Forming die for piston valve plate

A technology for forming molds and piston valves, which is used in casting molding equipment, cores, and casting molds, etc., can solve the problems of piston valve valve sheet size not meeting production requirements, unfavorable cooling and heat dissipation of castings, and reducing product qualification rate. Conducive to heat dissipation and rapid cooling, reducing product qualification rate, not easy to loosen and collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

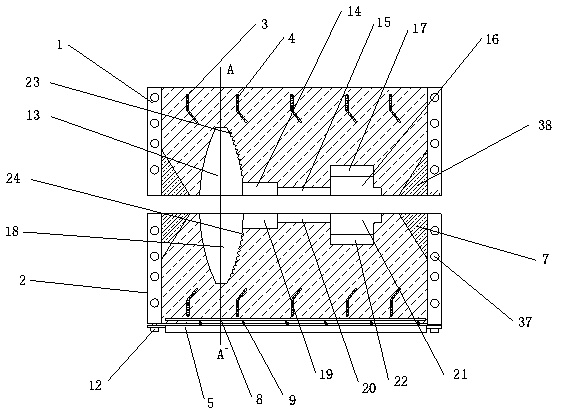

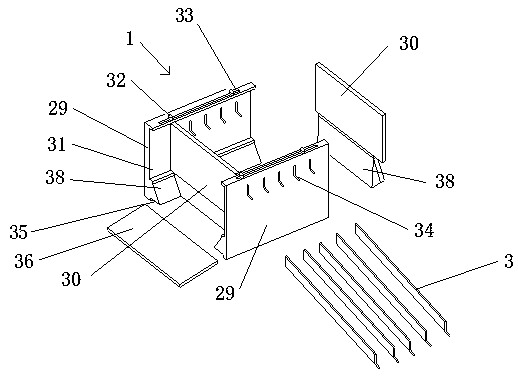

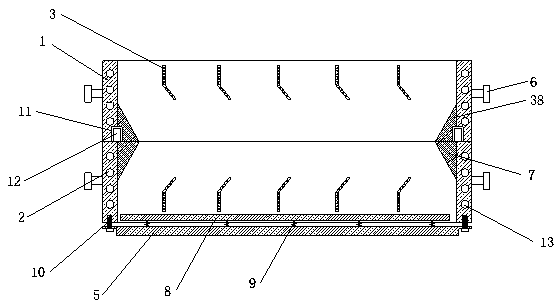

[0028] Embodiment: a kind of piston valve valve plate molding die, as attached Figure 1-5 As shown, it includes an upper sand box 1 and a lower sand box 2; the upper sand box 1 and the lower sand box 2 are both internally hollow and the upper and lower bottom surfaces are open box structures, and the upper sand box 1 and the lower sand box are open. The side walls of the lower flask 2 are provided with second cooling passages 37 to facilitate cooling of the molding sand, thereby increasing the cooling rate of the casting. The upper end of the inner cavity of the upper sand box 1 and the lower end of the inner cavity of the lower sand box 2 are respectively provided with a plurality of curved partition plates 3, and each partition plate 3 is provided with a plurality of first and second walls that run through the two ends of the partition plate 3. A cooling passage 4; the partition plate 3 includes a base plate, and the end of the base plate is provided with a bent plate; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com