scintillator layer technology, applied in the field of scintillators, can solve the problems of non-airtightness and poor barrier layer, and achieve the effect of thin quality and maintaining performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

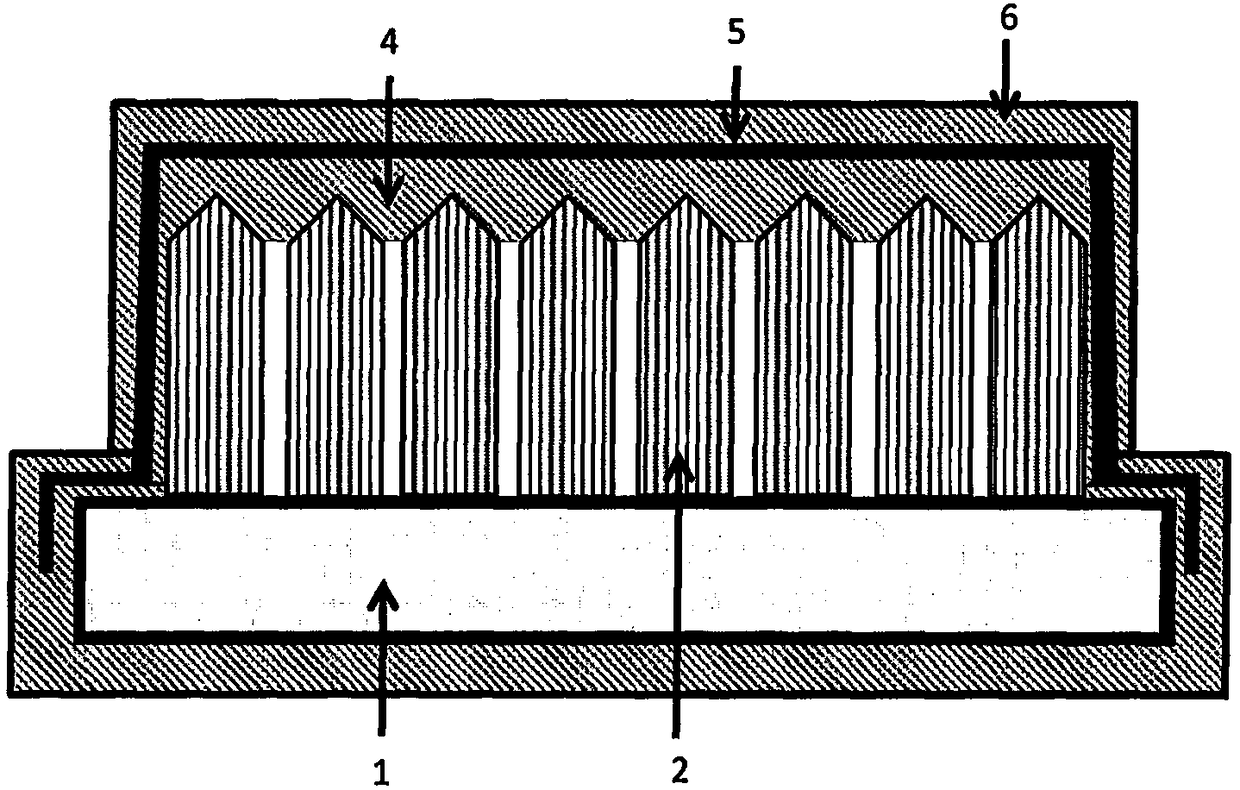

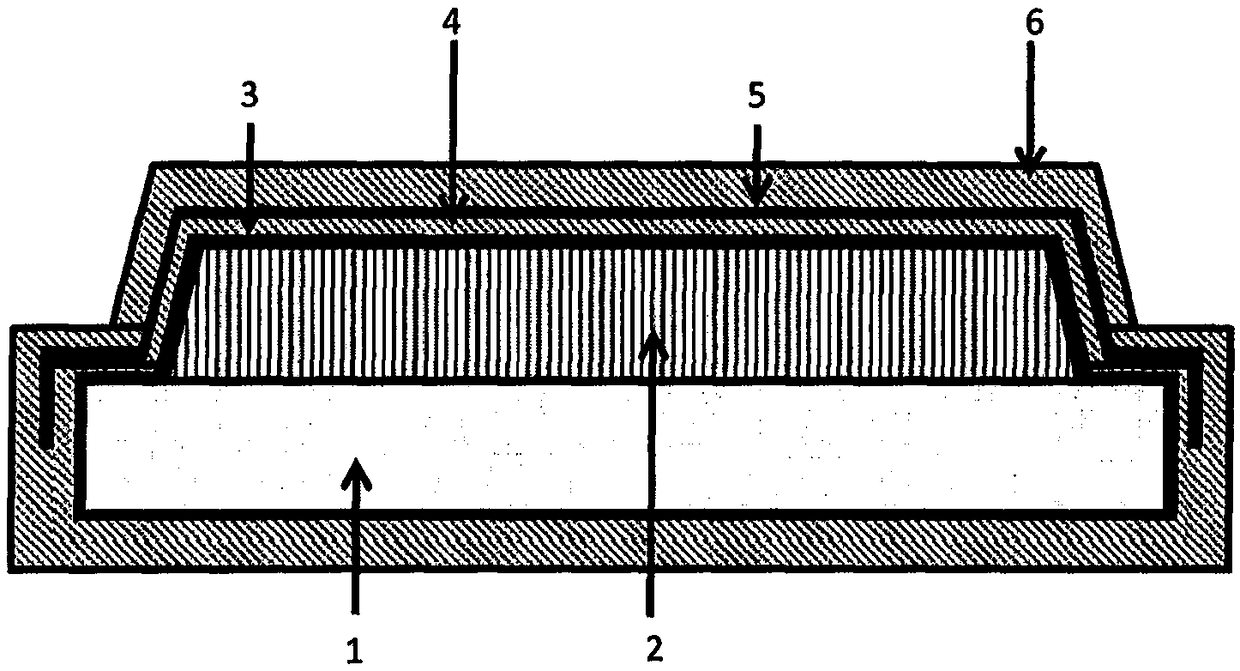

[0038] The invention relates in a first aspect to an improved scintillator for X-rays according to claim 1 .

[0039] The scintillator of the present invention includes a substrate layer. In one example, the ply is selected from aluminum, fiber optic and carbon. It should be noted that, as shown in the figure, in the case of a fiber optic plate, the scintillator layer is preferably placed on the plate, while in the case of aluminum and carbon plates, the scintillator is preferably placed below the plate. Aluminum is preferred if relatively high energy x-rays need to be detected, and carbon is preferred when relatively low energy x-rays need to be detected. Carbon also matches well with glass substrates.

[0040] The substrate or plate typically has a thickness of 0.3mm-100mm. In one example, the aluminum plate has a thickness of 0.3mm-1.0mm, the fiber optic plate has a thickness of 1mm-4mm, and the carbon plate has a thickness of 0.5mm-2.0mm. In one example, the plate prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com