British standard plug of novel riveting mode

A new type of riveting technology, applied in the direction of connection, electrical components, circuits, etc., can solve problems such as falling off, terminal pieces cannot be tightly pressed and connected, and it is difficult to ensure uniform deformation and expansion of riveted parts, so as to avoid loosening up and down, improve conductive stability, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

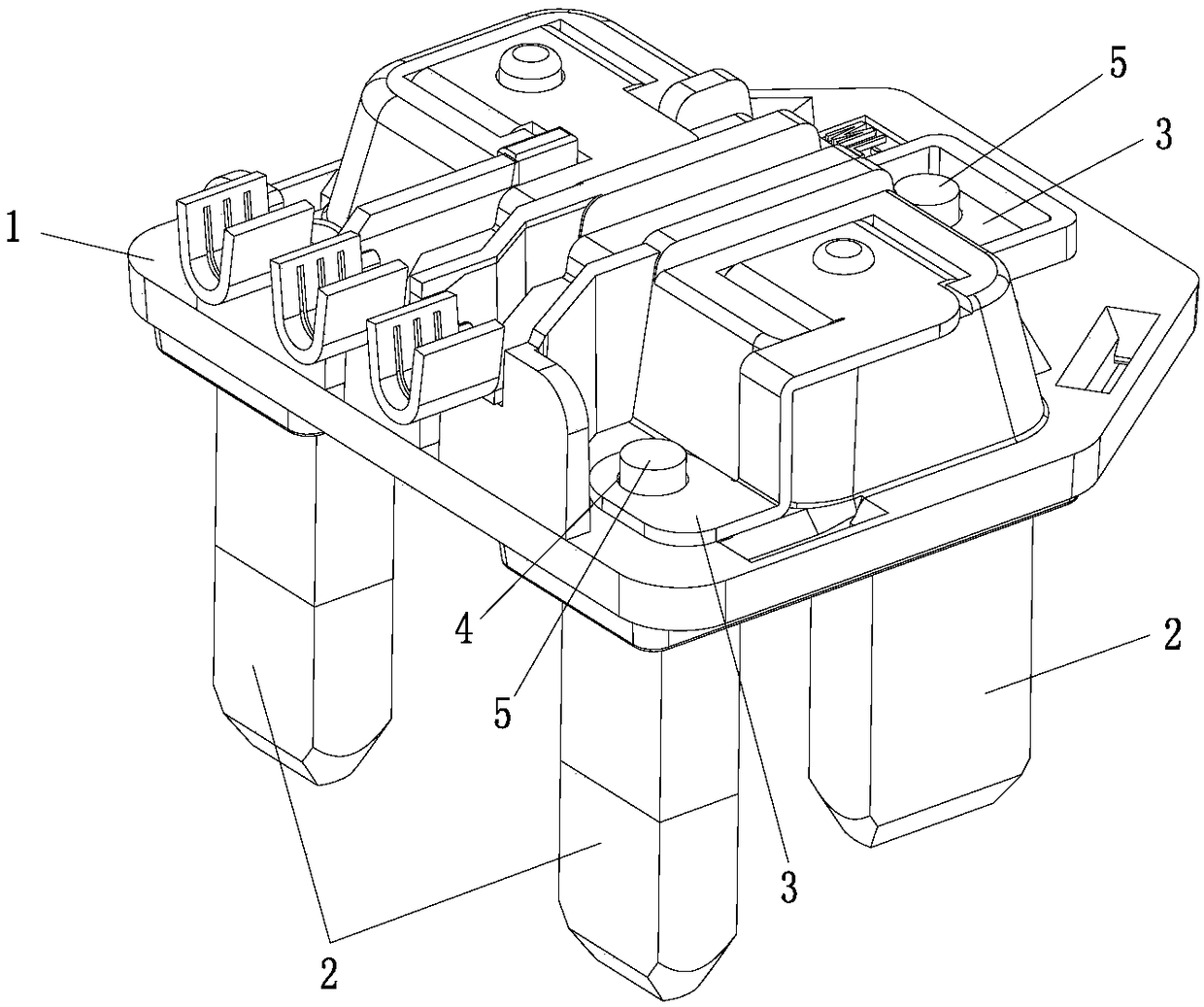

[0025] Such as figure 1 As shown, a new type of riveted British standard plug includes an inner frame 1, an electrical pin 2 is connected to the inner frame 1, each electrical pin 2 is electrically connected to a terminal piece 3, and a connecting hole is provided on the terminal piece 3 4. The electric pin 2 is provided with a riveting part 5 inserted into the connection hole 4, and the steps are as follows:

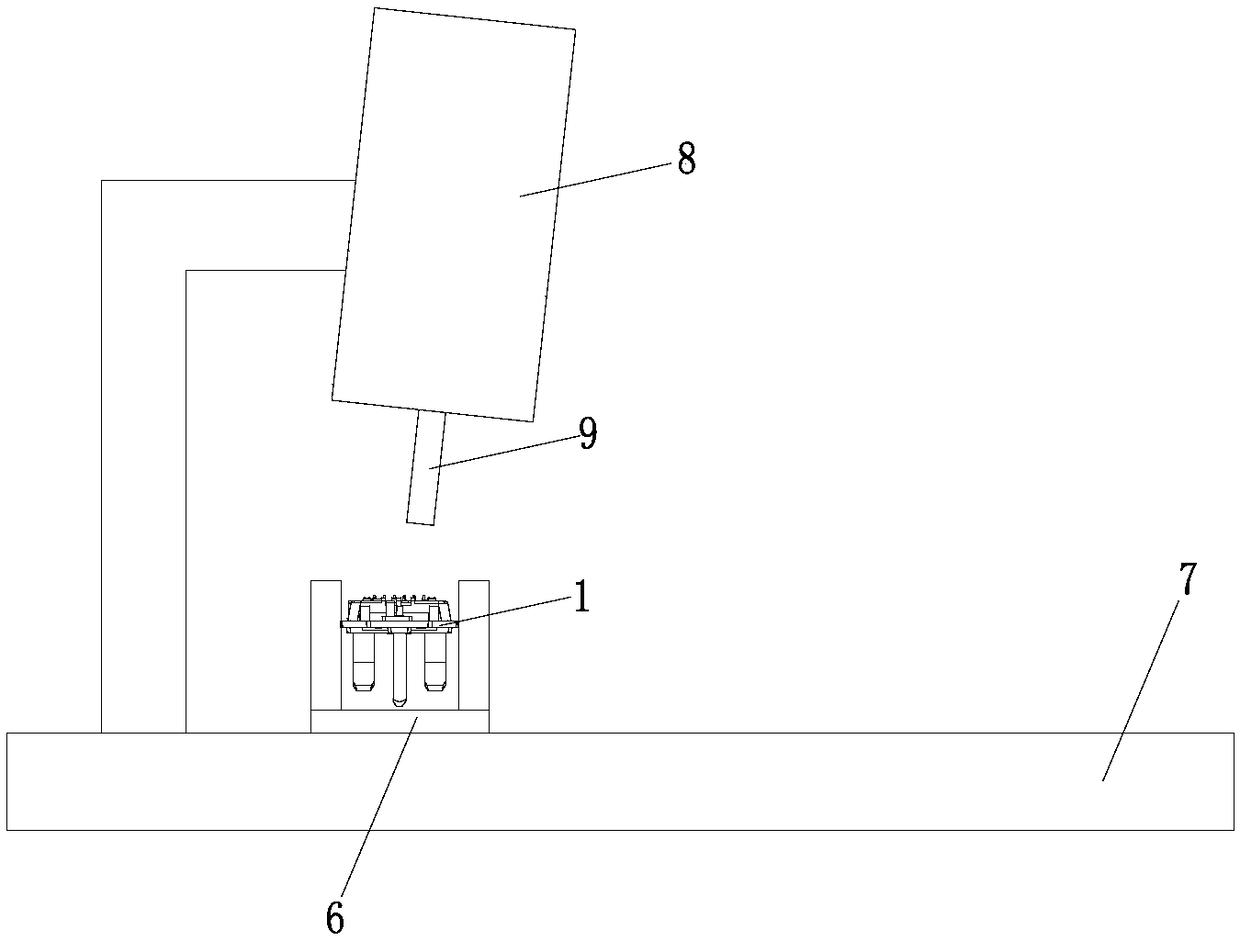

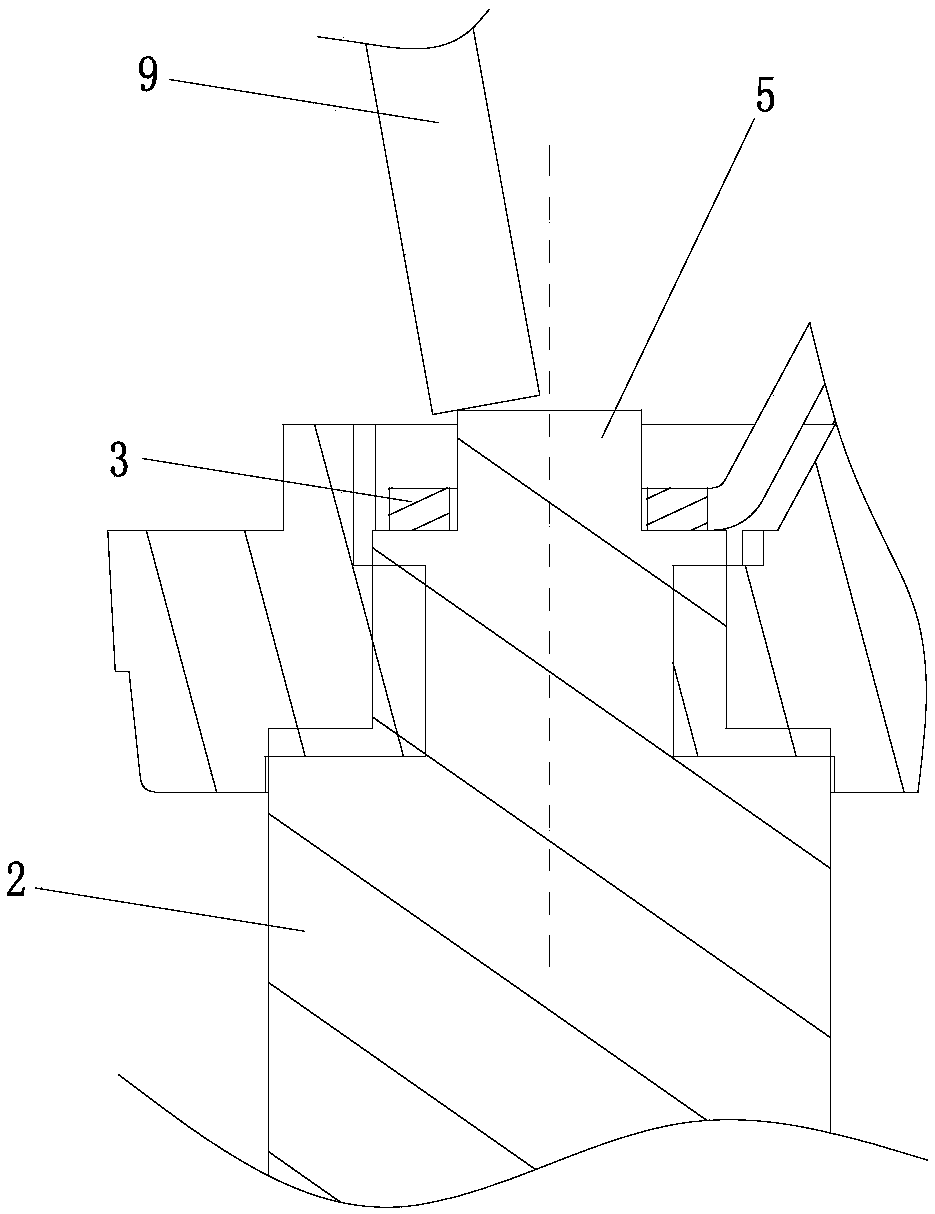

[0026] One, such as Figure 2 to Figure 3 As shown, the inner frame 1 is installed on the first workbench 7 provided with the riveting jig 6, the riveting device 8 is arranged above the riveting jig 6, and the riveting head 9 at the bottom of the riveting device 8 is pressed against the riveting part 5 top; it can fix the inner frame 1 to prevent the inner frame 1 from shifting during processing.

[0027] Two, if Figure 4 As shown, the spin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com