Device for preventing negative ring duct piece from floating upwards in steel sleeve

A technology of negative ring segments and steel sleeves, which is applied in the field of devices for preventing negative ring segments from floating up in steel sleeves, and can solve problems such as difficult control of negative ring segment floating up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

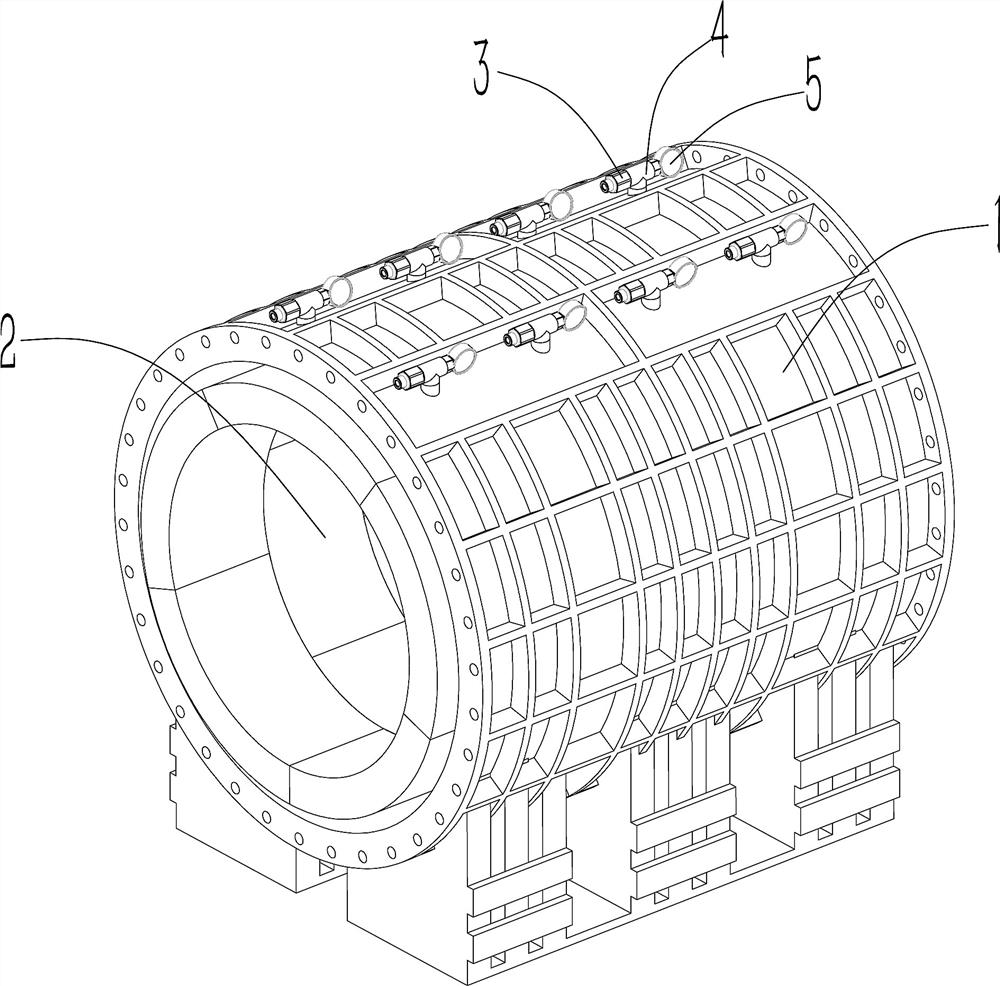

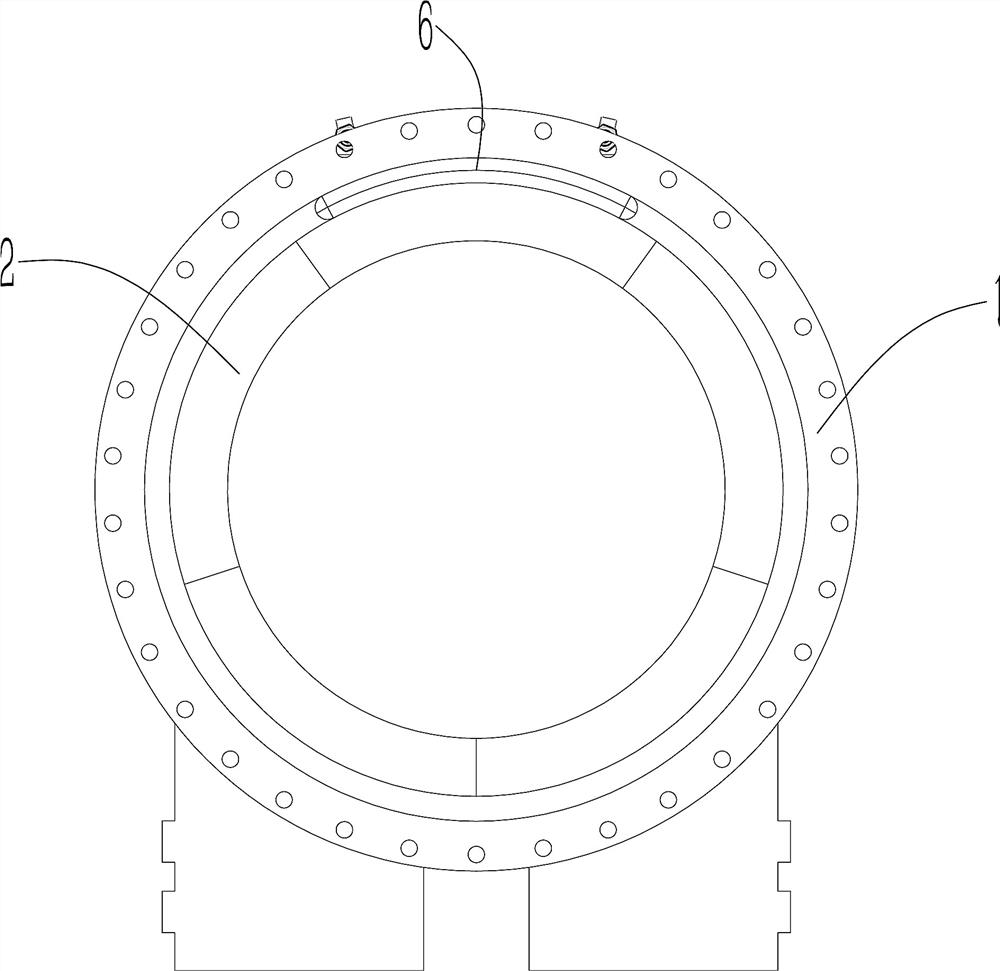

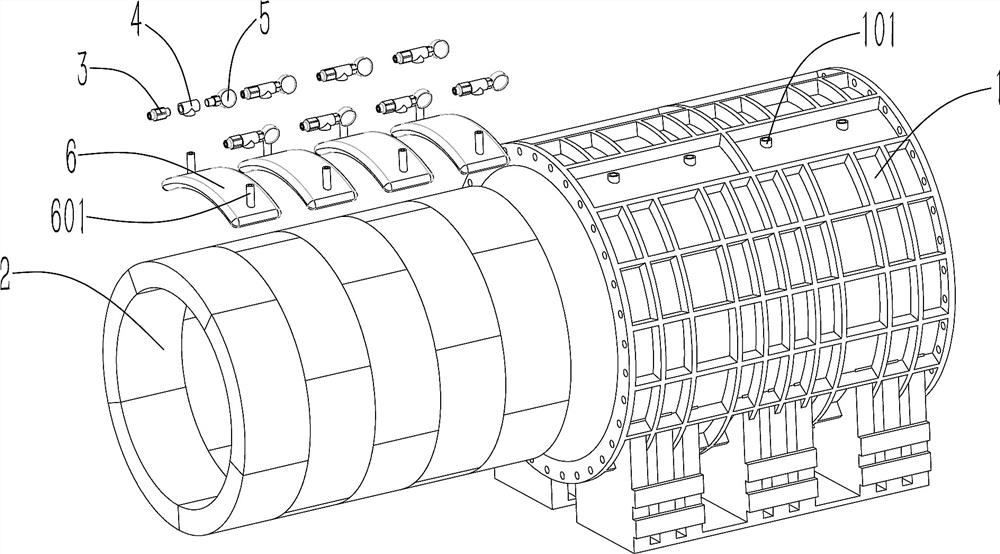

[0025] like Figure 1~5 As shown, the device for preventing the floating of the negative ring segment in the steel sleeve includes the negative ring segment 2 in the steel sleeve 1, a plurality of compression bags 6 are arranged between the steel sleeve 1 and the negative ring segment 2, and a plurality of The compression bag 6 is evenly arranged on the top of the inner wall of the steel sleeve 1, and the two sides of the compression bag 6 are provided with filling pipes 601, and the filling pipe 601 runs through the fixing hole seat 101 on the steel sleeve 1 and is sealed and fixed by the tee pipe 4. One end of the three-way pipe 4 is fixed with a pressure check valve 3, and the other end is fixed with a pressure gauge 5;

[0026] The filling material 8 is filled into the compression bag 6 through the pressure one-way valve 3, so that the plurality of compression bags 6 expand and fill the top gap between the steel sleeve 1 and the negative ring segment 2, thereby preventing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com