Multifunctional tool platform

A multi-functional, tool-based technology, applied to workbenches, manufacturing tools, etc., can solve problems such as single function, complicated operation procedures, and inconvenient movement, so as to reduce risk factors, improve productivity and work efficiency, and improve accuracy and convenience. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

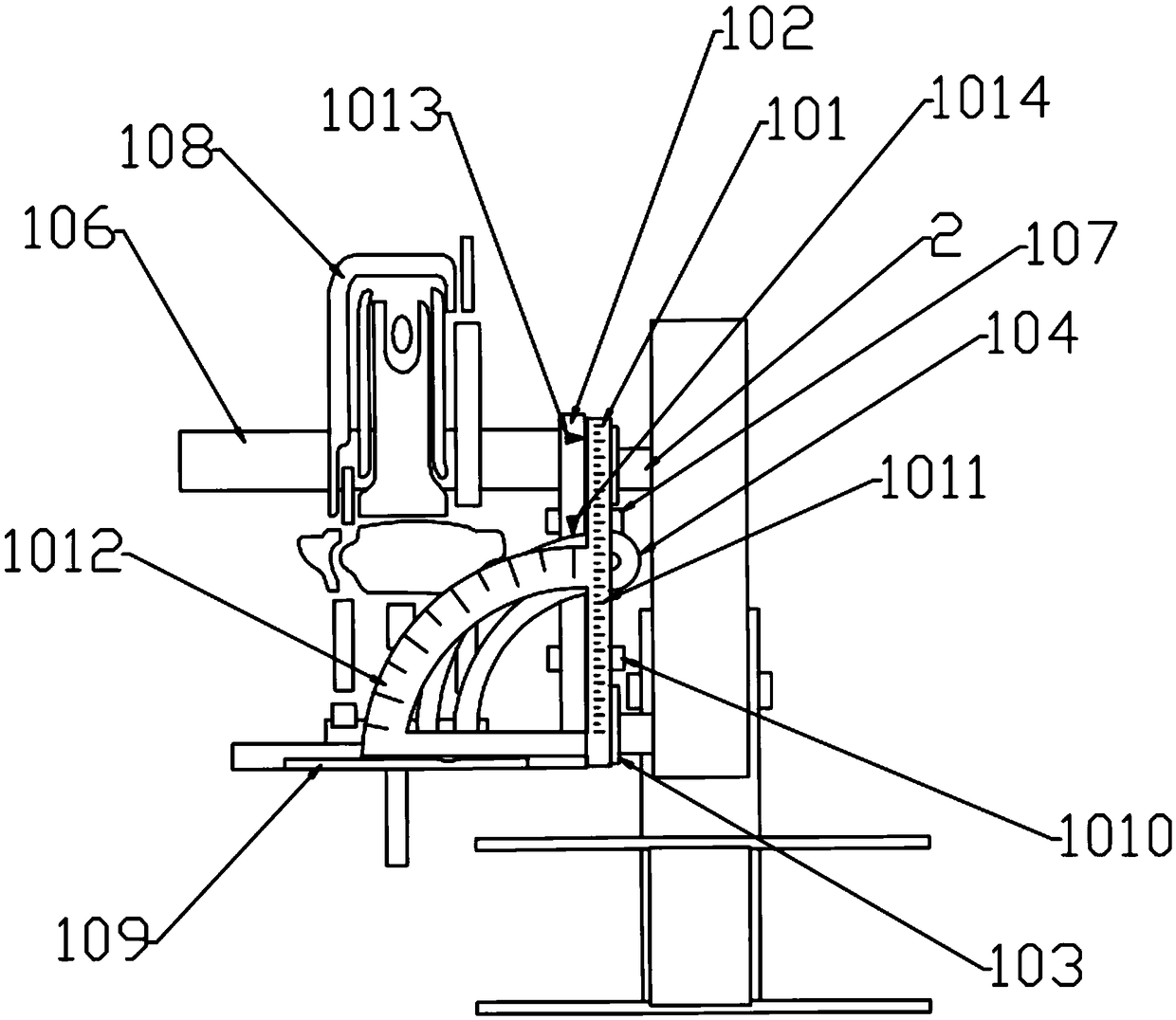

[0020] Such as Figure 4 As shown, a multifunctional tool platform is a guillotine type multifunctional tool platform, which includes a quick assembly assembly 1 and a quick assembly assembly slide rail 2. The quick assembly assembly slide rail 2 is provided with a scale. The quick assembly assembly slide rail 2 is provided with a quick assembly limit block 8. The quick assembly assembly 1 includes a connecting plate 101 and an L-shaped bracket 102. The connecting plate 101 slides through a precision slider 103 It is arranged on the slide rail 2 of the quick assembly assembly, the connecting plate 101 is fixedly provided with a rotary slide groove 104, and the vertical end side of the L-shaped bracket 102 is provided with a rotary slide bar 105. The rotary slide groove 104 is sleeved outside the rotary slide bar 105, the L-shaped bracket 102 is provided with a push-pull handle 106, and the L-shaped bracket 102 and the connecting plate 101 are provided with a rotation limit belt ...

Embodiment 2

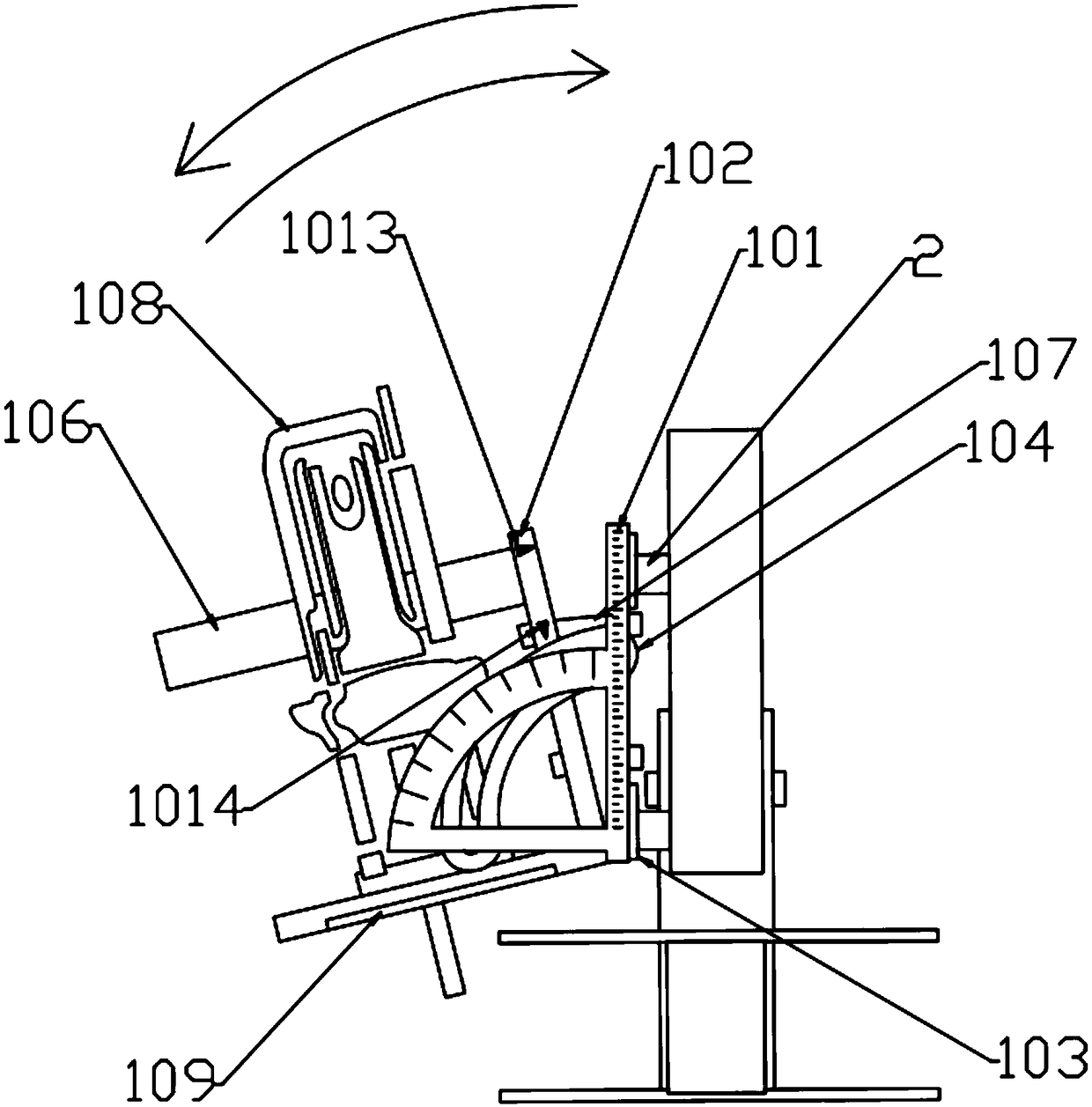

[0022] A multifunctional tool platform, which is a gantry multifunctional tool platform, includes a quick assembly assembly 1 and a quick assembly assembly slide rail 2. The quick assembly assembly slide rail 2 is provided with a scale. The assembly slide rail 2 is provided with a quick assembly limit block 8. The quick assembly assembly 1 includes a connecting plate 101 and an L-shaped bracket 102. The connecting plate 101 is slidably arranged at the place through a precision slider 103. On the slide rail 2 of the quick assembly assembly, the connecting plate 101 is fixedly provided with a rotary slide groove 104, the vertical end side of the L-shaped bracket 102 is provided with a rotary slide bar 105, and the rotary slide The groove 104 is sleeved outside the rotating slide bar 105, the L-shaped bracket 102 is provided with a push-pull handle 106, and the L-shaped bracket 102 and the connecting plate 101 are provided with a rotation limit belt 107, so The horizontal end surf...

Embodiment 3

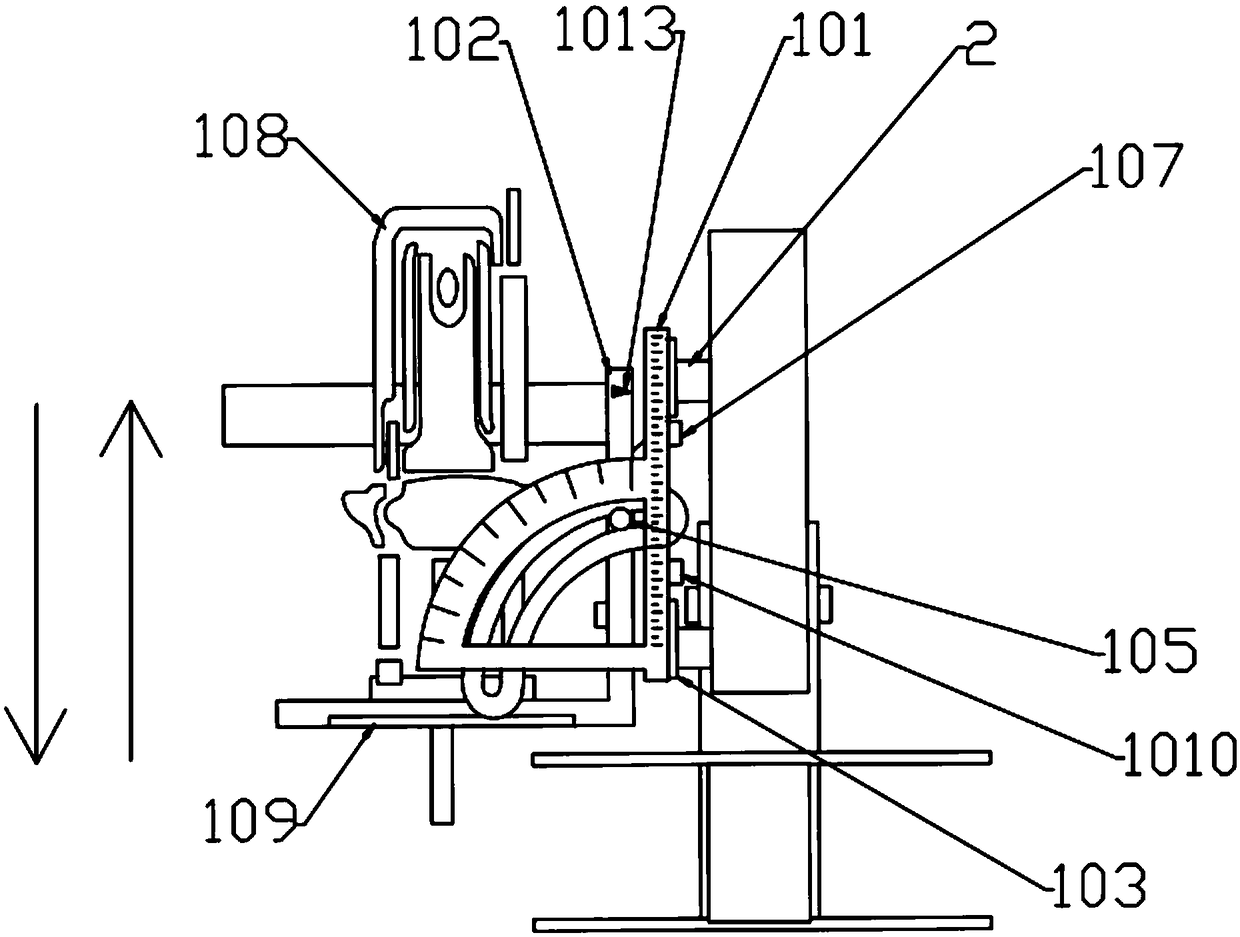

[0024] A multifunctional tool platform, which is a vertical wall-mounted multifunctional tool platform, includes a quick assembly assembly 1 and a quick assembly assembly slide rail 2. The quick assembly assembly slide rail 2 is provided with a scale. The quick assembly assembly slide rail 2 is provided with a quick assembly limit block 8. The quick assembly assembly 1 includes a connecting plate 101 and an L-shaped bracket 102. The connecting plate 101 slides through a precision slider 103 It is arranged on the slide rail 2 of the quick assembly assembly, the connecting plate 101 is fixedly provided with a rotary slide groove 104, and the vertical end side of the L-shaped bracket 102 is provided with a rotary slide bar 105. The rotary slide groove 104 is sleeved outside the rotary slide bar 105, the L-shaped bracket 102 is provided with a push-pull handle 106, and the L-shaped bracket 102 and the connecting plate 101 are provided with a rotation limit belt 107. The horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com