Mounting mold for precast beam wedge block and embedding bolts and construction method of mounting mold

A technology of pre-embedded bolts and prefabricated beams, applied in molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of poor appearance of the beam bottom, unfavorable support installation, low precision, etc., to save construction time and simplify the overall structure of the mold , the effect of improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

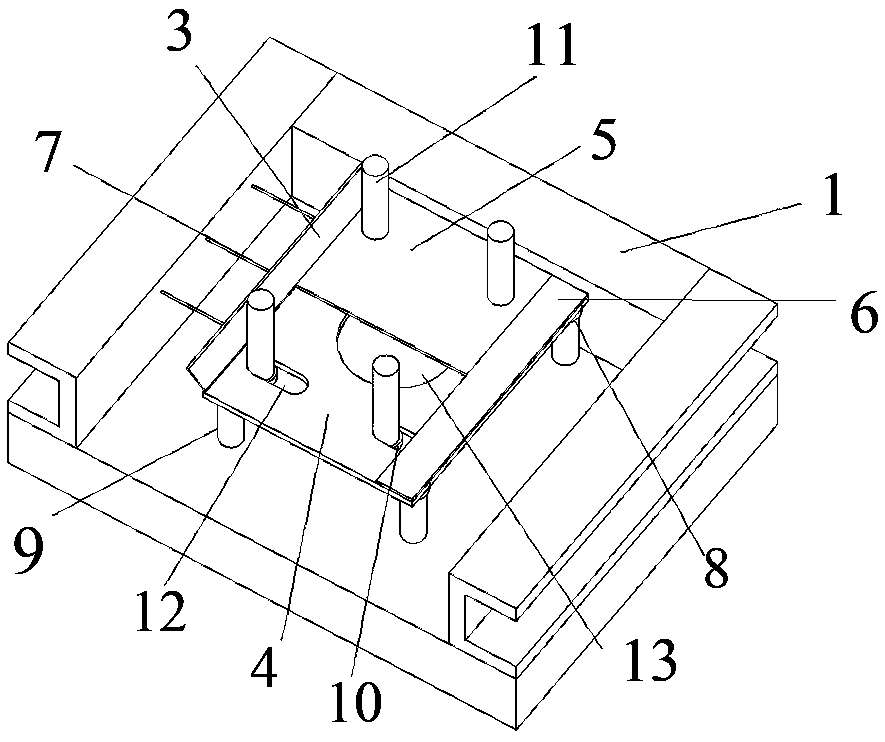

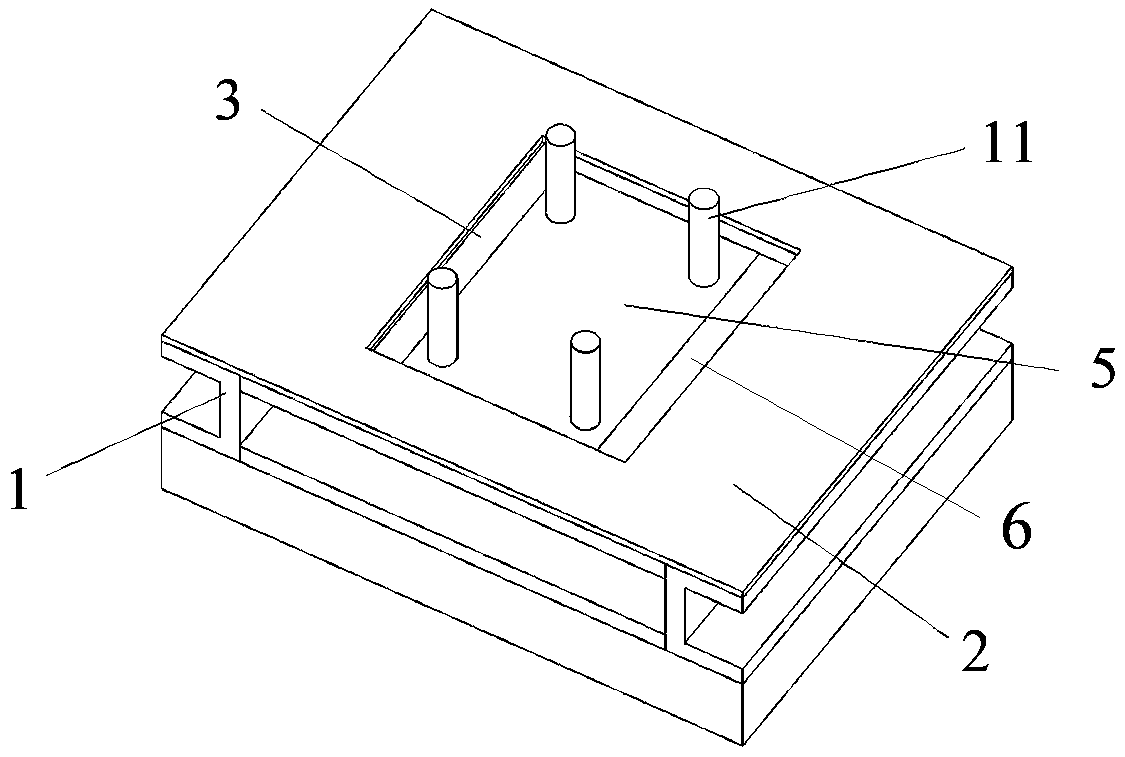

[0028] This embodiment is described by taking the wedge block and embedded bolt of the prefabricated box girder as an example, as figure 1 and figure 2 As shown, the rectangular frame 1 in the auxiliary mold is made of 20# channel steel closed and welded, the length is not less than 13000mm, the width is not small, the bottom width of the prefabricated beam is not small, and the composite plate 2 on the top surface of the rectangular frame 1 port is 5+1 composite steel plate , fixed by welding, in which the composite steel plate is reserved for the pre-embedded hole for installing the main mold; the inclined plate 3 is chamfered with a 50×50mm plate, and the support rod 7 welded with the channel steel is ø12 steel bar.

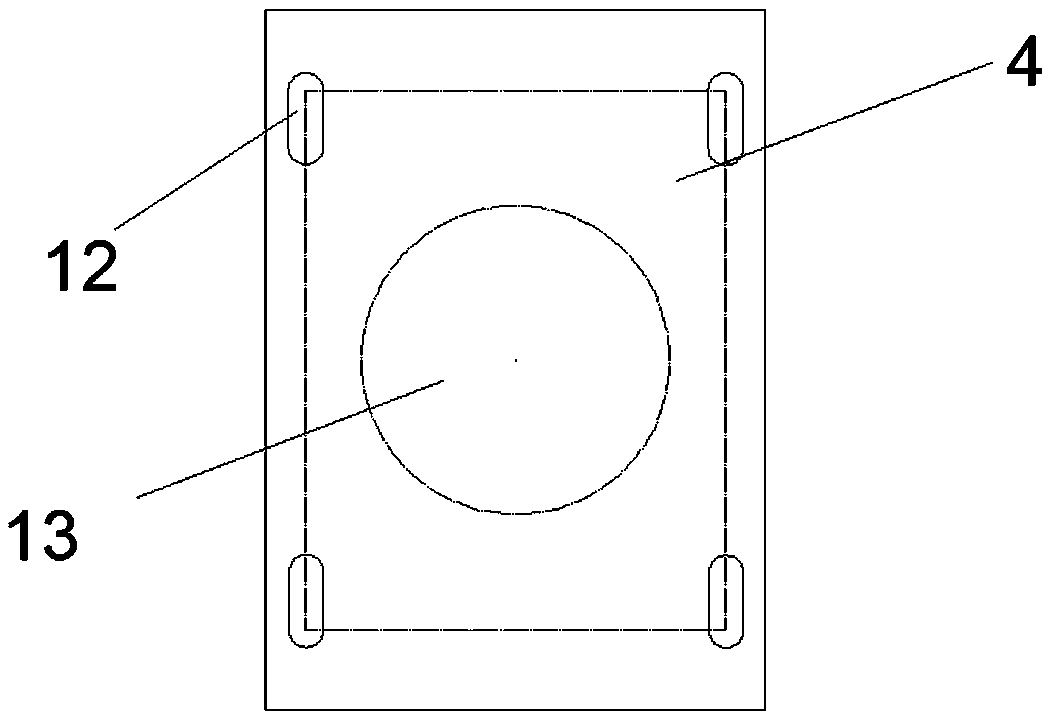

[0029] Such as image 3 and Figure 4 As shown, in this embodiment, the lower formwork 4 adopts a 2cm steel formwork with a size of 700 × 600mm, and an operation hole 13 with a diameter of 300mm is opened at the center of the 2cm steel formwork, and at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com