Milling tool for small slot machining

A milling tool and slot machining technology, applied in milling cutting inserts, milling cutters, manufacturing tools, etc., can solve problems such as easy breakage, high production cost, and inability to meet market demands.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation, features and functions of the milling tool for machining small grooves according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

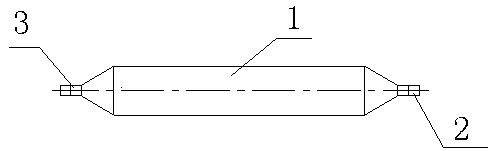

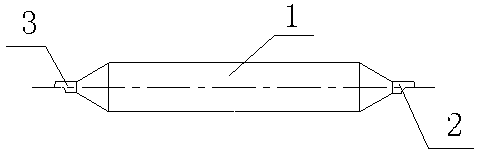

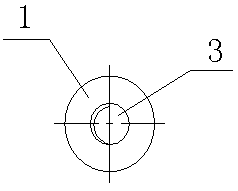

[0019] see Figure 1 to Figure 3 , a kind of milling tool for small groove processing of the present invention, comprises blade body 1, blade A2, blade B3, wherein: blade A2, blade B3 integrated with blade body 1 are respectively provided at the left and right ends of blade body 1.

[0020] The middle part of the blade body 1 is cylindrical, and the two ends are conical.

[0021] The cutting edge of the blade A2 is a half-opened meniscus.

[0022] The blade A2 can be fed radially or axially.

[0023] The cutting edge of the blade B3 is a half-opened meniscus.

[0024] The blade B3 can be fed radially or axially.

[0025] When in use, the middle part of the blade 1 is clamped on the machine tool as the clamping part. The cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com