Personalized customized orthopaedic insole and manufacturing method thereof

An insole and orthopedic technology, applied in the field of orthopedic insole, can solve the problems of different sizes, shapes and needs, and achieve the effect of relieving foot pain and maintaining foot stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

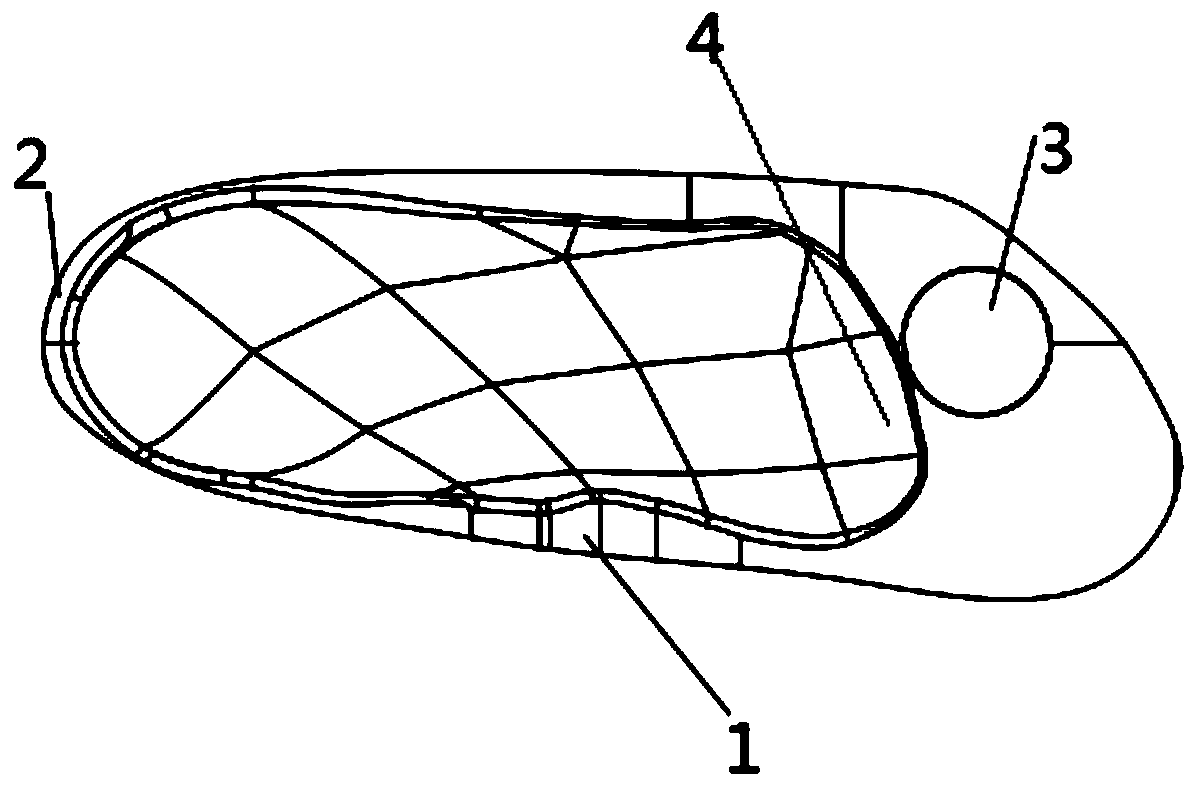

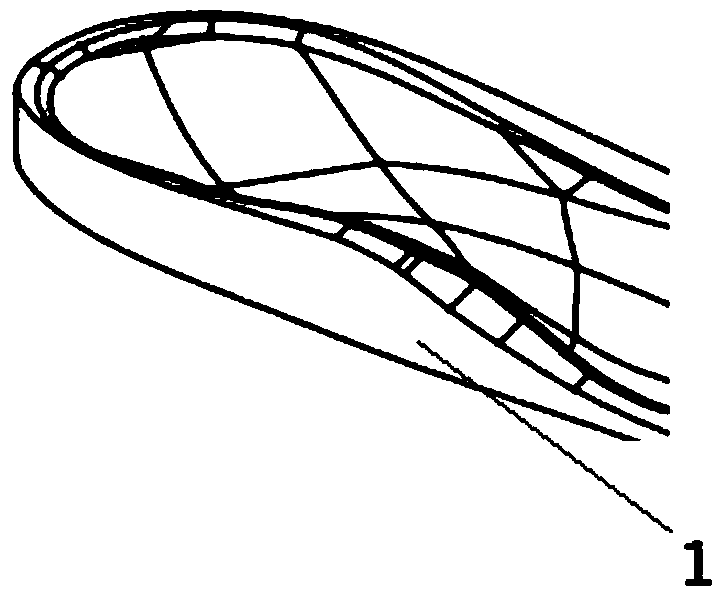

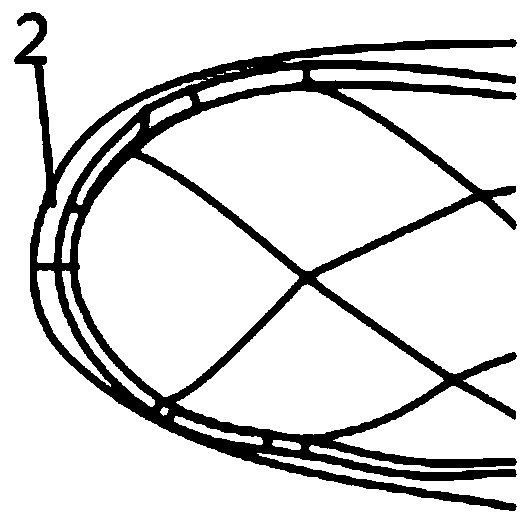

[0026] Such as figure 1 As shown, the personalized orthopedic insole includes: arch support 1, heel cup 2, decompression hole 3 and skin 4, the heel cup 2 is located behind the arch support 1, and the decompression hole 3 is located On the arch support 2, the decompression hole 3 corresponds to the position of the affected part, and the veneer 4 is located above the arch support 1 and the heel cup 2. Further, the decompression hole 3 is a circular or elliptical structure.

[0027] Further, the edges of the decompression holes 3 are arc-shaped and smooth.

[0028] Further, there are one or more decompression holes 3 .

Embodiment 2

[0030] Personalized customized orthopedic insoles, including: arch support 1, heel cup 2, decompression hole 3 and skin 4, the heel cup 2 is located behind the arch support 1, and the decompression hole 3 is located behind the arch support 2, the decompression hole 3 corresponds to the position of the affected part, and the veneer 4 is located above the arch support 1 and the heel cup 2, further, the decompression hole 3 is a circular or elliptical structure.

[0031] Further, the edges of the decompression holes 3 are arc-shaped and smooth.

[0032] Further, there are one or more decompression holes 3 .

[0033] Further, the said heel cup 2 is a cup structure surrounding the heel.

[0034] Further, the height of the heel cup 2 can be adjusted according to requirements.

[0035] Further, the arch support 1 is a curved structure with individual design.

[0036] Further, the veneer 4 is an arc-shaped structure that matches the size of the sole of the foot.

[0037] Further, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com