Method for manufacturing composite pipe fitting

A technology of pipe fittings and material pipes, which is applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve the problems of high product defect rate, deformation, and unstable composite material layer structure, so as to ensure structural stability and improve the good rate , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

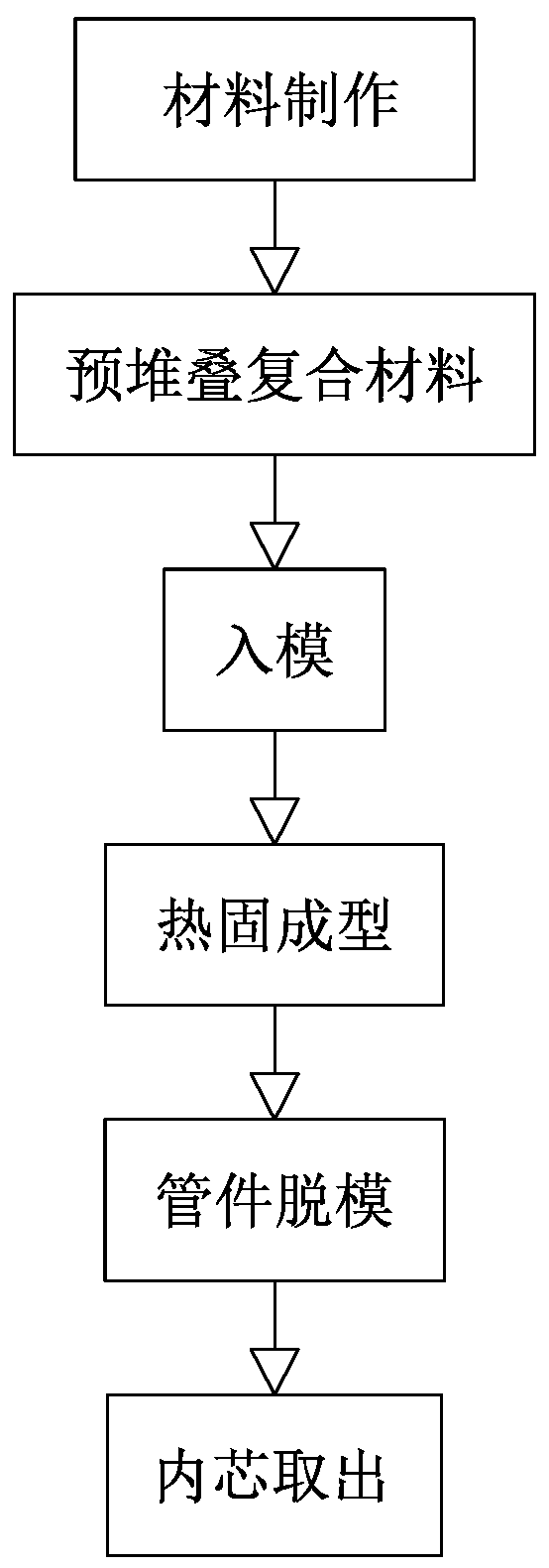

[0028] Such as figure 1 Shown, a kind of method for manufacturing composite pipe fittings, it comprises the following steps:

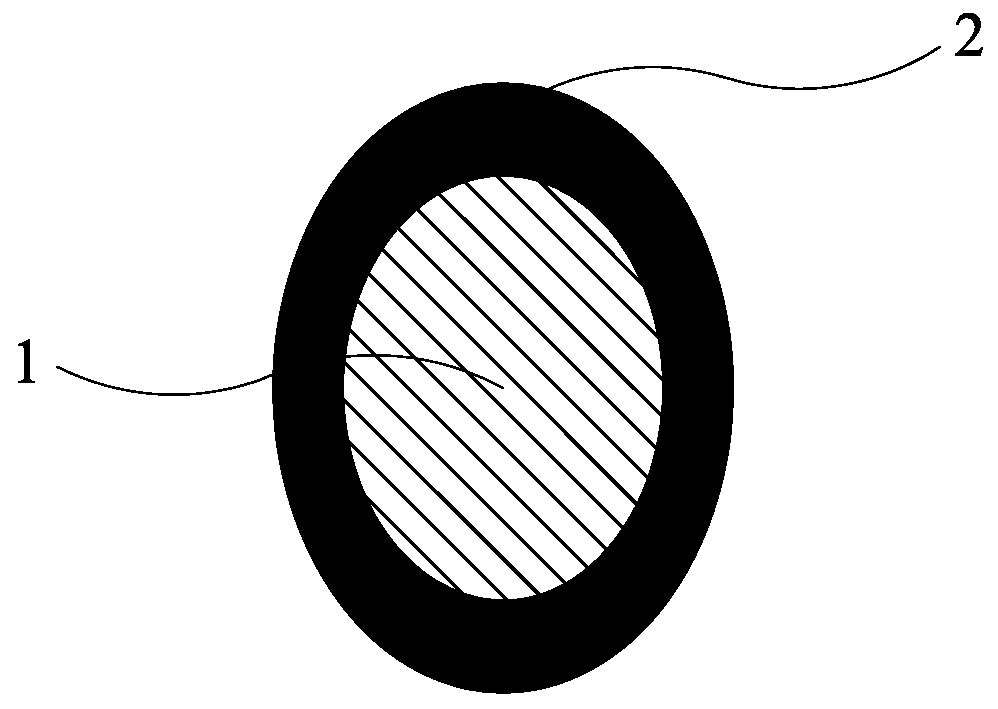

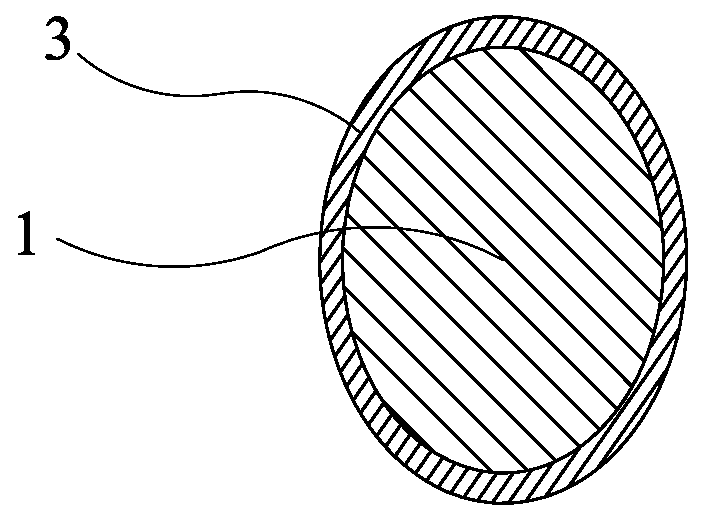

[0029] Step 1. Material production: form the polymer composite material into a sheet; heat and pressurize the fast-melting metal to liquefy it, pour it into a metal core mold, and then cool down to solidify it into a metal core whose shape matches the inner cavity of the pipe fitting 1 , and then the metal core 1 is obtained by demoulding;

[0030] Step 2, pre-stacked composite materials: such as figure 2 As shown, several layers of composite materials are stacked on the outer surface of the metal core 1 to form a preformed pipe fitting;

[0031] Step 3, mold entry: place the preformed pipe fitting in the cavity of the pipe fitting mold, and close the mold;

[0032] Step 4, thermos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com