Mobile blowing-sucking type modular dust removal system

A dust removal system and modular technology, applied in the fields of smoke and dust removal, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of secondary dust, endangering physical and mental health, and difficult to purify.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

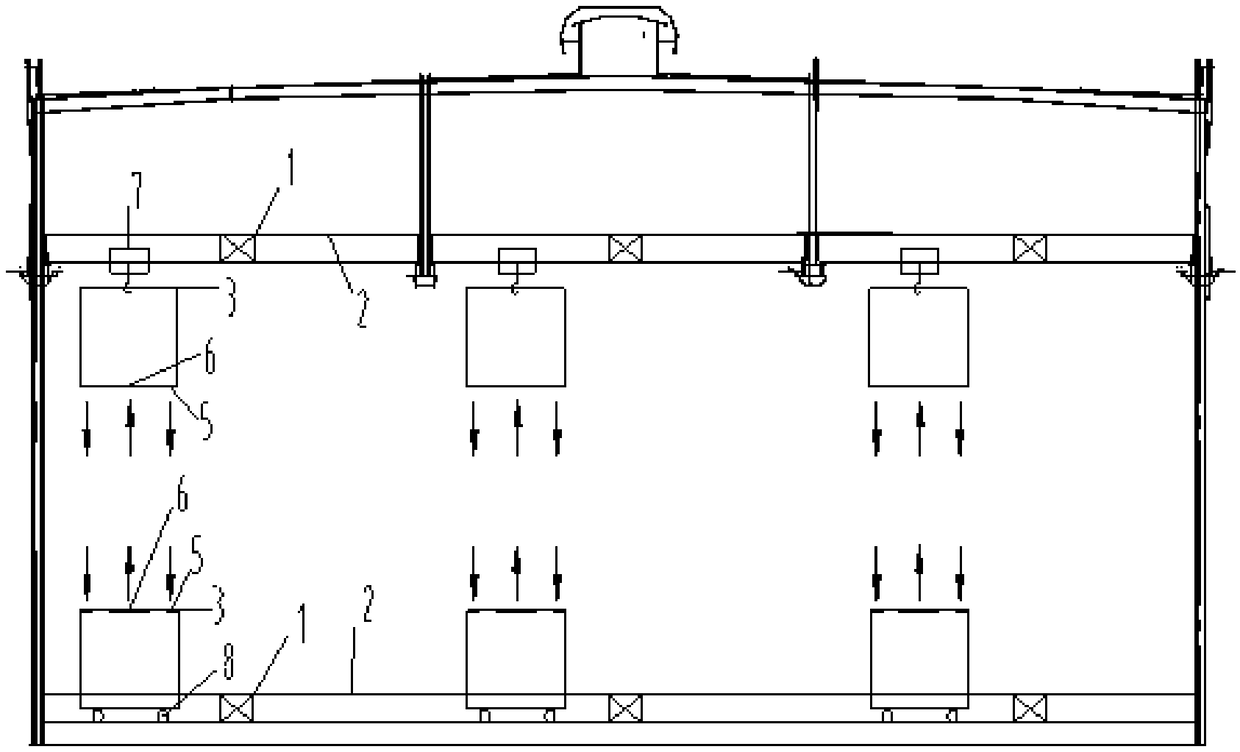

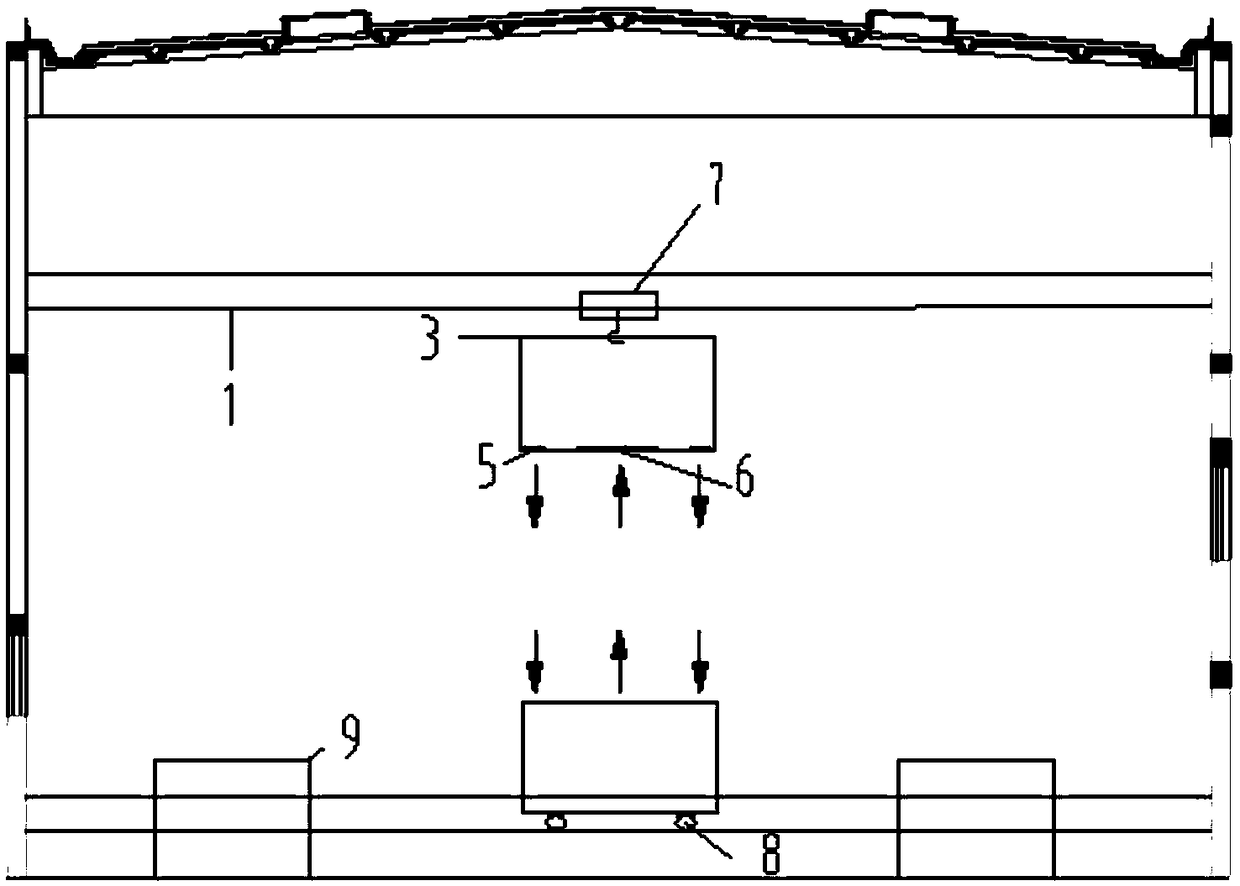

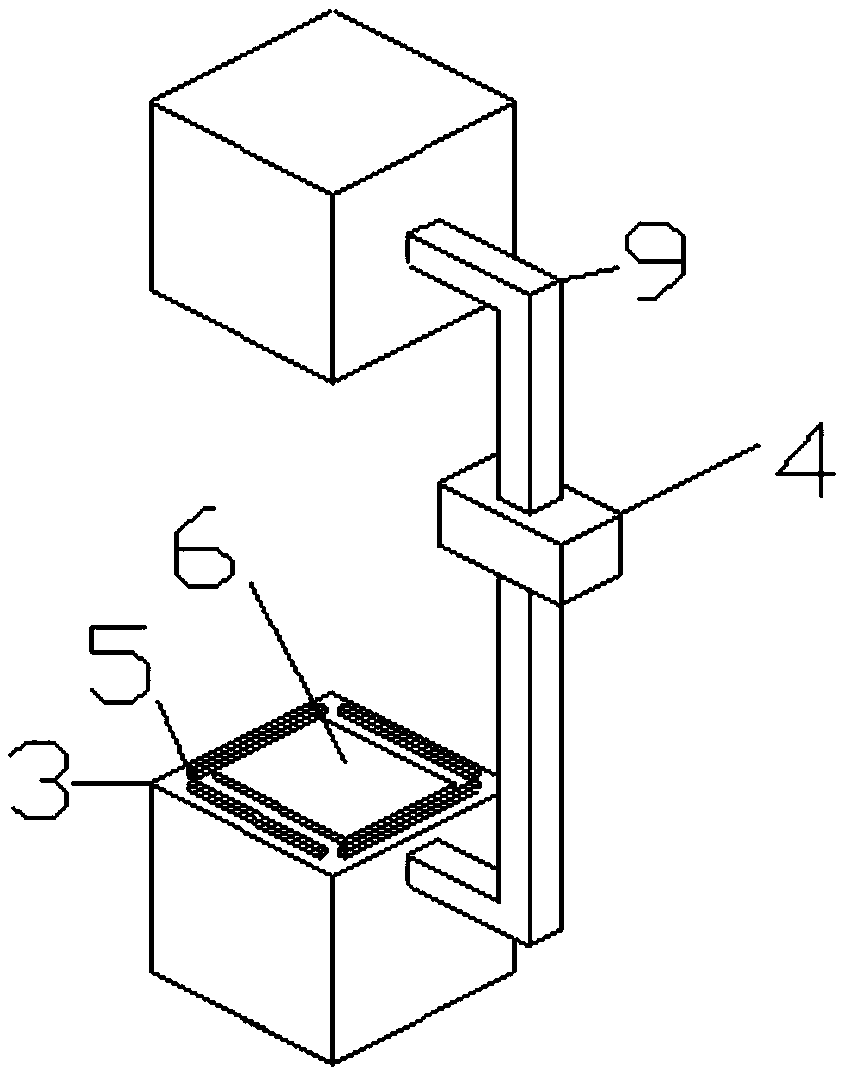

[0021] Such as Figure 1-5 As shown, it is a mobile blowing and suction modular dust removal system provided in this embodiment, which includes three sets of two interconnected mobile blowing and suction modular dust collectors 3 arranged horizontally in sequence, so that the corresponding two A mobile blowing-suction modular dust collector 3 always maintains an up-and-down synchronous mobile driving component at the same horizontal position and a pulsation intelligent central control system 4 for controlling the up-down synchronous mobile driving component and the mobile blowing-suction modular dust collector 3 . Each group of mobile blowing and suction modular dust collectors 3 shares a central control system 4, which is connected with the mobile blowing and suction modular dust collectors 3 by data control lines, and the data control lines are passed through hoses 9 for protection .

[0022] The up and down synchronous mobile crane assembly includes two sets of trusses arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com